Novel IGZO (indium gallium zinc oxide) etching liquid for panel display array process

An array manufacturing process and flat panel display technology, which is applied in the direction of surface etching composition, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low etching rate, easy residue, insufficient side engraving, etc., and achieve excellent etching accuracy, Good etching effect and high etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

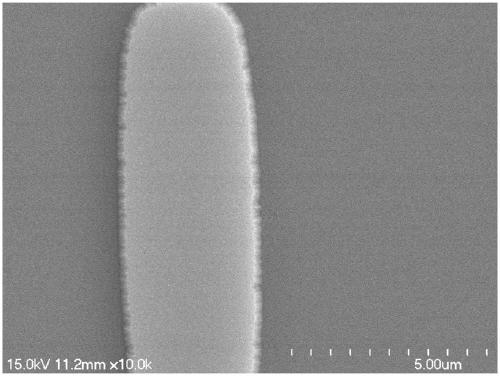

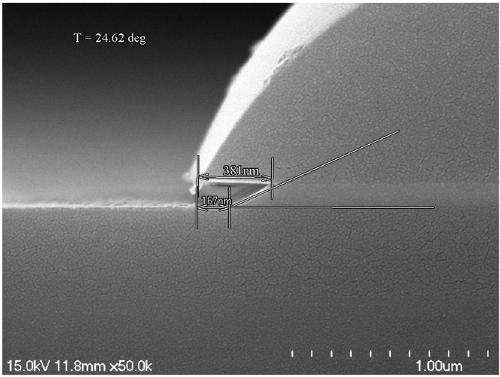

Image

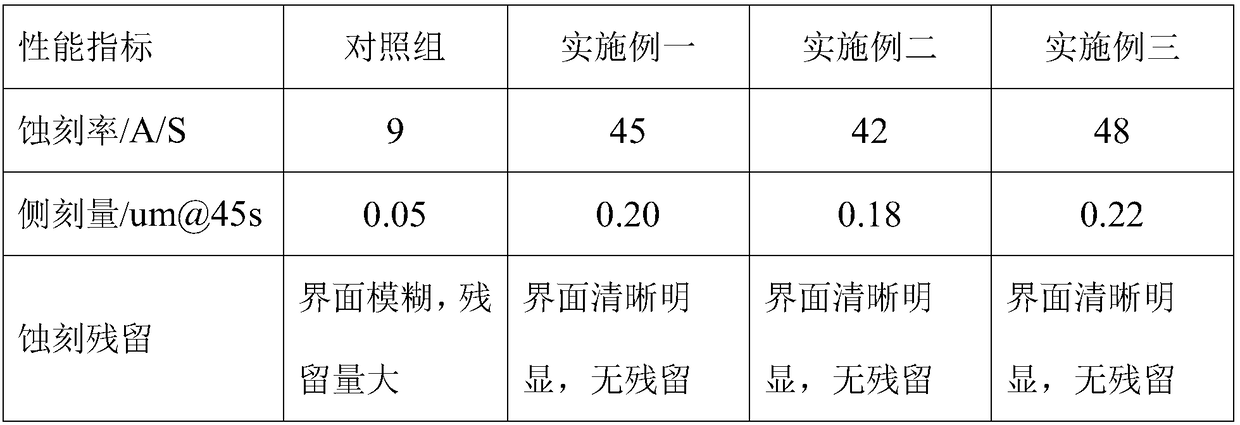

Examples

Embodiment 1

[0022] Ratio of each raw material:

[0023] Sulfuric acid 5%, nitric acid 2%, acetic acid 2%, fluoride 0.5%, butanol random polyether BPE1500 (surfactant) 500ppm and the balance ultrapure water.

[0024] Specific preparation method:

[0025] Under normal temperature and pressure, add the raw materials of the formula quantity into the mixing kettle in turn; mix to a uniform and stable aqueous solution; filter with a filter, and then fill it into the designated packaging container.

Embodiment 2

[0027] Ratio of each raw material:

[0028] Sulfuric acid 5%, nitric acid 5%, acetic acid 5%, fluoride 0.1%, isomeric decanol ether XP-70 (surfactant) 100ppm and the balance ultrapure water.

[0029] Specific preparation method:

[0030] Under normal temperature and pressure, add the raw materials of the formula quantity into the mixing kettle in turn; mix to a uniform and stable aqueous solution; filter with a filter, and then fill it into the designated packaging container.

Embodiment 3

[0032] Ratio of each raw material:

[0033] Sulfuric acid 10%, nitric acid 10%, acetic acid 10%, fluoride 0.1%, glycerol random polyether GPE3000 (surfactant) 900ppm and balance ultrapure water.

[0034] Specific preparation method:

[0035] Under normal temperature and pressure, add the raw materials of the formula quantity into the mixing kettle in turn; mix to a uniform and stable aqueous solution; filter with a filter, and then fill it into the designated packaging container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com