Method for synthesizing single-layer transition metal chalcogenides

A technology of transition metal chalcogenides and compounds, applied in the direction of metal selenide/telluride, binary selenium/telluride compounds, etc., can solve the problems of high cost, sample damage, doping of impurities, etc., and achieve short synthesis time and low cost , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

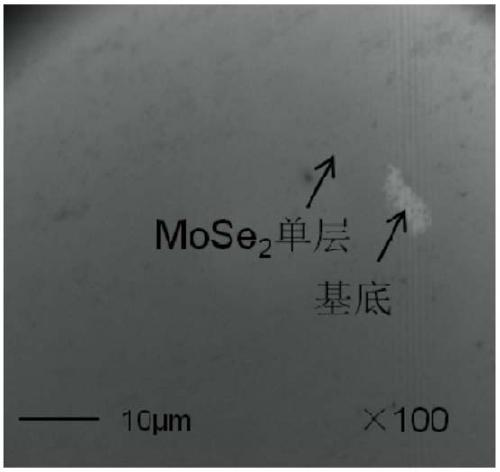

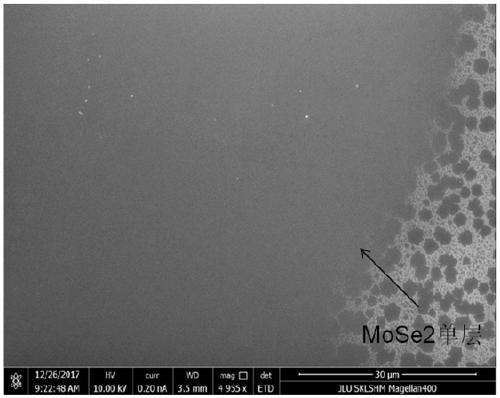

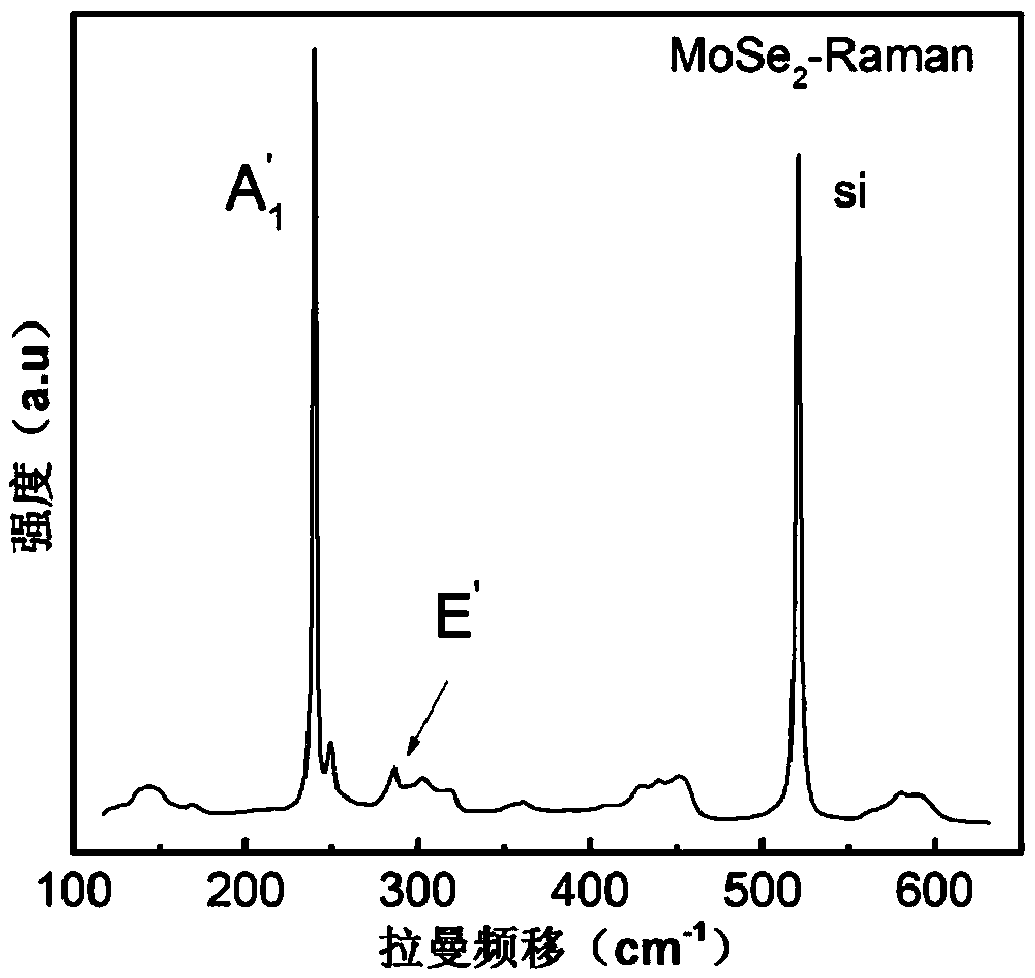

[0028] Embodiment 1 adopts Si / SiO 2 Synthesis of monolayer MoSe as a substrate 2 (1).

[0029] Synthesis of monolayer MoSe 2 The sample is made of molybdenum diselenide powder (99.9%), and the volume ratio of the gas is 95% inert gas Ar and 5% H 2 The mixed gas as carrier gas, with Si / SiO 2 Monolayer MoSe prepared by PVD method as substrate 2 . The only temperature zone of the high-temperature tube vacuum furnace is used not only as the area for melting and evaporating the molybdenum diselenide powder, but also as the area for the substrate to accept the sample deposition, so as to better control the temperature. The specific synthesis process is as follows: firstly, put quartz slices with length, width and height of 3cm, 2cm, and 1cm in a 10cm-long quartz boat, and then place Si / SiO 2×2×0.05cm 2 flakes and 0.1gMoSe 2The sample powder is placed on the quartz plate, while ensuring that the molybdenum diselenide powder is placed in front of the substrate, and finally they...

Embodiment 2

[0032] Embodiment 2 adopts Si / SiO 2 Synthesis of monolayer MoSe as a substrate 2 (2).

[0033] Si / SiO 2 As the substrate, monolayer MoSe was synthesized by PVD method 2 For the sample, when the synthesis process of Example 1 remains the same, the reaction conditions are set as follows: heating up to 960° C., holding time for 15 minutes, mixed gas flow rate of 25 sccm, and heating rate of 23° C. / min. Naturally cool to room temperature, and finally take out the quartz boat and the substrate for sample characterization. Si / SiO 2 MoSe prepared as substrate 2 The optical image of the monolayer sample is shown in Figure 5 As shown, it was found that there was a slight nodule phenomenon in the center of the sample, which was mainly caused by a slightly higher set temperature.

Embodiment 3

[0034] Example 3 is used as a comparative example. When the set temperature is higher than 970° C., a thick layer appears and the shape is irregular.

[0035] Si / SiO 2 As the substrate, monolayer MoSe was synthesized by PVD method 2 For the sample, when the synthesis process of Example 1 remains the same, the reaction conditions are set to be heated to 970° C., holding time is 15 minutes, mixed gas flow rate is 25 sccm, and the heating rate is 23° C. / min. Naturally cool to room temperature, and finally take out the quartz boat and the substrate for sample characterization. Si / SiO 2 MoSe prepared as substrate 2 The optical image of the monolayer sample is shown in Figure 6 As shown, it is found that the growth of the second layer begins on some monolayer samples, indicating that the high temperature may destroy the epitaxial growth of the monolayer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com