Pixel definition layer based on ink-jet printing and preparation method thereof

A pixel-defining layer, inkjet printing technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of water vapor and oxygen permeability, high light transmittance, poor bottom spreading, etc., to improve stability , expand the range of choices, avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

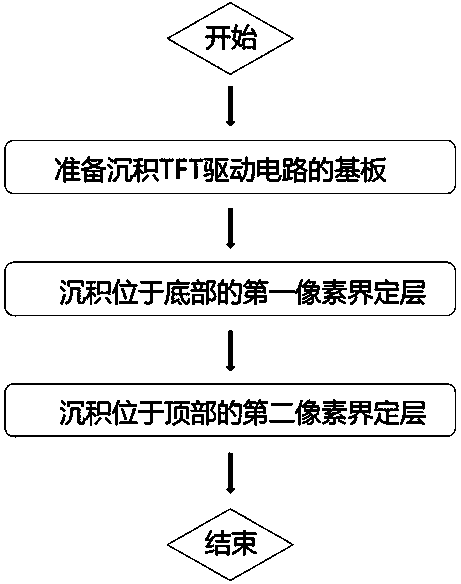

[0029] A pixel-defining layer based on inkjet printing, the specific preparation method of which is:

[0030] In the first step, a silicon substrate is provided, which is ultrasonically cleaned with acetone, alcohol, and deionized water in an atmospheric environment, dried, and deposited with TFT drive circuits and anodes, such as figure 2 ;

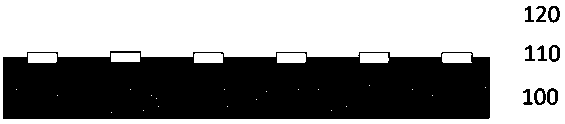

[0031] In the second step, use a fine metal mask to vapor-deposit a 100 nm-thick aluminum oxide on the substrate as the first pixel defining layer, such as image 3 ;

[0032] The third step is to dissolve polymethyl methacrylate (PMMA) and polystyrene (PS) at a certain stoichiometric ratio in tetrahydrofuran to make a polymer ink, and then prepare a patterned bank by inkjet printing, and let the tetrahydrofuran After the solvent evaporates, soak it in cyclohexane for a certain period of time, take it out, and let it dry naturally to obtain a hydrophobic second pixel defining layer with a thickness of 0.9 μm, as shown in Figure 4 . ...

Embodiment 2

[0034] A pixel-defining layer based on inkjet printing, the specific preparation method of which is:

[0035] In the first step, a silicon substrate is provided, which is ultrasonically cleaned with acetone, alcohol, and deionized water in an atmospheric environment, dried, and deposited with TFT drive circuits and anodes, such as figure 2 ;

[0036] In the second step, use a fine metal mask to sputter a layer of aluminum oxide with a thickness of 100 nm on the substrate as the first pixel defining layer, such as image 3 ;

[0037] The third step is to dissolve polymethyl methacrylate (PMMA) and polystyrene (PS) at a certain stoichiometric ratio in tetrahydrofuran to make a polymer ink, and then prepare a patterned bank by inkjet printing, and let the tetrahydrofuran After the solvent evaporates, soak it in cyclohexane for a certain period of time, take it out, and let it dry naturally to obtain a hydrophobic second pixel defining layer with a thickness of 0.9 μm, as shown...

Embodiment 3

[0039] A pixel-defining layer based on inkjet printing, the specific preparation method of which is:

[0040] In the first step, a silicon substrate is provided, which is ultrasonically cleaned with acetone, alcohol, and deionized water in an atmospheric environment, dried, and deposited with TFT drive circuits and anodes, such as figure 2 ;

[0041] In the second step, a 100-nm-thick aluminum oxide nanoparticle is deposited on the substrate as the first pixel-defining layer using a photolithography process, such as image 3 ;

[0042] The third step is to dissolve polymethyl methacrylate (PMMA) and polystyrene (PS) at a certain stoichiometric ratio in tetrahydrofuran to make a polymer ink, and then prepare a patterned bank by inkjet printing, and let the tetrahydrofuran After the solvent evaporates, soak it in cyclohexane for a certain period of time, take it out, and let it dry naturally to obtain a hydrophobic second pixel defining layer with a thickness of 0.9 μm, as sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com