A kind of desulfurization absorbent and its preparation method and application

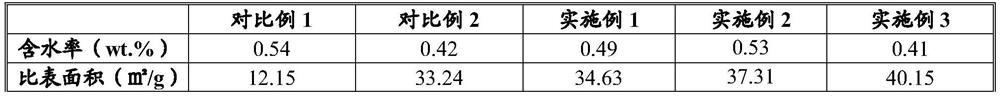

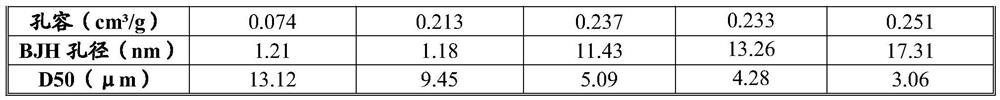

An absorbent and reaction technology, applied in the field of desulfurization absorbent and its preparation, can solve the problems of low desulfurization activity, waste of resources, lack of overall management and standard mechanism, etc., and achieve the effect of large specific surface area, large pore volume, and excellent desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the desulfurization absorbent described in the above technical solution, comprising the following steps:

[0038] a) quicklime, water-retaining agent, cell agent and water are mixed and reacted to obtain a digested product;

[0039] b) drying the digested product to obtain a desulfurization absorbent.

[0040] In the preparation method provided by the invention, quicklime, water retaining agent, cell agent and water are firstly mixed for digestion. Wherein, the mass ratio of the quicklime to water is preferably 1000:(300~1000), specifically 1000:300, 1000:400, 1000:500, 1000:600 or 1000:700; the temperature of the water is preferably 0-50°C, specifically 10°C, 20°C, 30°C, 40°C, 50°C. In the present invention, it is preferred to firstly mix the water-retaining agent, the cell agent and water to obtain an aqueous solution; then the quicklime and the aqueous solution are mixed and reacted. In the present invention...

Embodiment 1

[0055] Grinding quicklime (CaO content 85-95wt%) and sieving to obtain calcium oxide powder with a particle size larger than 100 mesh. Add 100 parts by weight of calcium oxide powder to a mixed solution of 40 parts by weight of water (about 20° C.), 0.2 parts by weight of sodium carboxymethylcellulose and 1 part by weight of n-pentane. Stir at 500r / min for 1min, then adjust the rotation speed to 200r / min, continue stirring for 4min, and air-dry the obtained product at 200°C until the moisture content is <1%, to obtain a desulfurization absorbent.

Embodiment 2

[0057] Grinding quicklime (CaO content 85-95wt%) and sieving to obtain calcium oxide powder with a particle size larger than 100 mesh. Add 100 parts by weight of calcium oxide powder to a mixed solution of 40 parts by weight of water (about 20° C.), 0.3 parts by weight of sodium lignosulfonate and 1.2 parts by weight of cyclopentane. Stir at 300r / min for 1min, then adjust the rotation speed to 200r / min, continue stirring for 4min, and air-dry the obtained product at 200°C until the moisture content is less than 1%, to obtain a desulfurization absorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com