Thin-film solar cell and preparation method thereof

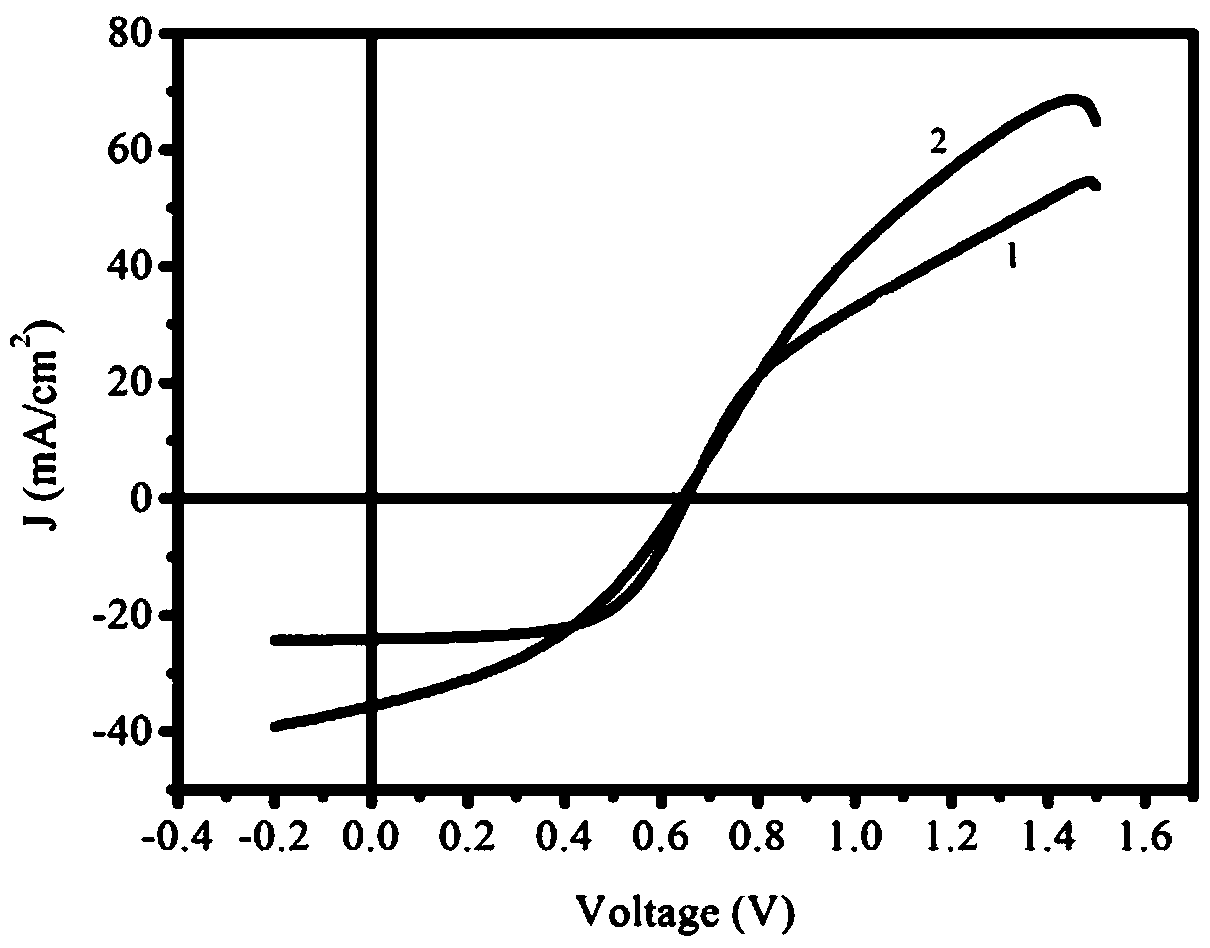

A technology of thin-film solar cells and transparent conductive films, applied in the field of solar cells, can solve the problems of low short-circuit current density of CdTe cells, and achieve the effects of suitable large-scale production, simple structure, and improvement of short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

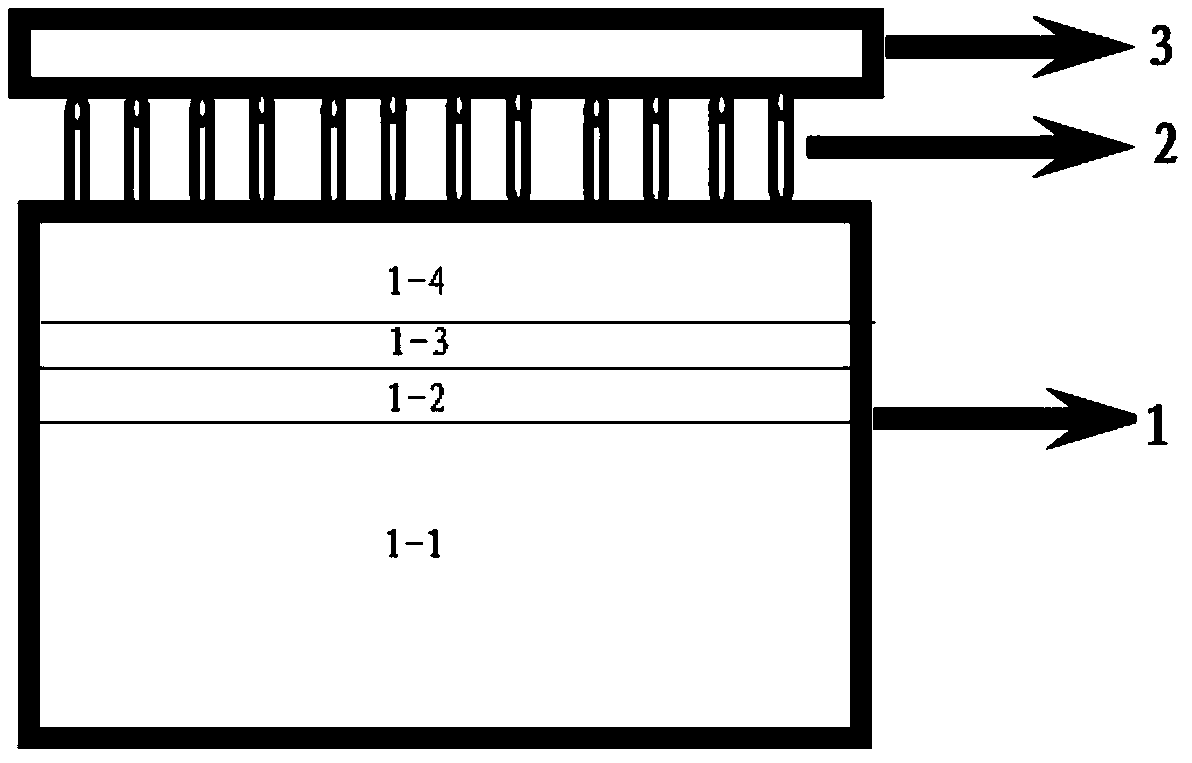

[0032] The present invention provides a method for preparing the thin film solar cell described in the above solution, which includes the following steps:

[0033] According to the structure of the thin film solar cell, a transparent conductive film, a window layer, a CdTe optical absorption layer, a quantum dot buffer layer and a conductive back electrode are sequentially prepared on a substrate.

[0034] The invention prepares a transparent conductive film on a substrate to obtain a transparent conductive film / substrate structure. In the present invention, the method for preparing the transparent conductive film on the substrate preferably includes a sol-gel method, a magnetron sputtering method or a chemical vapor deposition method.

[0035] In the present invention, the preparation parameters of the transparent conductive film prepared by the sol-gel method are not particularly limited, and preparation parameters well known to those skilled in the art may be used. In the embodim...

Embodiment 1

[0057] Using rigid glass as substrate, SnO is prepared on rigid glass by sol-gel method 2 : F(FTO) film, get SnO 2 :F(FTO) film / rigid glass structure; among them, SnO 2 : The preparation method of F(FTO) film is: take 50mLSnCl 2 And 50mLH 2 Dissolve O in 50mL of absolute ethanol, reflux at 80℃ for 4h, slowly add a mixture of water and ethanol in a 1:1 volume ratio; reflux at 80℃ for 3h, adjust the pH to 3; add 50mL formamide, add 50mLNH 4 F water solution, the prepared solution is allowed to stand for 24 hours; fix the cleaned substrate on the film spinning machine, spin the film at a speed of 2000r / min; then dry it in a vacuum drying oven at 100°C for 30 minutes, and then put it in the muffle In the furnace, slowly raise the temperature to 300°C and keep the temperature constant for 10 minutes; repeat the above film spinning process 4 times; finally treat at 600°C for 20 minutes; the SnO 2 : The thickness of the F(FTO) film is 200nm.

[0058] Using pulsed laser deposition method i...

Embodiment 2

[0064] Using flexible mica as the substrate material, ZnO:Al(AZO) film is prepared on flexible mica by magnetron sputtering method to obtain ZnO:Al(AZO) film / flexible mica structure; among them, ZnO:Al(AZO) film The preparation parameters are: the temperature of the flexible mica substrate is room temperature, the target base distance is 8cm, the carrier gas is argon, the pressure is 0.1Pa, and the sputtering power density is 2.78W / cm 2 The thickness of the ZnO: Al (AZO) film is 350 nm.

[0065] The CdS:O window layer was prepared on the ZnO:Al(AZO) film / flexible mica structure by magnetron sputtering, and the CdS:O window layer / ZnO:Al(AZO) film / flexible mica structure was obtained; among them, CdS:O The preparation parameters of the window layer are: ZnO:Al(AZO) film / flexible mica structure temperature is room temperature, target base distance is 13cm, carrier gas is argon / oxygen with a volume ratio of 56:1, pressure is 3Pa, sputtering The power density is 1.19W / cm 2 The thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com