A kind of preparation method of dental composite resin material and its prepared product

A composite resin and dental technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve problems such as low double bond conversion rate and incomplete resin curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

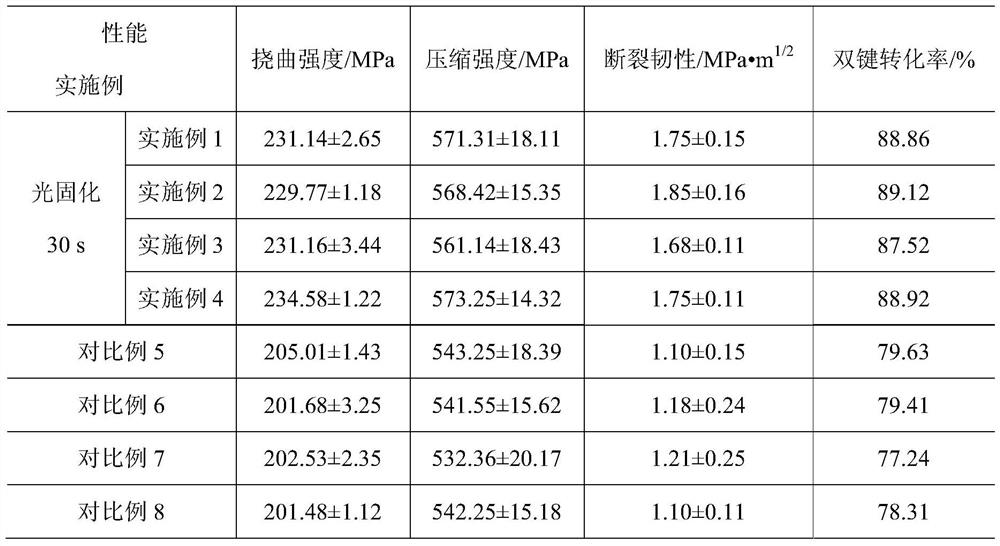

Examples

preparation example Construction

[0030] In order to solve the problems of the prior art, the invention provides a method for preparing a dental composite resin material, the method comprising:

[0031] (1), weighing raw materials, said raw materials include: resin monomers, fillers, photocuring initiators, thermal curing initiators, wherein said resin monomers include ethylenically unsaturated monomers and / or epoxy resins monomer, the ratio of the weight of the resin monomer to the filler is 10:90-90:10, preferably 15:85-50:50; the total amount of the photocuring initiator and thermal curing initiator accounts for 0.1-2% of the weight of the resin monomer, and the weight ratio of the photocuring initiator to the thermal curing initiator is 0.1:99.9-99.9:0.1, preferably 10:90-90:10.

[0032] In practical applications, resin monomers can be selected from polymerizable ethylenically unsaturated compounds with or without acid functional groups such as acrylates, methacrylates, hydroxyl-functionalized acrylates, h...

Embodiment 1

[0073] Weigh the raw materials according to the formula of Example 1 in Table 1, carry out surface modification treatment on the weighed fillers and reinforcing fibers, and then mix the surface modified fillers with the weighed raw materials to obtain the composite resin precursor things. The composite resin precursor was mixed by ball milling, wherein the mass ratio of composite resin precursor: grinding balls: ball milling aid was 2:4:1, and the ball milling time was 1.5 h. The ball-milled composite resin precursor was mixed with the surface-modified reinforcing fiber, and the mixed composite resin precursor was rotary evaporated at 55° C. for 1.5 h. The dried composite resin precursor was dried at 54° C. for 4 hours.

[0074] Then, the dry-press preforming, heat-curing process conditions and ultraviolet light-curing process conditions in Table 1 were used to heat-cure and light-cure the dried composite resin precursor to obtain a dental composite resin material.

Embodiment 2

[0075] Examples 2-4 adopted the raw material formulations and preparation process conditions recorded in Table 1, and prepared dental composite resin materials according to the preparation method described in Example 1. Wherein, in embodiment 2, before filler lanthanum glass powder, nano zirconium dioxide are mixed with other raw materials, carry out coupling agent modification treatment earlier, processing method and embodiment 1, filler barium glass powder, nano silicon dioxide The processing method is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com