Preparation method for porphyrin-functionalized titanium dioxide-montmorillonite nano-complex

A nanocomposite, titanium dioxide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, special compound water treatment, etc., can solve the problem of reduced chemical active sites, large band gap, and reduced activity and other issues to achieve the effect of increasing catalytic efficiency, improving catalytic efficiency, and enhancing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

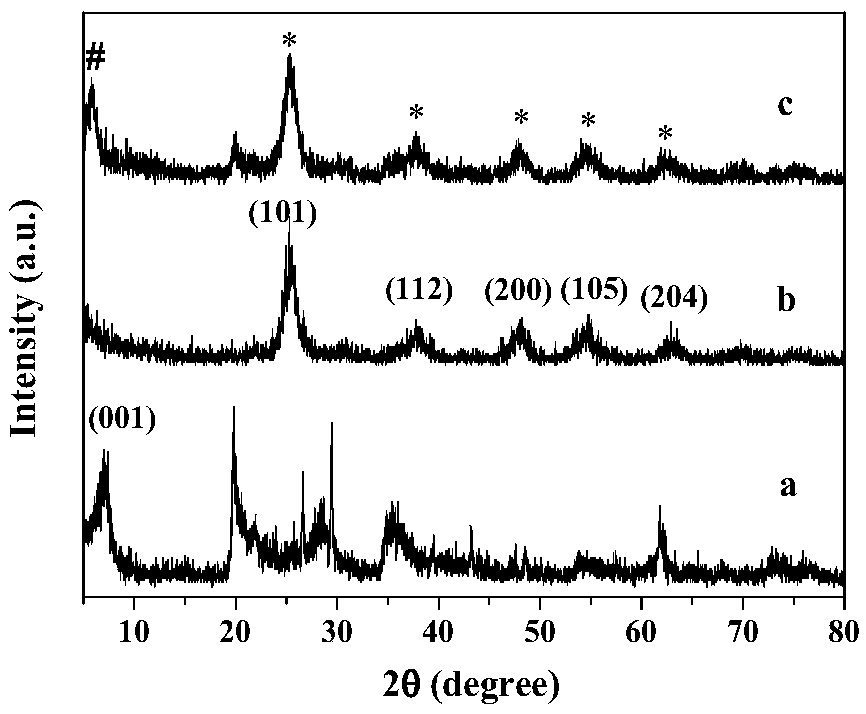

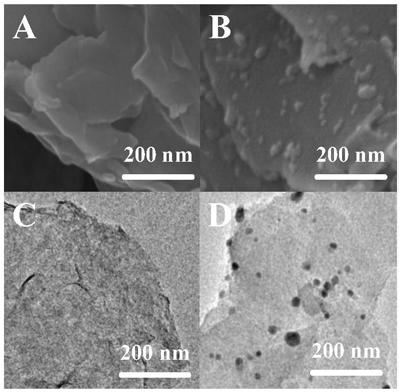

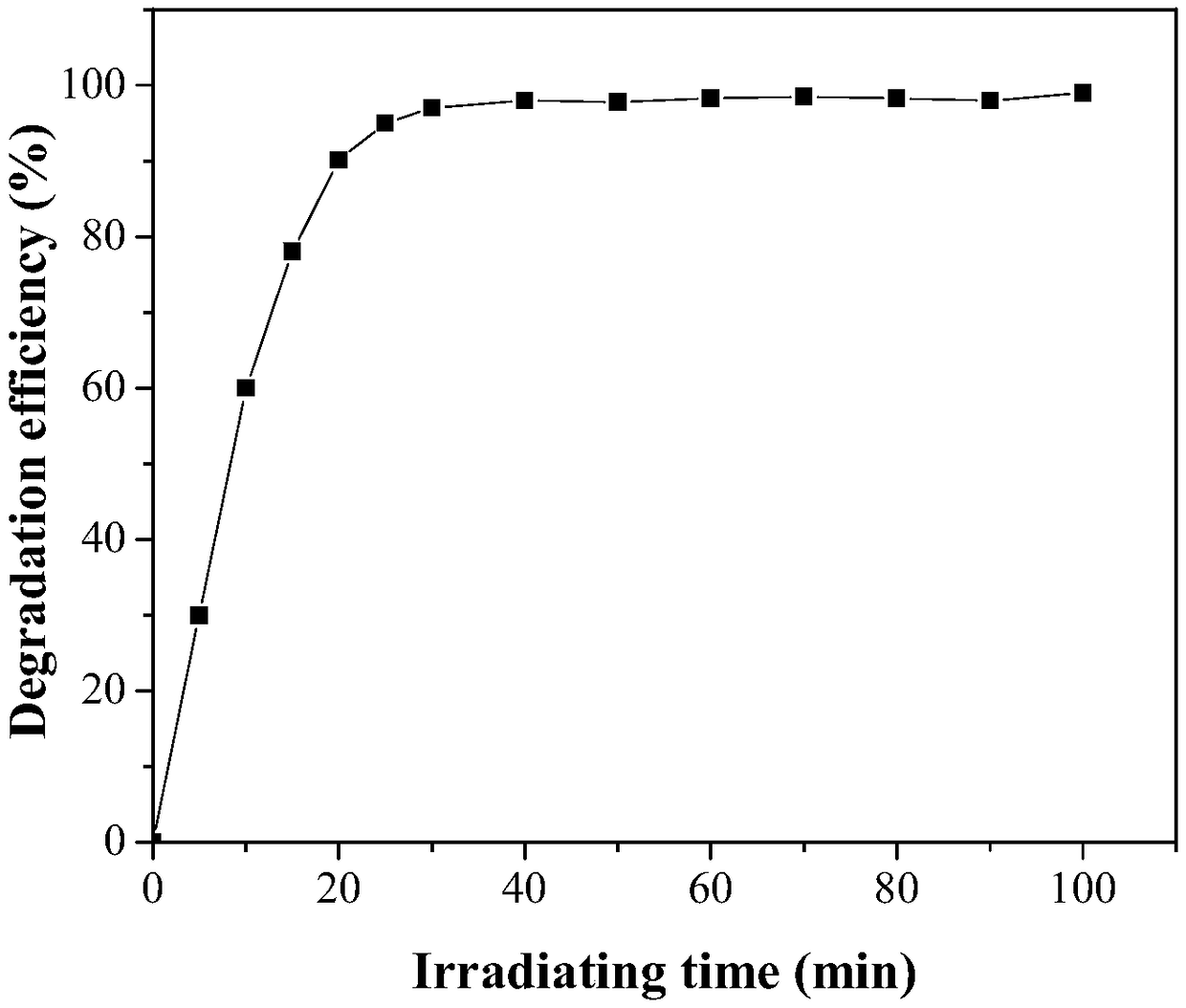

Embodiment 1

[0036] 5g of montmorillonite, 5g of butyl titanate, 2.5g of tetracarboxyphenylporphyrin and 5g of absolute ethanol were selected as raw materials. First add butyl titanate to absolute ethanol, and stir magnetically at room temperature to obtain a transparent solution I. The magnetic stirring speed is 200r / min, and the magnetic stirring time is 90 minutes. Slowly add the transparent solution I dropwise into the nitric acid solution (the concentration of the nitric acid solution is 1 mol / L), stir at room temperature to obtain a yellow transparent solution II, and control the pH value of the solution to 2.5. Add montmorillonite to 5 g of deionized water, and prepare montmorillonite suspension III through ultrasonic treatment and high-speed dispersion (dispersion speed 1000r / min). The solution II was slowly added dropwise to the montmorillonite suspension III, and stirred to obtain a white solution IV, the stirring temperature was controlled at 25°C, the stirring speed was 300r / mi...

Embodiment 2

[0039] 5g of montmorillonite, 2.5g of butyl titanate, 2.5g of tetracarboxyphenylporphyrin and 5g of absolute ethanol were selected as raw materials. First add butyl titanate to absolute ethanol, and stir magnetically at room temperature to obtain a transparent solution I. The magnetic stirring speed is 200r / min, and the magnetic stirring time is 60 minutes. Slowly add the transparent solution I dropwise into the nitric acid solution (the concentration of the nitric acid solution is 1 mol / L), stir at room temperature to obtain a yellow transparent solution II, and control the pH value of the solution to 2.5. Montmorillonite suspension III was prepared by adding montmorillonite to 5 g of deionized water, ultrasonic treatment, and high-speed dispersion (dispersion speed 1000 r / min). The solution II was slowly added dropwise to the montmorillonite suspension III, and stirred to obtain a white solution IV, the stirring temperature was controlled at 25°C, the stirring speed was 300r...

Embodiment 3

[0042]5g of montmorillonite, 10g of butyl titanate, 5g of tetracarboxyphenylporphyrin and 5g of absolute ethanol were selected as raw materials. First add butyl titanate to absolute ethanol, and stir magnetically at room temperature to obtain transparent solution I. The magnetic stirring speed is 200r / min, and the magnetic stirring time is 120 minutes. Slowly add the transparent solution I dropwise into the nitric acid solution (the concentration of the nitric acid solution is 1 mol / L), stir at room temperature to obtain a yellow transparent solution II, and control the pH value of the solution to 2.5. Add montmorillonite to 5 g of deionized water, and prepare montmorillonite suspension III through ultrasonic treatment and high-speed dispersion (dispersion speed 1000r / min). The solution II was slowly added dropwise to the montmorillonite suspension III, and stirred to obtain a white solution IV, the stirring temperature was controlled at 25°C, the stirring speed was 300r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com