Ultrathin black phosphorene non-metal promoter material, as well as preparation method and composite material of ultrathin black phosphorene non-metal promoter material

A technology of co-catalysts and composite materials, which is applied in the fields of catalyst activation/preparation, non-metallic elements, chemical instruments and methods, etc., can solve problems such as being easily oxidized, and achieve simple operation, universality, wide application prospects and use. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Ultrathin black phosphorene prepared by peeling off

[0032] Weigh 0.05g block BP and place it in a 100ml plastic beaker, add 50ml liquid nitrogen, put it in a vacuum flask, and freeze it for 2h. The block black phosphorus after freezing treatment is dispersed in the 99% 1-methyl-N-pyrrolidone (NMP) solution of 50ml, in the supersonic wave of 400W 4h; Centrifuge for 10 minutes; after removing the block BP that has not been successfully peeled off, transfer the obtained suspoemulsion to a centrifuge tube, put it into a vacuum freeze dryer, set the freezing temperature to -50°C, and vacuum freeze dry for 8 hours to finally obtain a fluffy black The powder is ultra-thin black phosphorene.

Embodiment 2

[0033] Example 2: Preparation of ultra-thin black phosphorene and photocatalyst composite material

[0034] Select photocatalyst 2D C 3 N 4 ; Weigh 50 mg of 2D C 3 N 4 Put it in a beaker, add 20ml 99% 1-methyl-N-pyrrolidone (NMP) solution, stir for 0.5h with high-purity argon, then add 2.5mg ultra-thin black phosphorene and stir for 24h; after stirring, centrifuge, ethanol After washing, the obtained precipitate was dried in a vacuum oven at 40°C; after drying, the resultant was calcined at 200°C for 2 hours under a high-purity argon atmosphere, and the final product was a composite material.

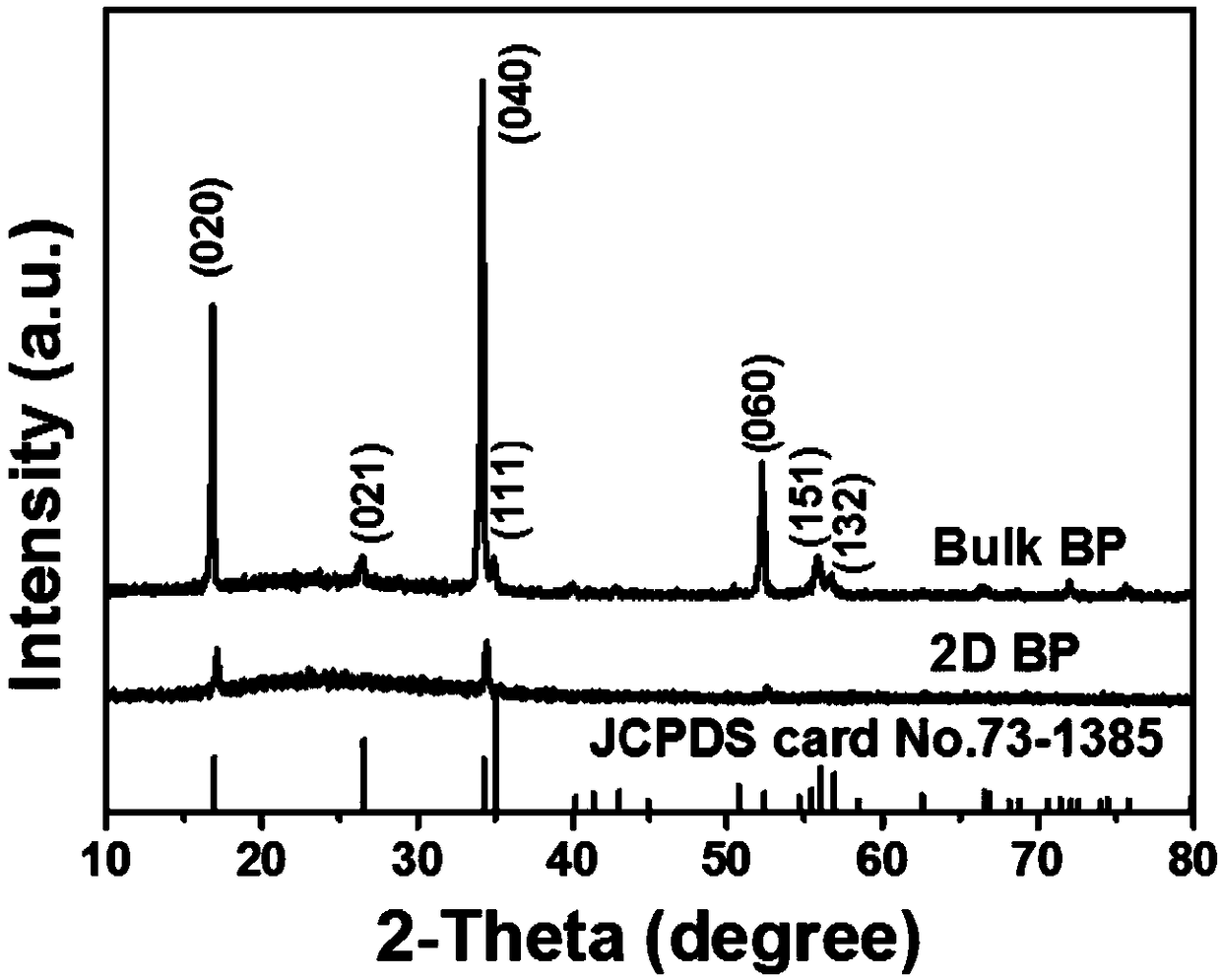

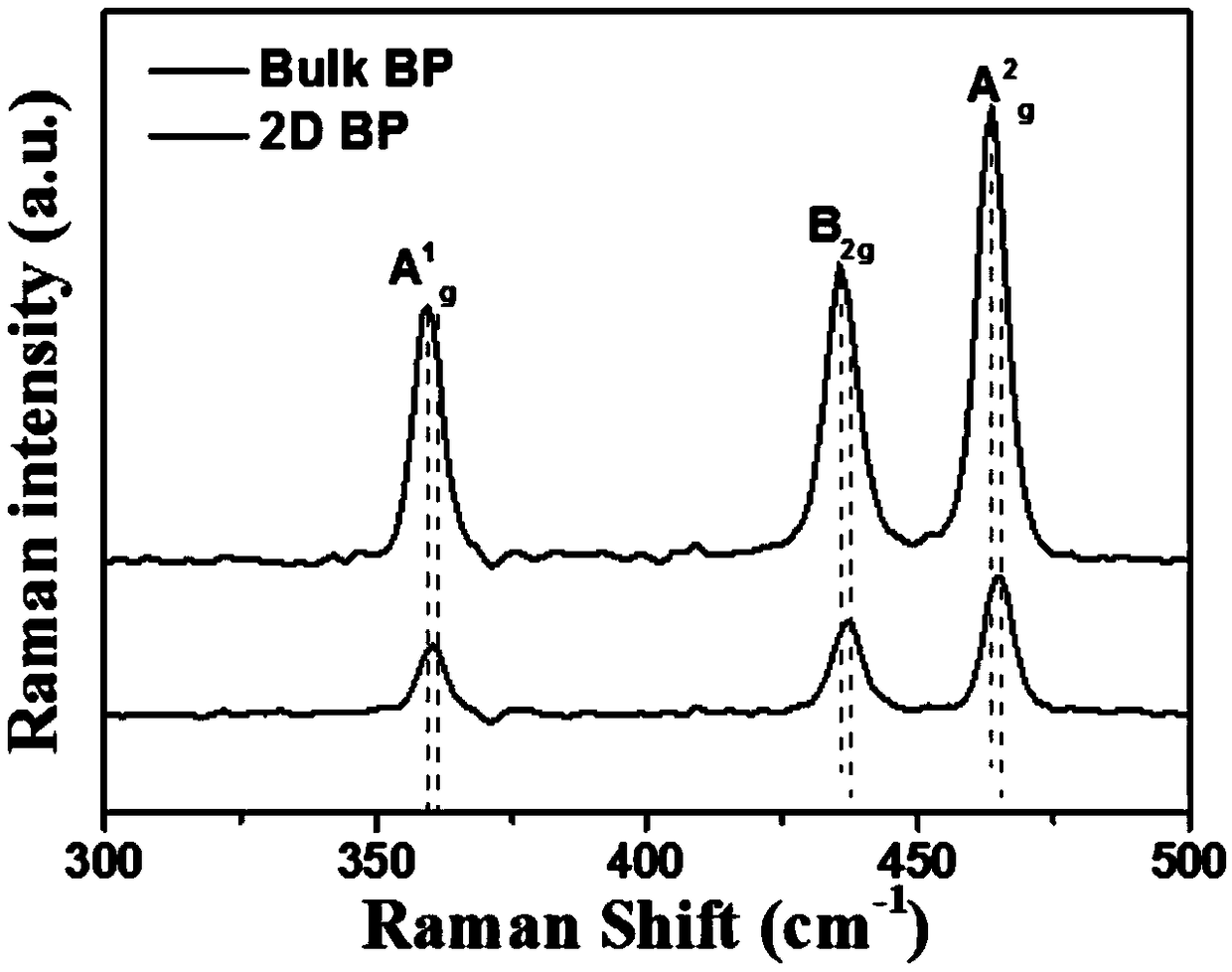

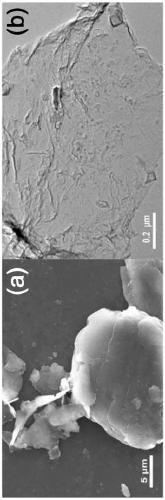

[0035] The structural test of the prepared ultrathin black phosphorene was carried out on a German Bruker D8 type ray diffractometer (XRD) (Cu-Kα ray, The range is 10°-80°), and its XRD pattern is as follows figure 1 shown. Depend on figure 1 It can be seen that BP has diffraction peaks at 17.3°, 34.5° and 52.6°, corresponding to (020), (040) and (060) crystal planes, respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com