Nitrogen-doped carbon composite SnFe2O4 lithium ion battery negative electrode material as well as preparation method and application thereof

A lithium-ion battery, nitrogen-doped carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of specific capacity, cycle stability decline, loss of first cycle charge and discharge capacity, material specific capacity decline, etc. Achieve the effect of good electrochemical reversibility, low production cost and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A nitrogen-doped carbon-composite SnFe 2 o 4 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0033] 1) Add the iron source and the tin source to the Tween-20 aqueous solution at the same time, stir and mix well, then add the alkali solution, fully react, separate and collect the precipitate, and obtain SnFe 2 o 4 nanoparticles;

[0034] 2) SnFe 2 o 4 Nanoparticles and dopamine hydrochloride were added to the Tris-HCl buffer, fully reacted, and then centrifuged to collect the solid product to obtain the precursor;

[0035] 3) The precursor is placed in an inert atmosphere and calcined to obtain a nitrogen-doped carbon-composite SnFe 2 o 4 Lithium-ion battery anode materials (SnFe 2 o 4 @NC).

[0036] Preferably, the molar ratio of Fe and Sn in step 1) is 1:0.5.

[0037] Preferably, the concentration of the iron source in step 1) in the Tween-20 aqueous solution is 0.02-0.5 mol / L.

[0038]Preferably, ...

Embodiment 1

[0051] A nitrogen-doped carbon-composite SnFe 2 o 4 Lithium-ion battery anode materials (SnFe 2 o 4 @NC) preparation method, comprises the following steps:

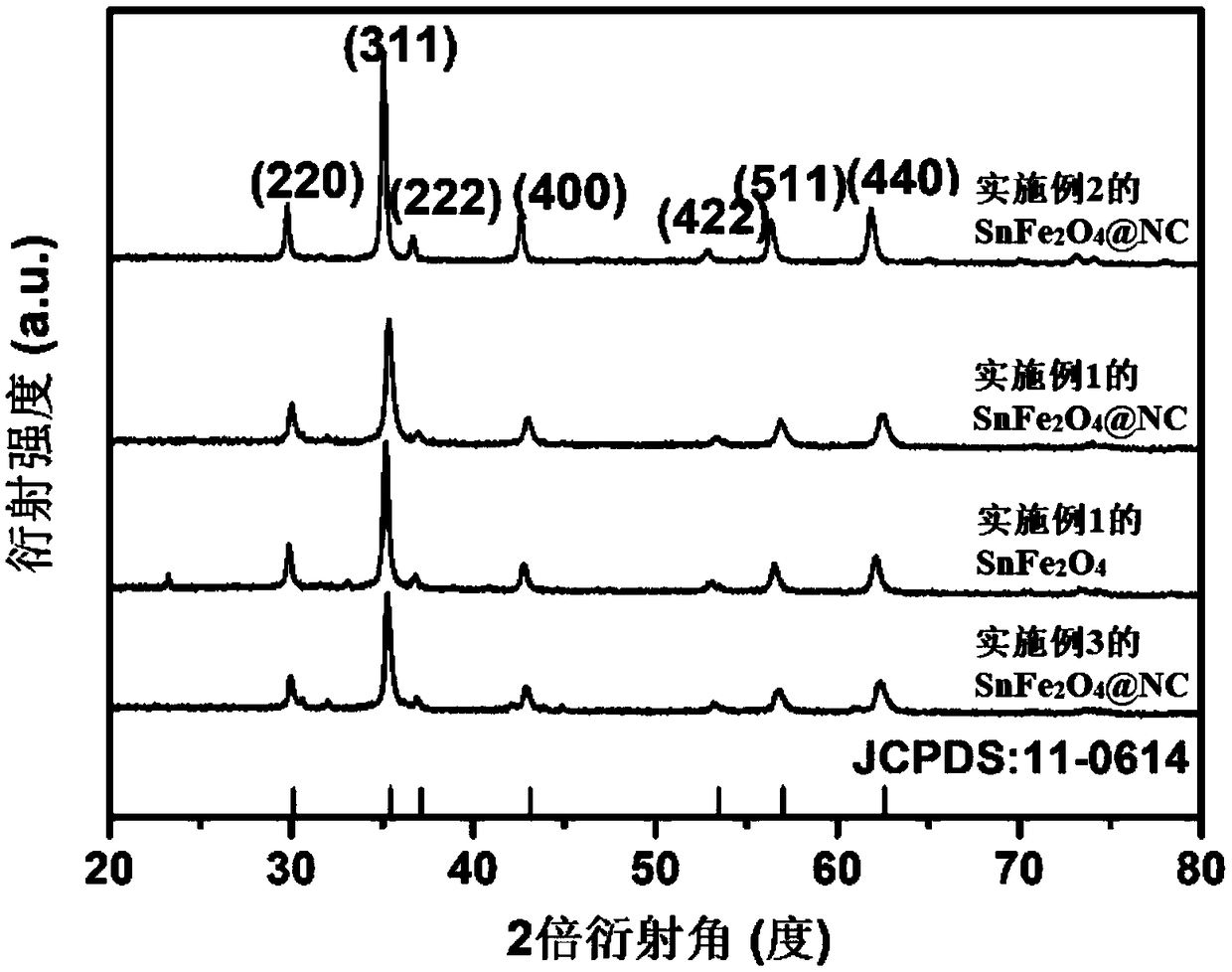

[0052] 1) 12mmol of FeCl 2 4H 2 O and 6 mmol of SnCl 2 2H 2 O was simultaneously added to 150 mL of Tween-20 aqueous solution (prepared by Tween-20 and distilled water according to the volume ratio of 1:10), fully stirred and mixed, and then added NaOH solution with a concentration of 4mol / L to the reaction solution. pH value>10, stirred at 80°C for 3h, separated and collected the precipitate, washed the precipitate with distilled water several times, dried at 60°C for 10h, and obtained SnFe 2 o 4 Nanoparticles (XRD pattern as shown in figure 1 shown);

[0053] 2) SnFe with a mass ratio of 1:0.3 2 o 4 Nanoparticles and dopamine hydrochloride were added to Tris-HCl buffer solution (pH=8.5) with a concentration of 10 mmol / L, stirred at 80°C for 4h, and the solid product was collected by centrifugation, washed wi...

Embodiment 2

[0064] A nitrogen-doped carbon-composite SnFe 2 o 4 Lithium-ion battery anode materials (SnFe 2 o 4 @NC) preparation method, comprises the following steps:

[0065] 1) 15mmol of Fe(NO 3 ) 3 9H 2 O and 7.5 mmol of SnCl 2 2H 2 O was added to 150mL Tween-20 aqueous solution (prepared by Tween-20 and distilled water according to the volume ratio of 1:25) at the same time, fully stirred and mixed, and then added NaOH solution with a concentration of 4mol / L to the reaction solution. pH value>10, stirred at 25°C for 4h, separated and collected the precipitate, washed the precipitate with distilled water several times, dried at 80°C for 6h, and obtained SnFe 2 o 4 nanoparticles;

[0066] 2) SnFe with a mass ratio of 1:0.1 2 o 4 Nanoparticles and dopamine hydrochloride were added to Tris-HCl buffer (pH=8.5) with a concentration of 10mmol / L, stirred at 25°C for 6h, and the solid product was collected by centrifugation, washed with distilled water several times, and dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com