Anti-oxidation linseed oil microcapsules and preparation method thereof

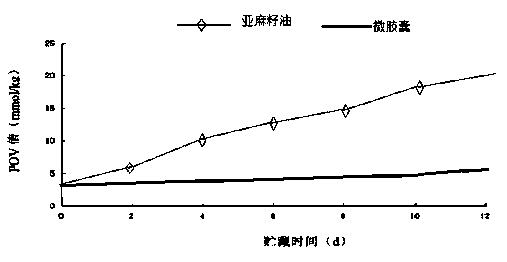

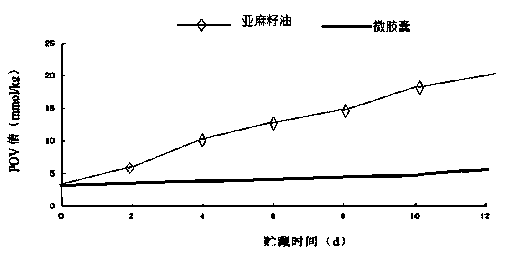

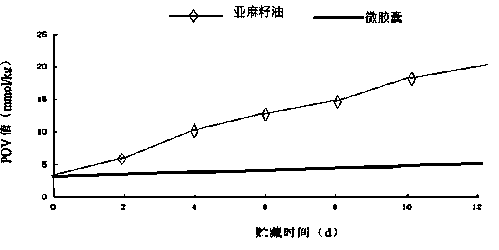

A technology for oxidizing linseed and linseed oil, which is applied in the direction of food ingredients as antioxidants, food ingredients as antimicrobial preservation, food homogenization, etc. It can solve the problems that linseed oil is easy to oxidize and deteriorate, difficult to preserve, and affects the taste. , to achieve the effect of improving taste, high production efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An antioxidant linseed oil microcapsule, which is composed of the following raw materials in parts by mass: 30 parts of linseed oil, 10 parts of pumpkin seed oil, 10 parts of walnut oil, 8 parts of garlic essential oil, 2 parts of stabilizer, and 20 parts of emulsifier , 30 parts of wall material, 5 parts of corn starch, 2 parts of antioxidant, 2 parts of preservative, 3 parts of rice protein, 5 parts of vitamin C; The antioxidant is selected from ascorbyl palmitate; The preservative is selected from p-hydroxy ethyl benzoate;

[0026] The stabilizer is selected from calcium stearoyl lactylate.

[0027] A preparation method of antioxidant linseed oil microcapsules, the preparation steps are as follows:

[0028] (1) Pour the wall material, cornstarch, antioxidant, preservative, and stabilizer into the mixer in sequence, add 50 parts by mass of water, heat to 60°C, keep warm and stir at high speed for 20 minutes to completely dissolve , to prepare mixture A;

[0029] (2...

Embodiment 2

[0035] An antioxidant linseed oil microcapsule, which is composed of the following raw materials in parts by mass: 60 parts of linseed oil, 30 parts of pumpkin seed oil, 25 parts of walnut oil, 16 parts of garlic essential oil, 10 parts of stabilizer, and 40 parts of emulsifier , 60 parts of wall materials, 15 parts of cornstarch, 16 parts of antioxidants, 8 parts of preservatives, 8 parts of rice protein, 15 parts of vitamin C; the antioxidant is selected from 2 parts of ascorbyl palmitate, 3 parts of butylated hydroxyanisole The preservative is selected from 4 parts of ethyl p-hydroxybenzoate and 2 parts of sodium benzoate; the stabilizer is selected from sodium stearoyl lactylate. A preparation method of antioxidant linseed oil microcapsules, the preparation steps are as follows:

[0036] (1) Pour the wall material, cornstarch, antioxidant, preservative, and stabilizer into the blender in sequence, add 90 parts by mass of water, heat to a temperature of 80°C, keep warm and ...

Embodiment 3

[0043]An antioxidant linseed oil microcapsule, which is composed of the following raw materials in parts by mass: 40 parts of linseed oil, 20 parts of pumpkin seed oil, 20 parts of walnut oil, 12 parts of garlic essential oil, 8 parts of stabilizer, and 30 parts of emulsifier , 40 parts of wall materials, 12 parts of corn starch, 14 parts of antioxidants, 6 parts of preservatives, 5 parts of rice protein, 10 parts of vitamin C; the antioxidant is selected from tertiary butyl hydroquinone; the preservative is selected from From 2 parts of p-hydroxybenzoic acid, 1 part of ethyl ester, and 1 part of sodium benzoate; the stabilizer consists of 2 parts of calcium stearoyl lactylate, 1 part of sodium stearoyl lactylate, 2 parts of calcium hydrogen phosphate, 2 parts of sodium alginate, Composed of 1 part of carboxymethyl cellulose (CMC) and 2 parts of sodium carboxymethyl cellulose (CMC-Na).

[0044] A preparation method of antioxidant linseed oil microcapsules, the preparation step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com