A reforming device for burning biomass in a circulating fluidized bed coal-fired boiler

A technology of circulating fluidized bed and coal-fired boilers, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., and can solve the problem of not being able to carry the design load of boiler steam production, insufficient return material, and accelerated flue gas flow and other problems, to achieve the effect of solving the shortage of returned ash, increasing the amount of returned ash, and increasing the load of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory and should not have any limitation on the scope of protection of the present invention. .

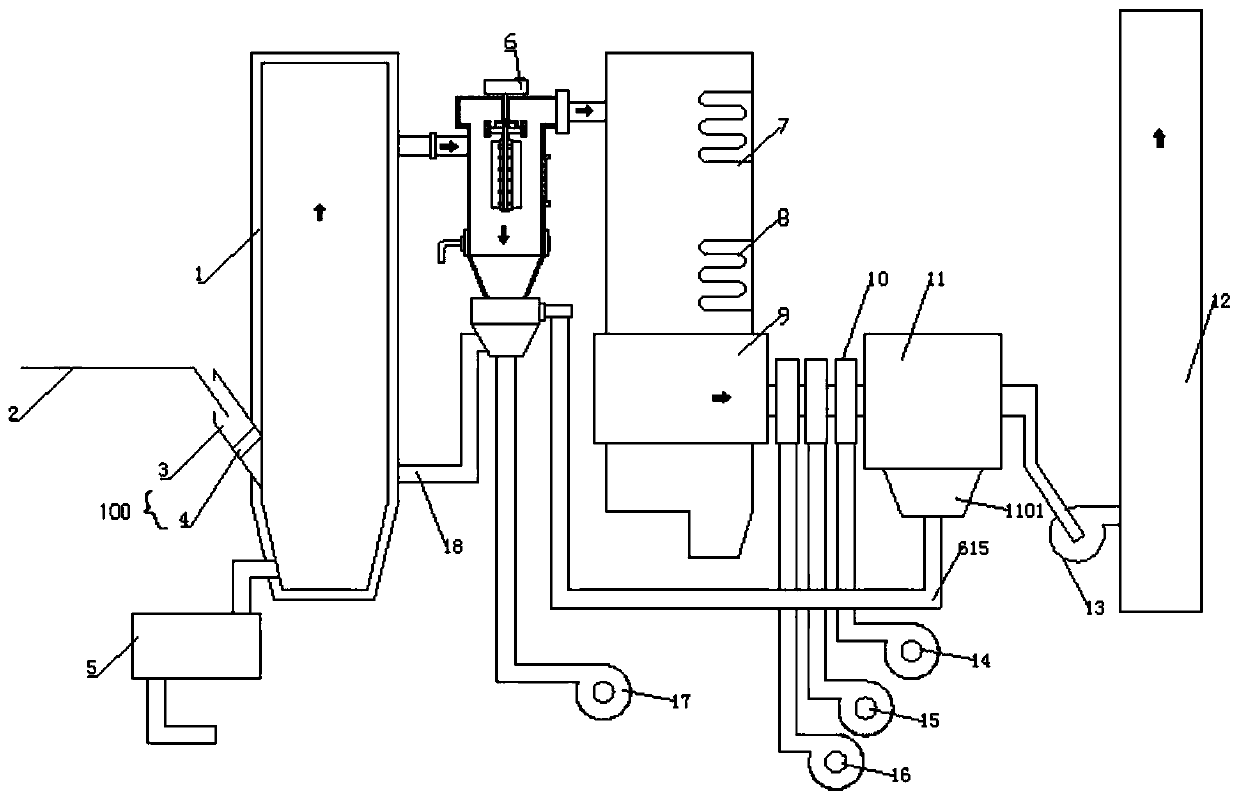

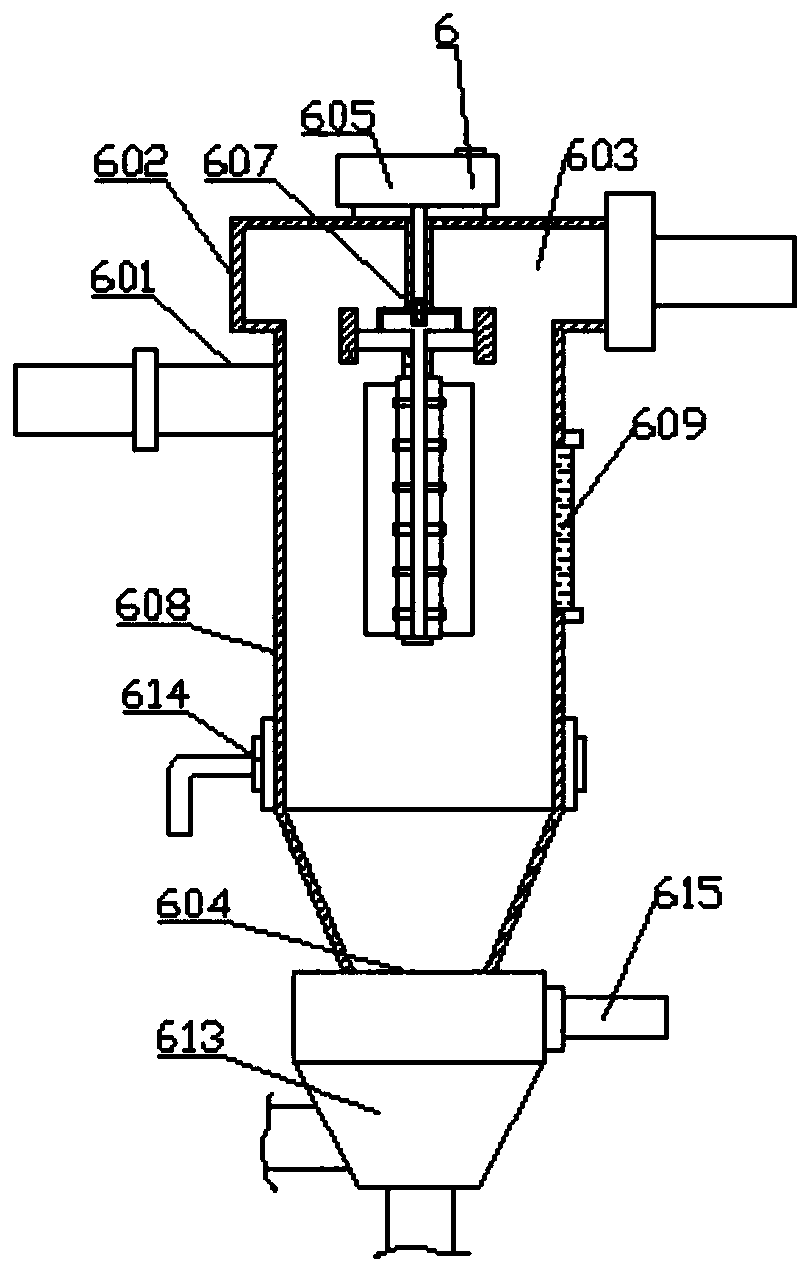

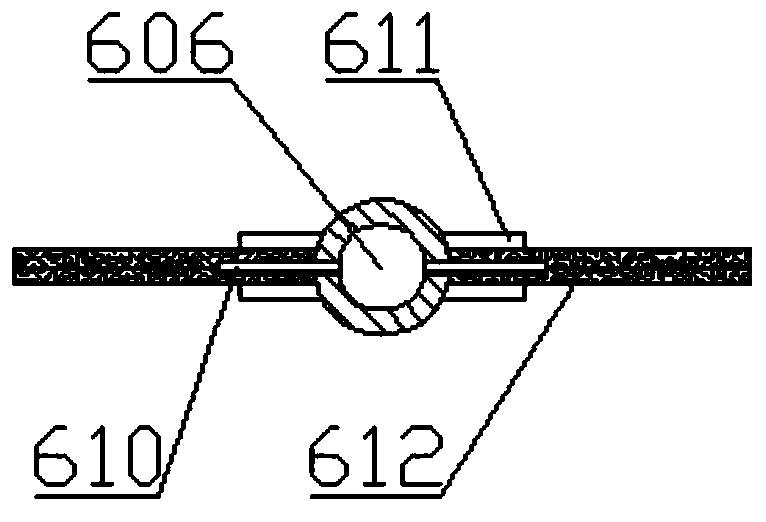

[0027] Such as Figure 1-Figure 3 As shown, the specific structure of the present invention is:

[0028] A reforming device for burning biomass in a circulating fluidized bed coal-fired boiler. It includes a furnace 1. The lower and side ends of the furnace 1 are respectively provided with a cooler 5 and a return system optimization device 6, and the lower end of the return system optimization device 6 A blower 17 is provided. The side end of the return system optimization device 6 is connected to the filter 7, the first economizer 8, and the air preheater 9. The air preheater 9 is connected to the dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com