A method for improving water resistance or solvent resistance of waterborne polyurethane

A technology of water-based polyurethane and solvent resistance, which is applied in the field of improving the water resistance or solvent resistance of water-based polyurethane, which can solve the problems of limited water resistance, complicated operation, high cost, etc., and achieves improved water/solvent resistance, simple preparation process, and mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

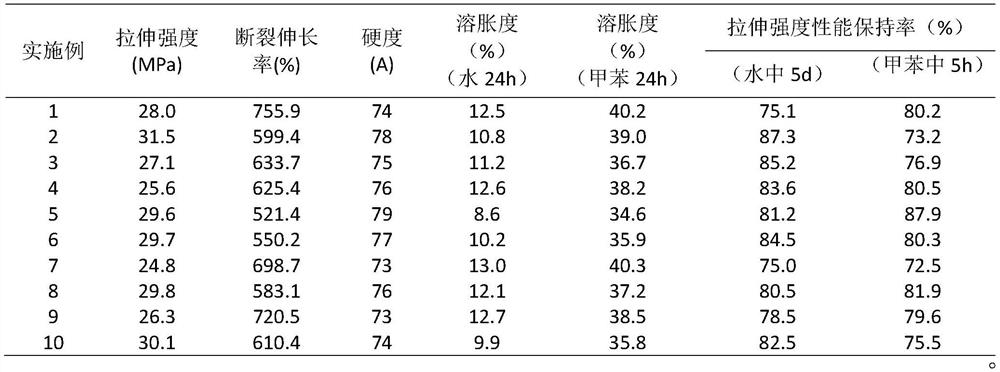

Embodiment 1

[0048] 1) Add 100 parts by mass of 1,4-butanediglycidyl ether and 15 parts by mass of the catalyst basic exchange resin D296 into the autoclave, raise the temperature to 140°C and pass in CO 2 , the pressure was kept at 2MPa, and the catalyst was filtered after reacting for 30h to obtain a cyclocarbonate compound. Then weigh 100 parts of the synthesized cyclic carbonate compound, add 82.8 parts of ethylenediamine and heat it to 100°C for 6 hours of heat preservation reaction. After the reaction, vacuum and vacuum distillation at 90°C for 5 hours to remove excess ethylenediamine to obtain alcohol amine expanded chain agent.

[0049] 2) the poly(ethylene adipate propylene glycol) polyol (M n =2000) into the reactor, heated up to 140°C, vacuum dehydrated for 2 hours; then cooled to 50°C, added 1.5 parts of 2,2-hydroxymethyl propionic acid and 4.61 parts of isophorone diisocyanate compound, and then heated React at 75°C for 2 hours; after the reaction, cool down to 50°C and add ...

Embodiment 2

[0054] 1) Add 100 parts by mass of diethylene glycol diglycidyl ether and 5 parts by mass of the catalyst basic exchange resin D296 into the autoclave, heat up to 140°C and feed CO 2 , the pressure was kept at 4MPa, and the catalyst was filtered after reacting for 45h to obtain a cyclocarbonate compound. Then weigh 100 parts of the synthesized cyclic carbonate compound, add 120.1 parts of hexamethylenediamine and heat it to 70°C for 10 hours of heat preservation reaction. chain agent.

[0055] 2) the polycarbonate diol (M n =2000) into the reactor, heated up to 100°C, vacuum dehydrated for 4h; then cooled to 50°C, added 0.75 parts of 2,2-hydroxymethyl propionic acid and 3.04 parts of hexamethylene diisocyanate compound, and then heated React at 90°C for 2 hours; after the reaction, cool down to 60°C and add 0.24 parts of 1,4-butanediol and 10.52 parts of solvent N-methylpyrrolidone for reflux reaction for 2 hours.

[0056] 3) Cool the reaction system to 25°C, add 1.04 parts...

Embodiment 3

[0060] 1) Add 100 parts by mass of ethylene glycol diglycidyl ether and 15 parts by mass of the catalyst basic exchange resin D296 into the autoclave, heat up to 130°C and feed CO 2 , the pressure was kept at 2MPa, and the catalyst was filtered after reacting for 30h to obtain a cyclocarbonate compound. Then weigh 100 parts of the synthesized cyclic carbonate compound, add 52.4 parts of hexamethylenediamine and heat it to 70°C for 10 hours of heat preservation reaction. chain agent.

[0061] 2) the polycarbonate diol (M n =1000) into the reactor, heated up to 120°C, vacuum dehydration for 3h; after cooling down to 50°C, add 1 part of 2,2-hydroxymethylpropionic acid, 2.26 parts of diphenylmethane diisocyanate and 2.01 parts of isocyanate For phorone diisocyanate, heat up to 90°C for 2 hours; after the reaction, cool down to 60°C and add 0.3 parts of 1,4-butanediol and 6.70 parts of solvent acetone to reflux for 2 hours.

[0062] 3) Cool the reaction system to 25°C, add 1.39 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com