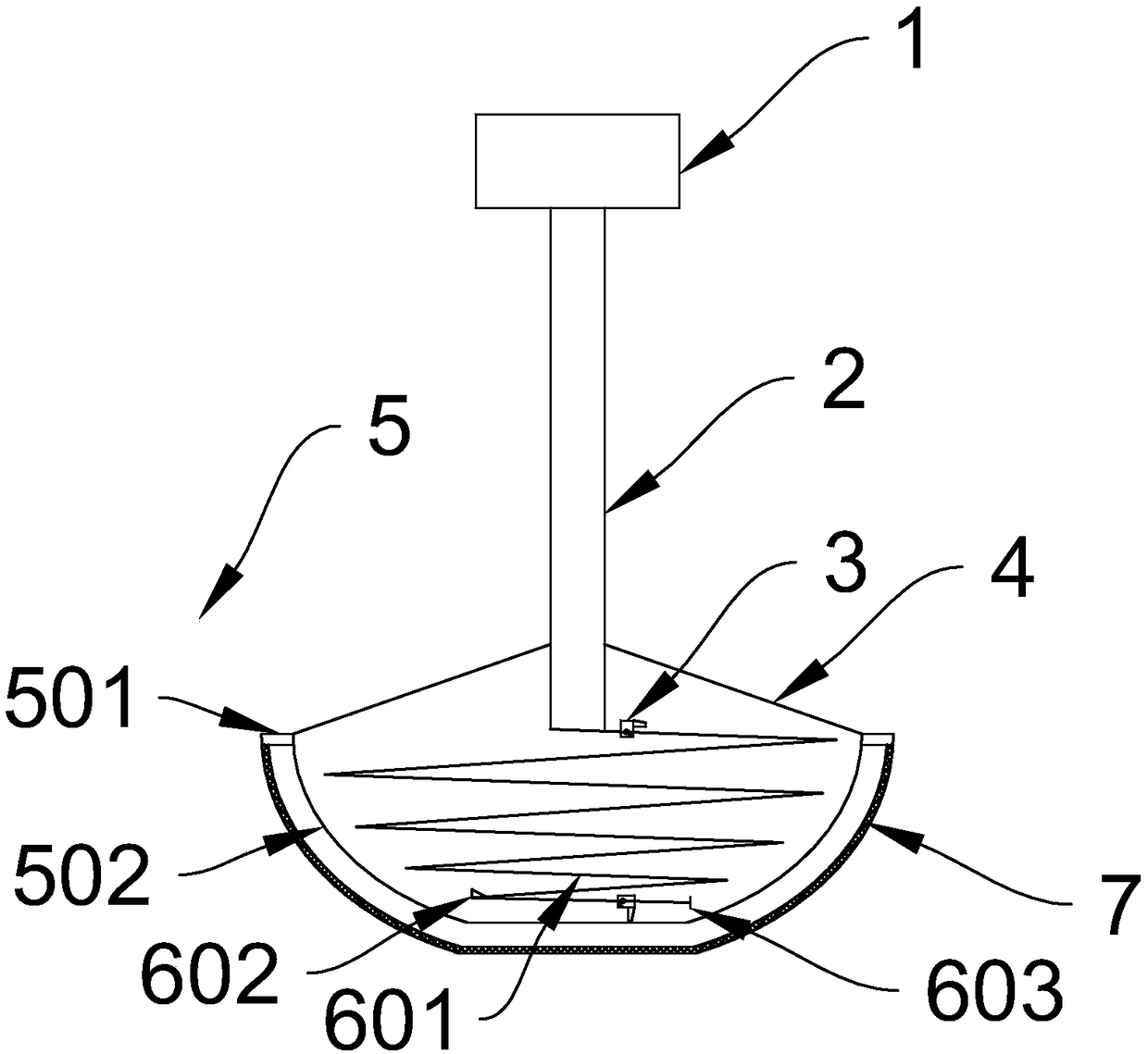

Imitation die-cast nonstick pan with deep opening structure

A non-stick pan, deep mouth technology, applied to the device, application, coating and other directions of coating liquid on the surface, can solve the problems of insufficient color and pattern, poor aesthetic effect, increase labor force, etc., and achieve rich pattern design. , the pattern effect is obvious, the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

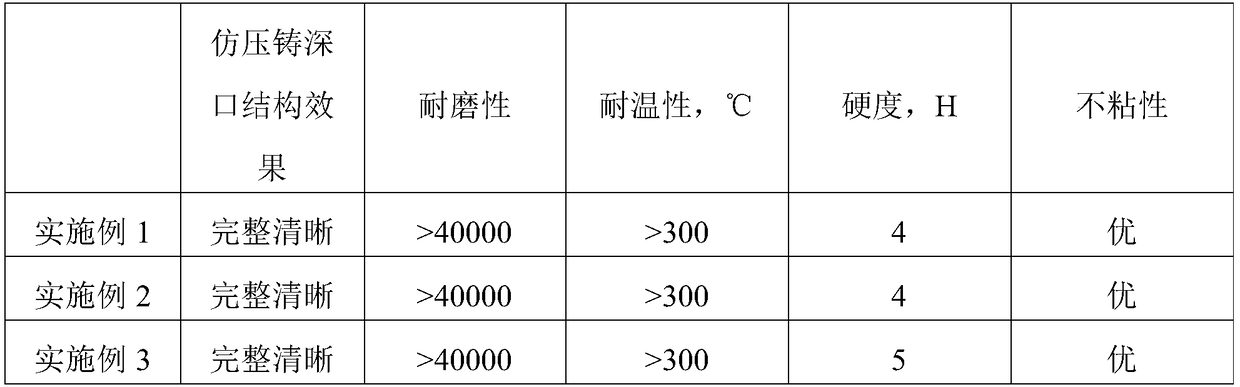

Embodiment 1

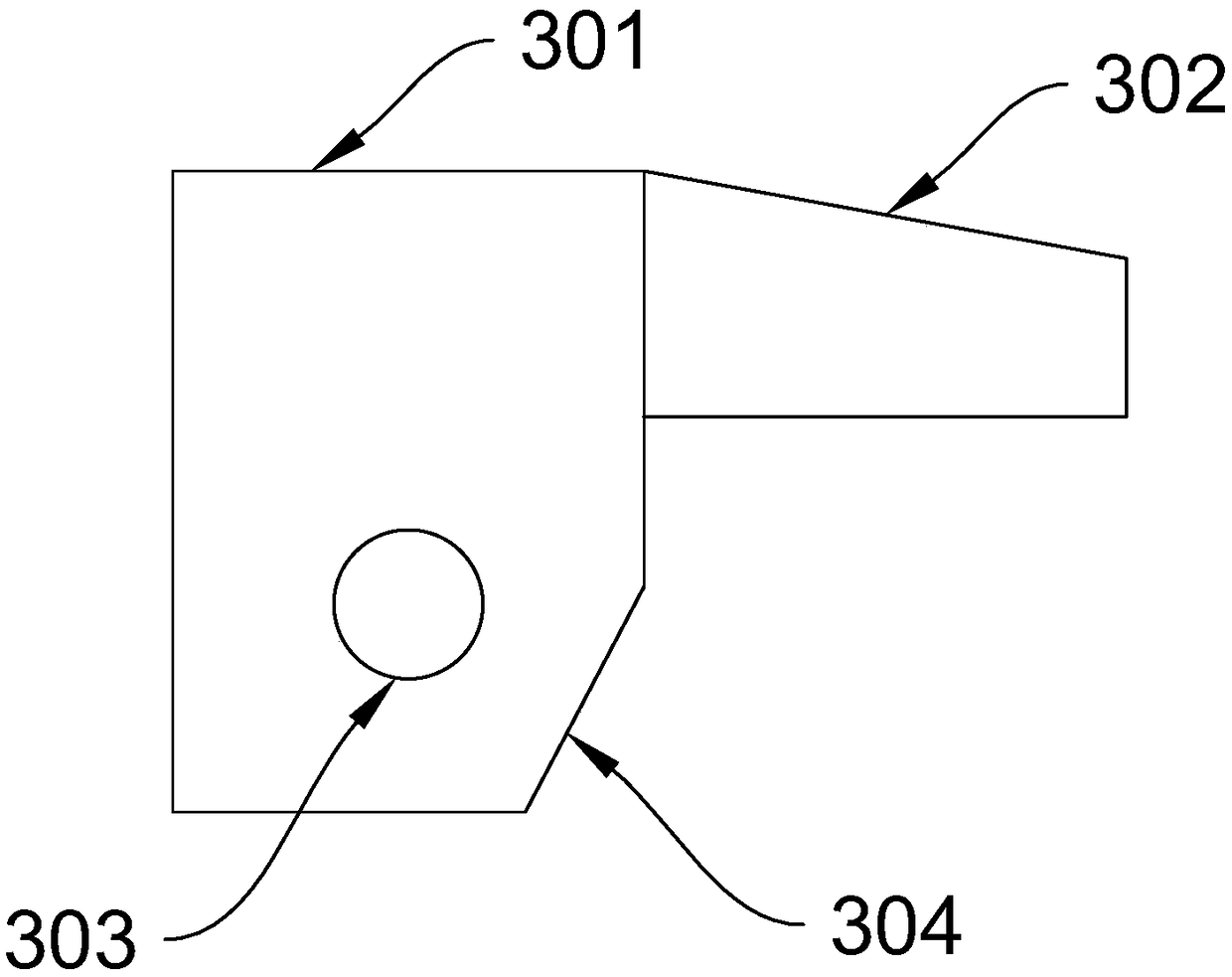

[0034] A non-stick pan with imitated die-casting deep mouth structure, comprising a pan body and an inner surface coating thereof, the inner surface coating includes a bottom layer and a surface layer imitating a die-casting deep mouth structure, and the surface layer consists of the following parts by weight Raw material composition: 10 parts of acrylic acid, 2 parts of polyethylene resin, 0.5 parts of zirconia, 2 parts of alumina, 1.5 parts of silicon dioxide, 2 parts of fatty amide polyoxyethylene ether, 30 parts of polytetrafluoroethylene resin, 10 parts of polyethylene Glycol, 20 parts deionized water, 5 parts sodium linear alkylbenzene sulfonate, 3 parts lauroyl glutamic acid, and 2 parts diacetyl monoglyceride of tartrate.

[0035] The preparation method of described surface layer, comprises the following steps:

[0036] S1: 10 parts of acrylic acid, 2 parts of polyethylene resin, 0.5 parts of zirconia, 2 parts of alumina, 1.5 parts of silica, 6 parts of deionized water...

Embodiment 2

[0053] A non-stick pan with imitated die-casting deep mouth structure, comprising a pan body and an inner surface coating thereof, the inner surface coating includes a bottom layer and a surface layer imitating a die-casting deep mouth structure, and the surface layer consists of the following parts by weight Raw material composition: 12 parts of acrylic acid, 2.5 parts of polyethylene resin, 1 part of zirconia, 3.5 parts of alumina, 1.8 parts of silicon dioxide, 2.5 parts of fatty amide polyoxyethylene ether, 35 parts of polytetrafluoroethylene resin, 15 parts of polyethylene Glycol, 23 parts deionized water, 6 parts sodium linear alkylbenzene sulfonate, 4 parts lauroyl glutamic acid, and 3 parts diacetyl monoglyceride of tartrate.

[0054] The preparation method of described surface layer, comprises the following steps:

[0055] S1: 12 parts of acrylic acid, 2.5 parts of polyethylene resin, 1 part of zirconia, 3.5 parts of alumina, 1.8 parts of silica, 7 parts of deionized w...

Embodiment 3

[0072] A non-stick pan with imitated die-casting deep mouth structure, comprising a pan body and an inner surface coating thereof, the inner surface coating includes a bottom layer and a surface layer imitating a die-casting deep mouth structure, and the surface layer consists of the following parts by weight Raw material composition: 15 parts of acrylic acid, 3 parts of polyethylene resin, 1.5 parts of zirconia, 5 parts of alumina, 2 parts of silicon dioxide, 3 parts of fatty amide polyoxyethylene ether, 40 parts of polytetrafluoroethylene resin, 20 parts of polyethylene Glycol, 25 parts deionized water, 8 parts sodium linear alkylbenzene sulfonate, 5 parts lauroyl glutamic acid, and 4 parts diacetyl monoglyceride of tartrate.

[0073] The preparation method of described surface layer, comprises the following steps:

[0074] S1: Mix 15 parts of acrylic acid, 3 parts of polyethylene resin, 1.5 parts of zirconia, 5 parts of alumina, 2 parts of silica, 8 parts of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com