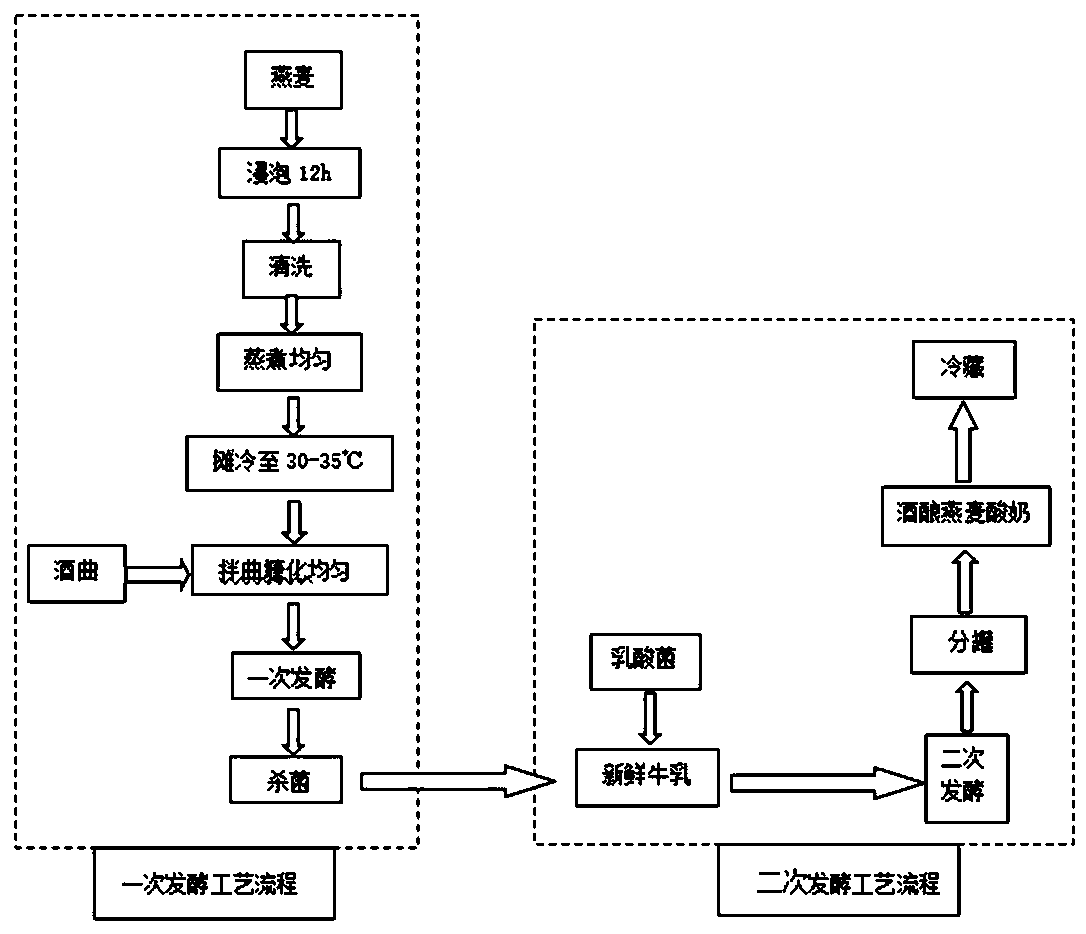

Preparation method of fermentation type oat dairy product

A dairy product and fermented technology, which is applied in the field of fermented oat milk product preparation, can solve the problems of incomplete conversion of nutrients into absorbable components and single form of oat deep-processing products, and achieve good flavor, delicate taste and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a fermented oat milk product, comprising the steps of:

[0035] A: Soak the oats in warm water at a temperature of 30°C for 30 minutes, wash them with clean water, and cook them at 100°C for 40 minutes to obtain steamed oats, then cool the steamed oats to 35°C; mix the steamed oats with The mass ratio of Angel sweet wine koji is 900:1, and the sweet embryos are obtained after mixing and fermenting at 35°C for 10hh. The sweet embryos prepared above are placed in a pasteurized tank at 85°C, kept for 15min, and then rapidly cooled to 4°C;

[0036] B: Set the concentration to 2.0×10 6 Mix CFU / mL Bifidobacterium lactis BB-12 with sterilized raw milk at a mass ratio of 1:1000 to obtain a raw milk mixed bacterial solution; then mix raw milk mixed bacterial solution with white sugar at a mass ratio of 20:1 After homogenization, add the sweet embryo prepared in step A of the same quality as raw milk to carry out fermentation. The fermentation temperature...

Embodiment 2

[0039] A method for preparing a fermented oat milk product, comprising the steps of:

[0040] A: Soak the oats in warm water at a temperature of 30°C for 30 minutes, wash them with clean water, and cook them at 100°C for 40 minutes to obtain steamed oats, then cool the steamed oats to 40°C; The mass ratio of Qitian wine koji is 1000:1, and the sweet embryos are obtained after mixing and fermenting at 40°C for 11 hours. Put the prepared sweet embryos in a pasteurization tank at 85°C for 15 minutes, and then quickly cool to 4°C;

[0041] B: Set the concentration to 2.0×10 6 CFU / mL Bifidobacterium lactis BB-12 was mixed with raw milk obtained from sterilized raw milk at a ratio of 1:1000; then the raw milk mixed bacteria liquid and white sugar were mixed at a mass ratio of 25:1, and then added with Fermentation is carried out in the sweet embryos prepared in step A of the quality of raw milk, and the fermentation temperature is 30°C for 11 hours under constant temperature condit...

Embodiment 3

[0044] A method for preparing a fermented oat milk product, comprising the steps of:

[0045] A: Soak the oats in warm water at 30°C for 12-14 hours, wash them with clean water, and cook them at 110°C for 40 minutes to obtain steamed oats, then cool the steamed oats to 45°C; The mass ratio of Angel sweet wine koji is 1100:1, and the sweet embryos are obtained after mixing and fermenting at 45°C for 10h-12h, and the sweet embryos prepared above are placed in a pasteurization tank at 85°C, kept for 15min, and then rapidly cooled to 4°C to obtain primary fermentation products;

[0046] B: Set the concentration to 2.0×10 6 CFU / mL Bifidobacterium lactis BB-12 was mixed with raw milk obtained from sterilized raw milk at a ratio of 1:1000; then the raw milk mixed bacteria liquid and white sugar were mixed at a mass ratio of 30:1, and then added with Fermentation is carried out in the sweet embryos prepared in step A of the quality of raw milk, and the fermentation temperature is 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com