Automatic die-pressing production line for purification tank shell

A production line and purification tank technology, applied in lamination, layered products, lamination devices, etc., can solve the problems of inability to meet environmental protection and occupational labor hygiene, damage workers' health, and low degree of automation, and achieve changes in workers' operations. The environment and processing quality are reliable and consistent, and the effect of reducing the repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An automatic molding production line for a septic tank shell of the present invention will be described in detail below with reference to the accompanying drawings.

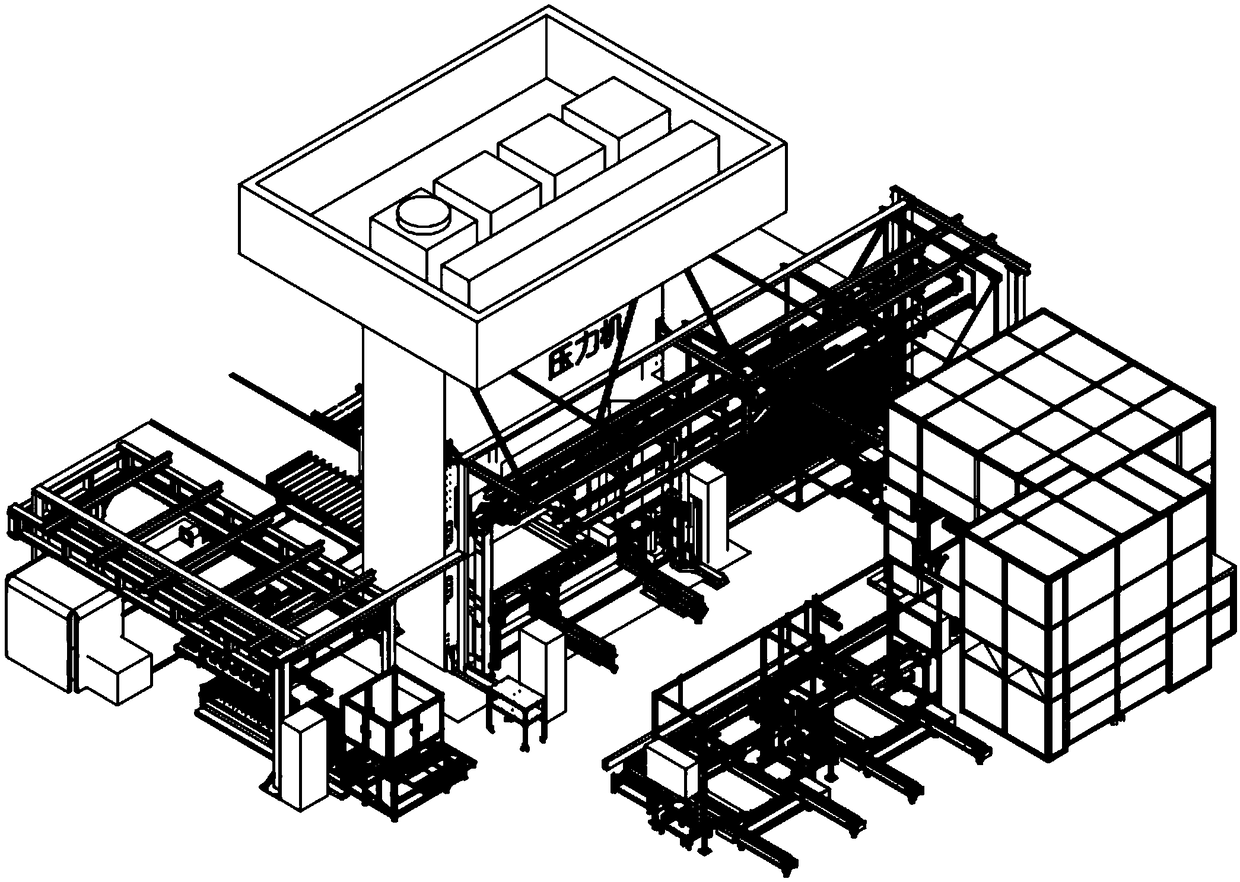

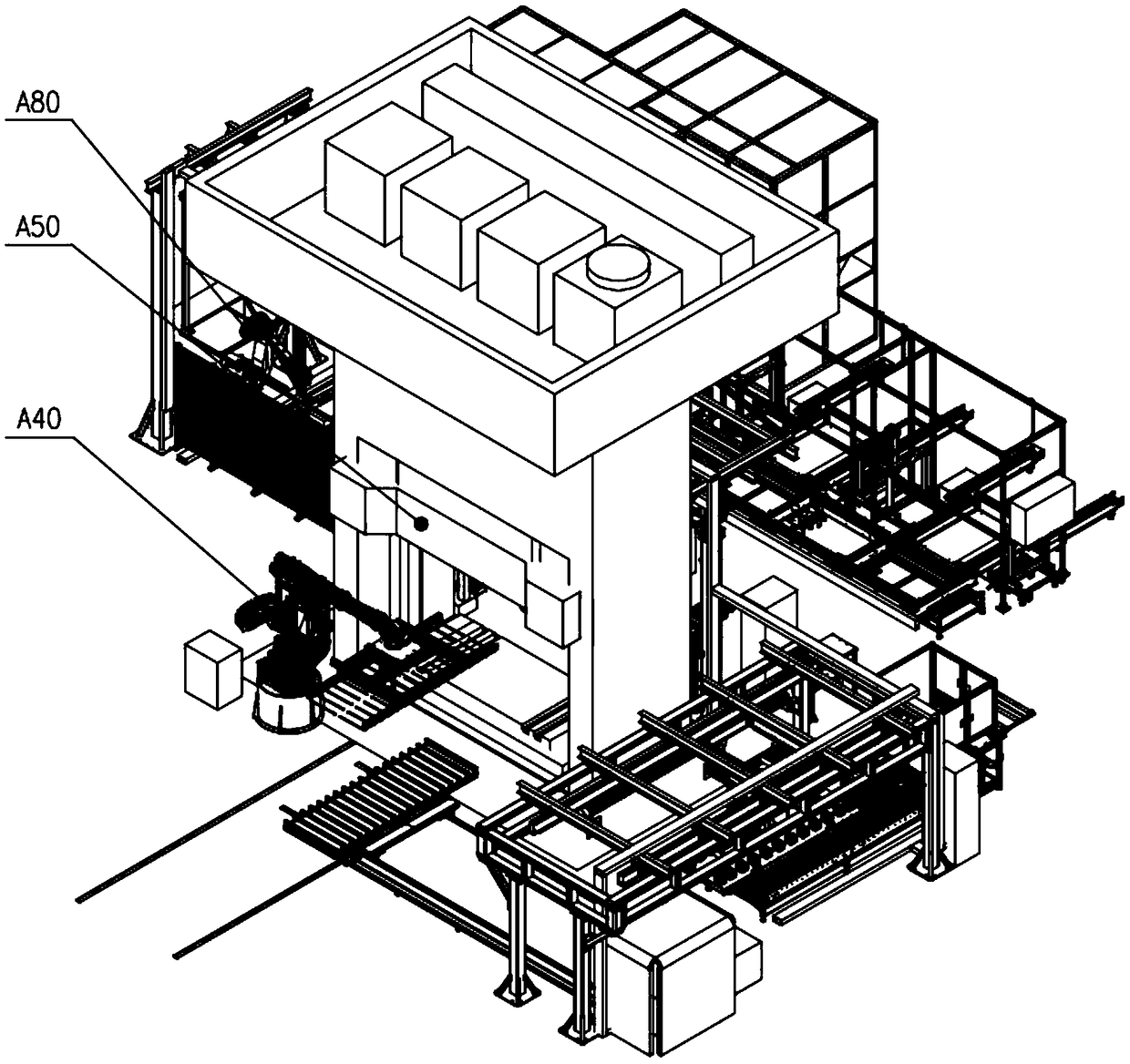

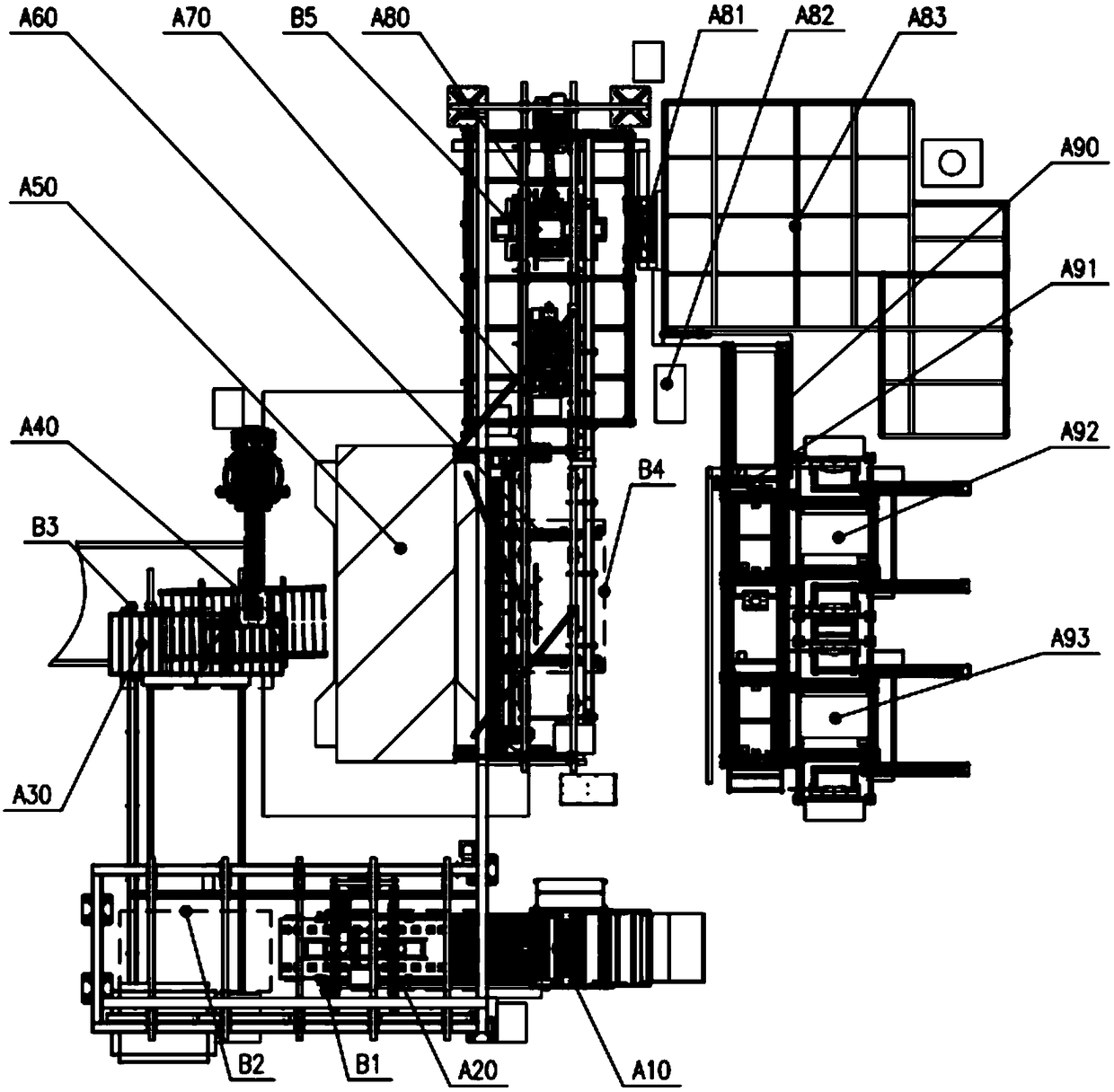

[0034] Such as figure 1 , figure 2 , image 3 As shown, a kind of purification tank shell automatic molding production line of the present invention, its structure comprises SMC sheet material uncovering and shearing station A10, SMC sheet material absorption transfer station A20, SMC sheet material stacking and weighing transfer station A30 , robot loading station A40, press (including mold) A50, shell end output station A60, shell transfer inspection station A70, robot grinding and countersunk hole A80, master control system A82, laser drilling equipment A83 , laser marking station A91, qualified product stacking and off-line A92, unqualified product stacking and off-line A93, the SMC sheet peeling and shearing station A10 is located at the starting end of the molding production line and the belt diap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap