An improved preparation process of synthetic diamond sintered body

An artificial diamond and improved technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of reducing the overall hardness and wear ratio of the sintered body, single component, and loss of hardness of the sintered body. Achieve the effects of shortening the preparation time, improving the preparation efficiency and facilitating demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

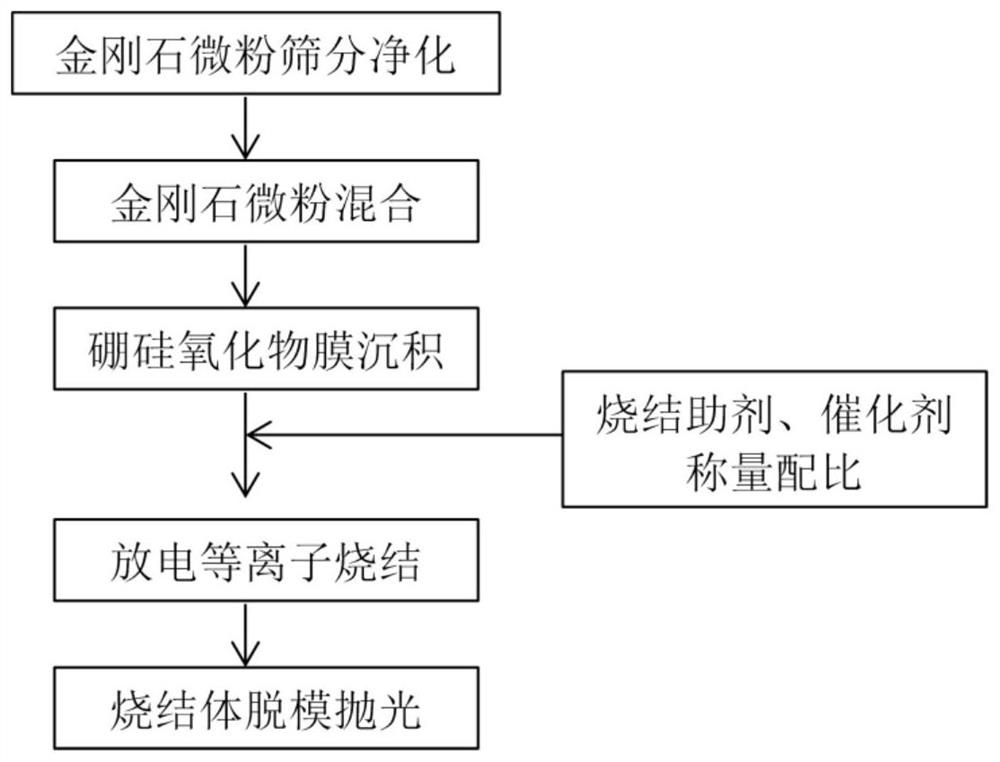

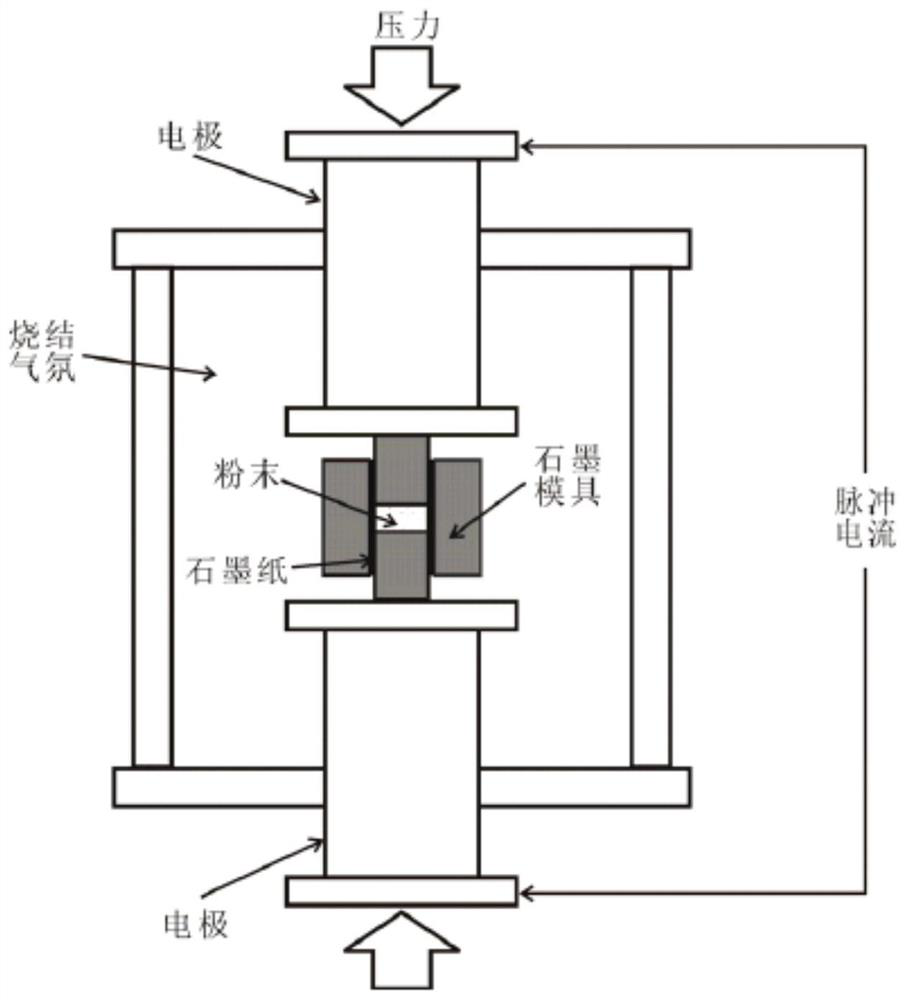

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: prepare diamond sintered compact according to the following method:

[0044] (1) Sieve the diamond powder into three specifications of 15 μm, 25 μm, and 35 μm, mix it according to the weight ratio of 2:2:1, then purify the diamond powder, and place the diamond powder in NaOH and HCl solutions and boil for 25 minutes respectively , washed with distilled water until neutral, dried for later use;

[0045] (2) Fill gaseous methane silicon, diborane, and oxygen with a purity of 99.0% in a molar ratio of 2:1:10 at room temperature into a chemical vapor deposition equipment with a vacuum of 8Pa, so that the deposition pressure is 400Pa, and the deposition reaction temperature 350°C, deposition time 35min, chemical vapor deposition is carried out on the surface of artificial diamond powder to form B with a thickness of 5-10nm 2 o 3 ·SiO2 2 In the borosilicate oxide film, the mass fraction of germanium-silicon alloy in the diamond-coated micropowder is 0.5-2mass%....

Embodiment 2

[0051] Embodiment 2: prepare diamond sintered compact according to the following method:

[0052] (1) Sieve the diamond powder into three specifications of 15 μm, 25 μm, and 35 μm, mix it according to the weight ratio of 2:2:1, purify the diamond powder, and place the diamond powder in 4M NaOH and 1M HCl solution in sequence Boil them for 40 minutes, wash with distilled water until neutral, and dry for later use;

[0053] (2) Fill gaseous methane silicon, diborane, and oxygen with a purity of 99.99% in a molar ratio of 2:1:10 at room temperature into a chemical vapor deposition equipment with a vacuum of 8Pa, so that the deposition pressure is 800Pa, and the deposition reaction temperature 450°C, deposition time 55min, chemical vapor deposition is carried out on the surface of artificial diamond powder to form B with a thickness of 10-20nm 2 o 3 ·SiO2 2 The borosilicate oxide film, the mass fraction of germanium-silicon alloy in the diamond-coated micropowder is 2-4mass%. ...

Embodiment 3

[0059] Embodiment 3: prepare diamond sintered compact according to the following method:

[0060] (1) Sieve the diamond powder into three specifications of 15 μm, 25 μm, and 35 μm, mix it according to the weight ratio of 2:2:1, purify the diamond powder, and place the diamond powder in NaOH and HCl solutions in turn and boil for 30 minutes respectively , washed with distilled water until neutral, dried for later use;

[0061] (2) Fill gaseous methane silicon with a purity of 99.5%, diborane and oxygen in a molar ratio of 2:1:10 at room temperature into a chemical vapor deposition equipment with a vacuum of 8Pa, so that the deposition pressure is 600Pa and the deposition reaction temperature 400°C, deposition time 45min, chemical vapor deposition on the surface of artificial diamond powder to form B with a thickness of 8-15nm 2 o 3 ·SiO2 2 The borosilicate oxide film, the mass fraction of germanium-silicon alloy in the diamond-coated micropowder is 1.5-3mass%.

[0062] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com