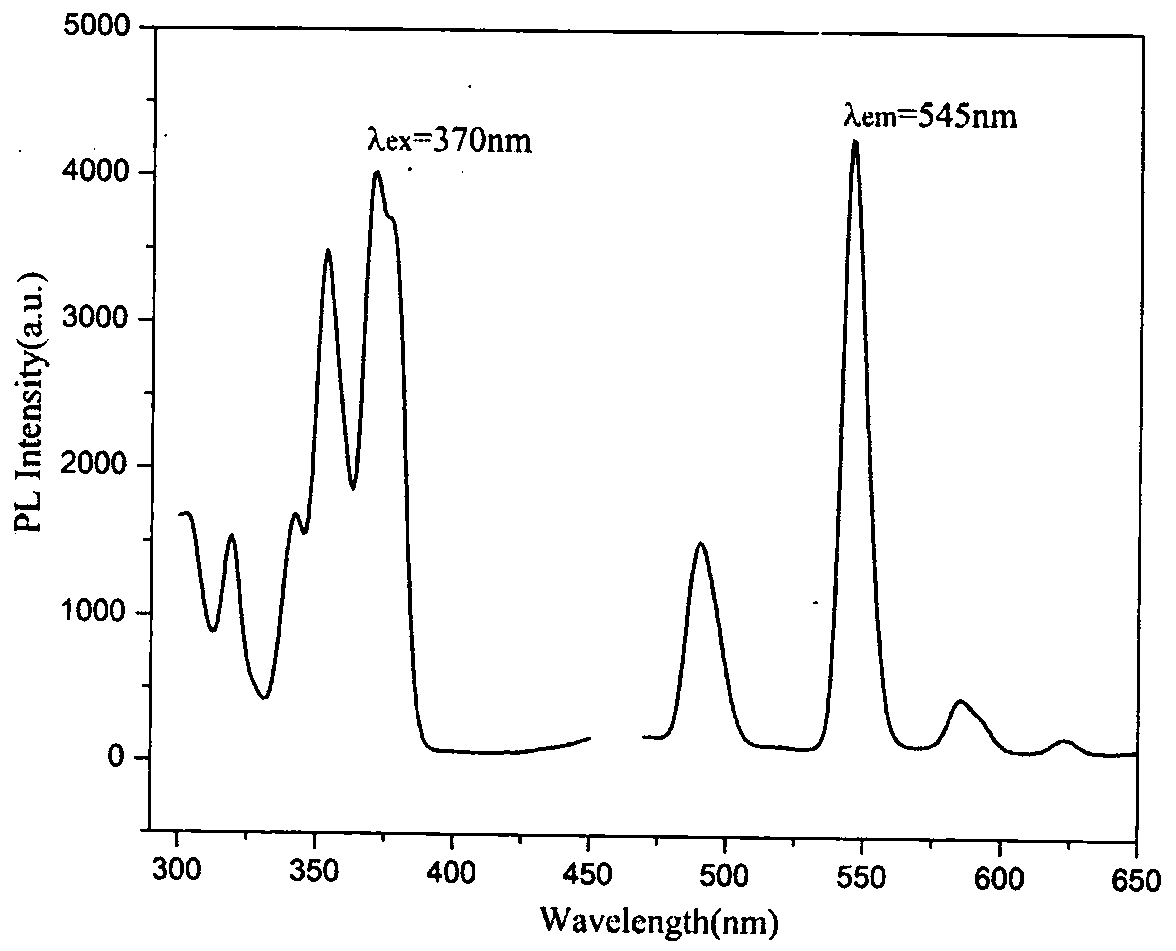

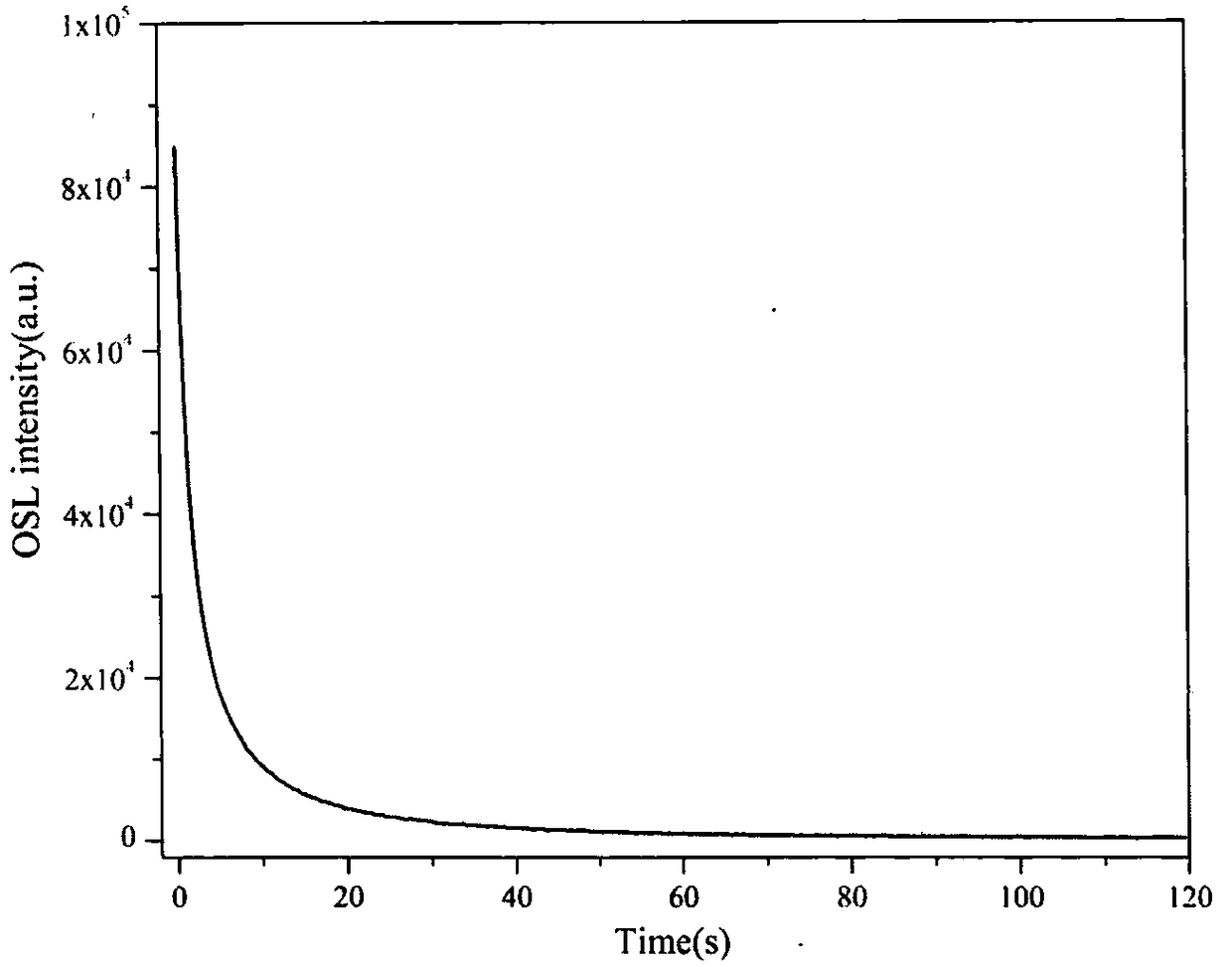

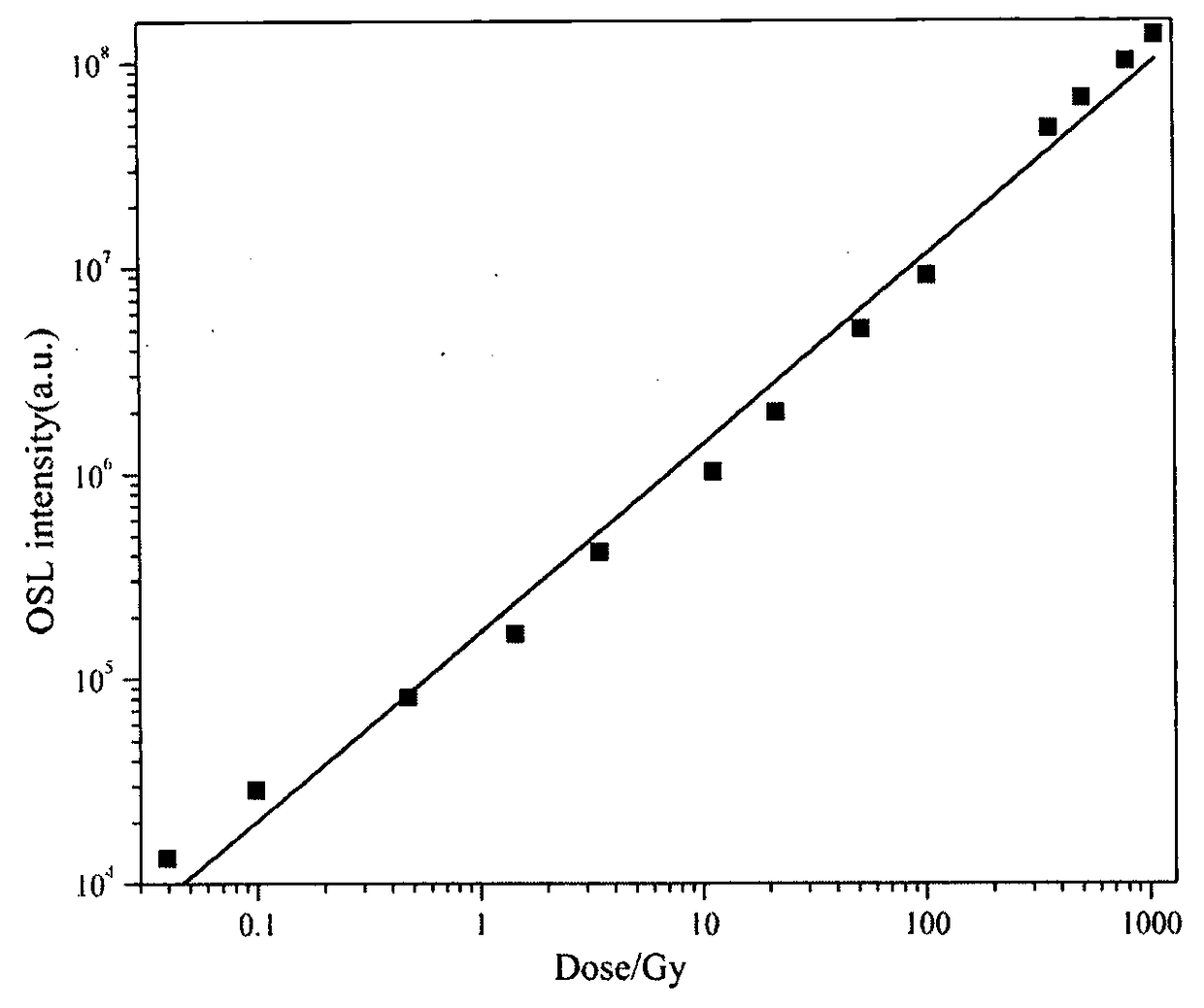

Terbium-doped calcium sodium phosphate glass ceramic photostimulated luminescence material and preparation method thereof

A light-excited luminescence, sodium calcium phosphate technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of unstable OSL performance, increased production cost, harsh C crystal growth conditions, etc., and achieve excellent physical and Chemical properties, ease of production, good dose-response linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. According to the general formula of terbium-doped sodium calcium phosphate glass ceramic material 25Na 2 O-23CaO-6P 2 o 5 -44B 2 o 3 -2ZrO 2 -xTb 4 o 7 , in the formula: x=0.1-1, accurately weigh raw material sodium carbonate 13.25g (0.125mol), calcium carbonate 11.5g (0.115mol), ammonium dihydrogen phosphate 6.9g (0.06mol), boron oxide 15.3168 with precision analytical balance g (0.22mol), 1.2322g (0.01mol) of zirconia, and 0.3739g (0.0005mol) of terbium oxide, put them in an agate mortar and grind them fully for about 6 hours to obtain a mixed material;

[0025] b. Put the mixed material obtained in step a into a corundum crucible, put it into a high-temperature tube furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min, keep it warm for 60min, and then raise the temperature to 1250°C at a rate of 2°C / min ℃, keep warm for 100min, and sinter at constant temperature to obtain molten glass;

[0026] c. Pour the molten glass obtaine...

Embodiment 2

[0031] a. According to the general formula 25Na of terbium-doped sodium calcium phosphate glass ceramic material 2 O-23CaO-6P 2 o 5 -44B 2 o 3 -2ZrO 2 -xTb 4 o 7 , in the formula: x=0.1-1, accurately weigh raw material sodium carbonate 13.25g (0.125mol), calcium carbonate 11.5g (0.115mol), ammonium dihydrogen phosphate 6.9g (0.06mol), boron oxide 15.3168 with precision analytical balance g (0.22mol), 1.2322g (0.01mol) of zirconia, and 0.9347g (0.00125mol) of terbium oxide, put them into an agate mortar and grind them fully for about 6 hours to obtain a mixed material;

[0032] b. Put the obtained mixed material into a corundum crucible, put it into a high-temperature tube furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min and keep it for 60 minutes, and then raise the temperature to 1250°C at a rate of 2°C / min. Insulate for 100 minutes, sinter at a constant temperature to obtain molten glass;

[0033] c. Pour the molten glass obtained in...

Embodiment 3

[0038] a. According to the general formula 25Na of terbium-doped sodium calcium phosphate glass ceramic material 2 O-23CaO-6P 2 o 5 -44B 2 o 3 -2ZrO 2 -xTb 4 o 7 , in the formula: x=0.1-1, accurately weigh raw material sodium carbonate 13.25g (0.125mol), calcium carbonate 11.5g (0.115mol), ammonium dihydrogen phosphate 6.9g (0.06mol), boron oxide 15.3168 with precision analytical balance g (0.22mol), 1.2322g (0.01mol) of zirconia, and 1.8693g (0.0025mol) of terbium oxide were put into an agate mortar and ground for about 6 hours to obtain a mixed material;

[0039] b. Put the obtained mixture into a corundum crucible, put it into a high-temperature tube furnace, raise the temperature from room temperature to 500°C at a rate of 5°C / min, keep it warm for 60 minutes, and then raise the temperature to 1250°C at a rate of 2°C / min. Insulate for 100 minutes, sinter at a constant temperature to obtain molten glass;

[0040] c. Pour the molten glass obtained in step b into a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com