Synthesizing method of iodine-lead perovskite quantum dot

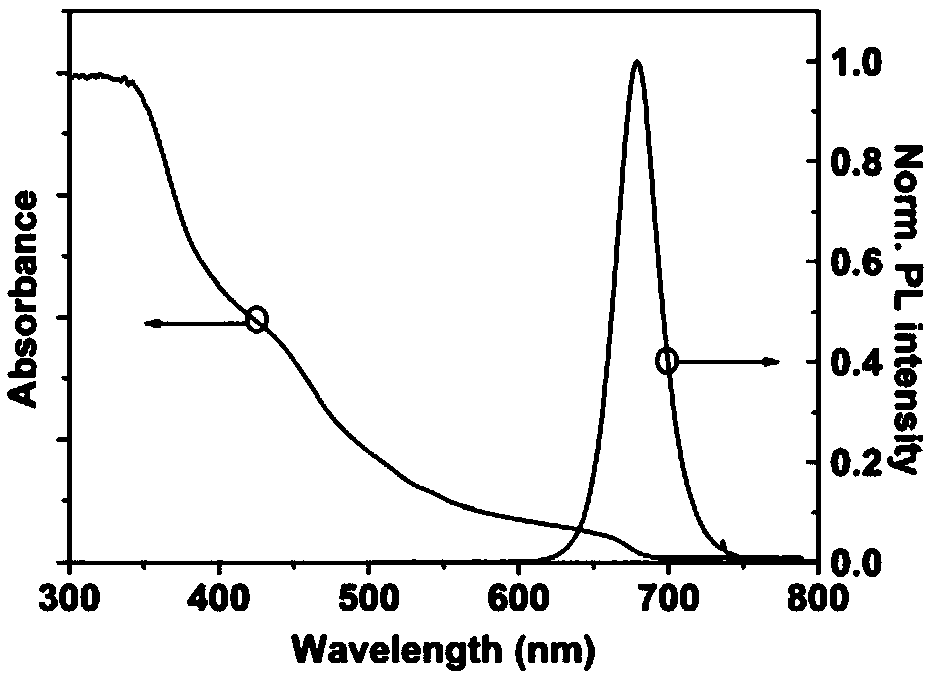

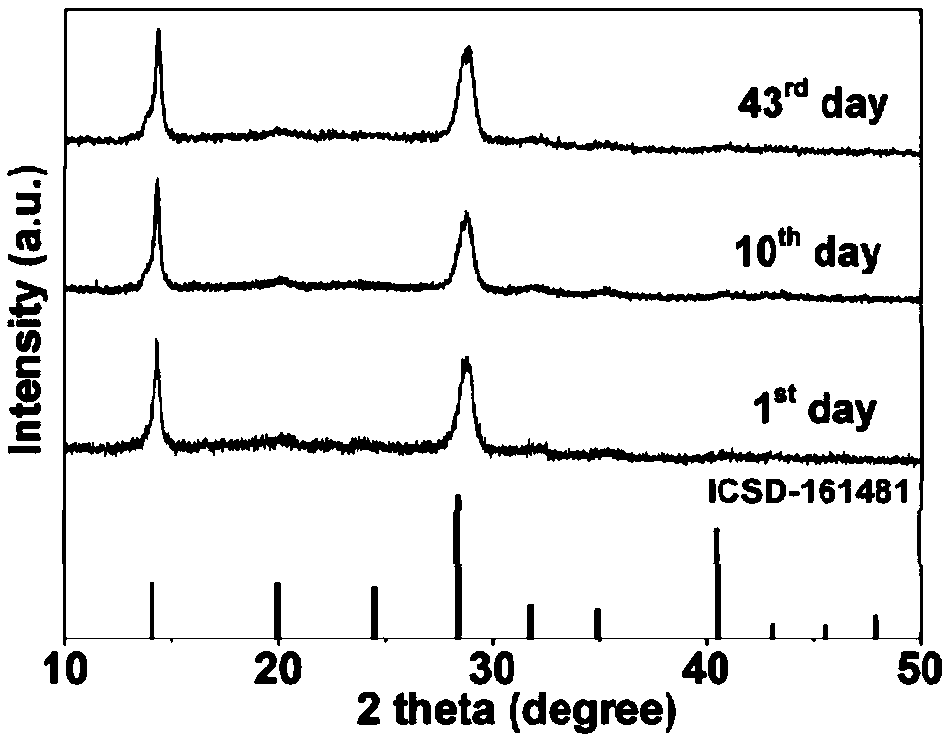

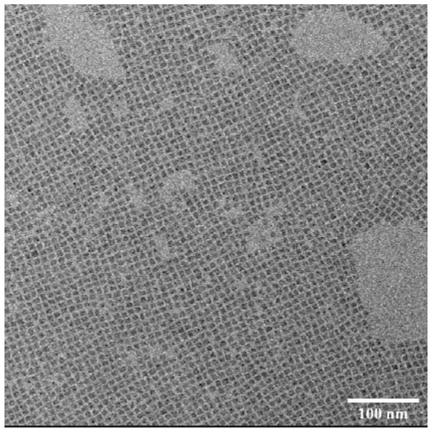

A technology of lead-iodine perovskite and synthesis method, applied in chemical instruments and methods, preparation of amino compounds from amines, nanotechnology, etc., to achieve high fluorescence quantum efficiency, simple operation, and easy large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Will Cs 2 CO 3 (analytical pure) and oleic acid (analytical pure) were mixed according to the stoichiometric ratio of 1:3, then 5 mL of octadecene (analytical pure) was added, nitrogen gas was introduced, and the mixture was heated to 120 ° C until the powder was completely dissolved and then cooled to room temperature. The concentration of Cs ions in the resulting solution was 5.0 mol / 42.5 mL. Mix PbO (analytical pure) and oleic acid in a stoichiometric ratio of 1:3, then add 5 mL of octadecene, blow in nitrogen, heat the mixture to 120 °C, and cool to room temperature until the powder is completely dissolved. The concentration of Pb ions in the obtained solution was 1.0 mol / L. After the above two solutions were preheated at 80°C, 0.4mL and 0.5mL were mixed with 0.4mL oleylamine and 5mL octadecene respectively, and the mixture was heated to 150°C, followed by rapid injection of 0.2mL iodotrimethylsilane, and the reaction After 5s, cool the device with an ice-water b...

Embodiment 2

[0024] Will Cs 2 CO 3 (analytical pure) and oleic acid (analytical pure) were mixed according to the stoichiometric ratio of 1:3, then 5 mL of octadecene (analytical pure) was added, nitrogen gas was introduced, and the mixture was heated to 120 ° C until the powder was completely dissolved and then cooled to room temperature. The concentration of Cs ions in the resulting solution was 5.0 mol / 42.5 mL. Mix PbO (analytical pure) and oleic acid in a stoichiometric ratio of 1:3, then add 5 mL of octadecene, blow in nitrogen, heat the mixture to 120 °C, and cool to room temperature until the powder is completely dissolved. The concentration of Pb ions in the obtained solution was 1.0 mol / L. After preheating the above two solutions at 80°C, mix 0.4mL and 0.5mL with 0.5mL oleylamine and 5mL octadecene respectively, heat the mixture to 150°C, then inject 0.2mL iodotrimethylsilane rapidly, and react After 5s, cool the device with an ice-water bath, and the resulting solution is CsPb...

Embodiment 3

[0026] Will Cs 2 CO 3 (analytical pure) and oleic acid (analytical pure) were mixed according to the stoichiometric ratio of 1:2, then 5 mL of octadecene (analytical pure) was added, nitrogen gas was introduced, and the mixture was heated to 120 °C until the powder was completely dissolved and then cooled to room temperature. The concentration of Cs ions in the resulting solution was 5.0 mol / 42.5 mL. Mix PbO (analytical pure) and oleic acid in a stoichiometric ratio of 1:2, then add 5 mL of octadecene, blow in nitrogen, heat the mixture to 120 °C, and cool to room temperature until the powder is completely dissolved. The concentration of Pb ions in the obtained solution was 1.0 mol / L. After the above two solutions were preheated at 80°C, 0.4mL and 0.5mL were mixed with 0.4mL oleylamine and 5mL octadecene respectively, and the mixture was heated to 150°C, followed by rapid injection of 0.2mL iodotrimethylsilane, and the reaction After 5s, cool the device with an ice-water ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com