A kind of anti-cracking computer heat-conducting silicone grease and preparation method thereof

A heat-conducting silicone grease and computer technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems affecting the overall performance and service life of the computer, the reduction of thermal conductivity, troublesome hands-on ability, etc., to achieve good performance and improve heat conduction The effect of performance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

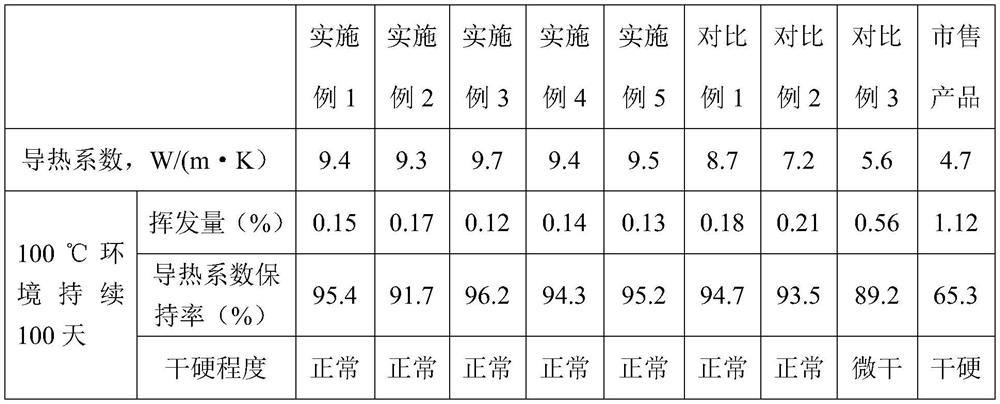

Examples

Embodiment 1

[0021] An anti-cracking computer heat-conducting silicone grease, including the following raw materials in parts by weight: 30 parts of methyl silicone oil, 2 parts of vinyltrimethoxysilane, 3 parts of octylphenol polyoxyethylene ether, 6 parts of aluminum oxide, zinc oxide 4 parts, 3 parts of graphene, 4 parts of nano-silver, 5 parts of diamond powder, 1 part of ethylene glycol distearate, 2 parts of coupling agent, 2 parts of di(hydrogenated tallow) phthalic acid amide, 1 part of disodium diamine tetraacetate, 30 parts of absolute ethanol.

[0022] Wherein, the coupling agent is silane coupling agent KH560.

[0023] Wherein, the particle size of the diamond micropowder is not greater than 5 μm.

[0024] In this embodiment, the preparation method of the anti-cracking computer thermal grease, the steps are as follows:

[0025] 1) Mix vinyltrimethoxysilane, octylphenol polyoxyethylene ether, aluminum oxide, zinc oxide, graphene, ethylene glycol distearate, coupling agent, and...

Embodiment 2

[0030] A kind of anti-cracking computer heat-conducting silicone grease, including the following raw materials in parts by weight: 35 parts of methyl silicone oil, 3 parts of vinyltrimethoxysilane, 4 parts of octylphenol polyoxyethylene ether, 8 parts of aluminum oxide, zinc oxide 5 parts, 4 parts of graphene, 5 parts of nano-silver, 6 parts of diamond powder, 1.8 parts of ethylene glycol distearate, 4 parts of coupling agent, 5 parts of di(hydrogenated tallow) phthalic acid amide, 1.8 parts of disodium diamine tetraacetate, 45 parts of absolute ethanol.

[0031] Wherein, the coupling agent is silane coupling agent KH560.

[0032] Wherein, the particle size of the diamond micropowder is not greater than 5 μm.

[0033] In this embodiment, the preparation method of the anti-cracking computer thermal grease, the steps are as follows:

[0034] 1) Mix vinyltrimethoxysilane, octylphenol polyoxyethylene ether, aluminum oxide, zinc oxide, graphene, ethylene glycol distearate, coupli...

Embodiment 3

[0039] An anti-cracking computer heat-conducting silicone grease, comprising the following raw materials in parts by weight: 40 parts of methyl silicone oil, 4 parts of vinyltrimethoxysilane, 5 parts of octylphenol polyoxyethylene ether, 9 parts of aluminum oxide, zinc oxide 6 parts, 4.5 parts of graphene, 6 parts of nano-silver, 7 parts of diamond powder, 1.5 parts of ethylene glycol distearate, 3.5 parts of coupling agent, 3.5 parts of di(hydrogenated tallow base) phthalic acid amide, 1.5 parts of disodium diamine tetraacetate, 40 parts of absolute ethanol.

[0040] Wherein, the coupling agent is silane coupling agent KH560.

[0041] Wherein, the particle size of the diamond micropowder is not greater than 5 μm.

[0042] In this embodiment, the preparation method of the anti-cracking computer thermal grease, the steps are as follows:

[0043] 1) Mix vinyltrimethoxysilane, octylphenol polyoxyethylene ether, aluminum oxide, zinc oxide, graphene, ethylene glycol distearate, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com