Preparation methods of carbon quantum dots and carbon quantum dot and MOFs (Metal Organic Frameworks) composite thin film and product and application of composite thin film

A technology of carbon quantum dots and composite thin films, applied in the field of material preparation, to achieve the effects of mild conditions, good temperature response, and rapid and efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The microwave method synthesis of embodiment 1 carbon quantum dot

[0060] Weigh 5 grams of glucose and ultrasonically dissolve it in 12.5 milliliters of deionized aqueous solution, then put it into a 50 milliliter microwave reaction tube, and put the cleaned zinc sheet vertically into the reaction tube, seal it, and put it in a microwave instrument. Between 100-130 degrees, the time is 1-2 hours. With the extension of time, carbon quantum dots with higher concentration can be obtained.

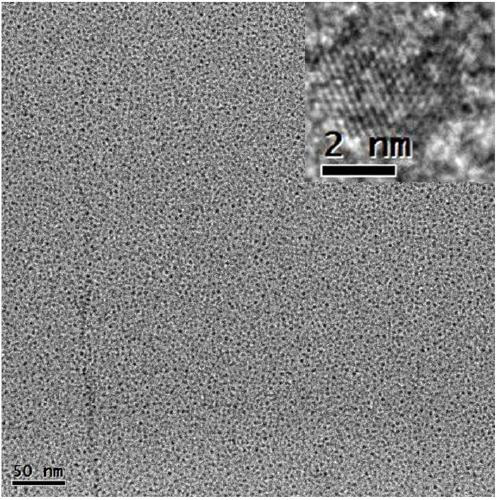

[0061] The carbon quantum dot prepared above is carried out transmission electron microscope scanning, obtains the transmission electron microscope scanning figure of carbon quantum dot, specifically as follows figure 1 shown.

Embodiment 2

[0062] Embodiment 2 has the synthesis of the MOFs material of carboxylic acid functional group

[0063] A typical synthesis strategy is: weigh 2.3 grams of zirconium chloride, dissolve it in 50 milliliters of deionized water, then weigh 4.3 grams of pyromellitic acid and add it to obtain a mixture, and stir the above mixture at 100° C. for 24 hours, Obtain a solid material, then centrifuge the solid material with deionized water three times, then disperse it in deionized water at 100°C and continue to stir for 16 hours, then wash it twice with deionized water and acetone, and finally put it into a vacuum at 60°C Dry overnight in a desiccator to obtain MOFs materials with carboxylic acid functional groups.

Embodiment 3

[0064] Embodiment 3 has the synthesis of the MOFs material of carboxylic acid functional group

[0065] The method is the same as in Example 2, except that 1.3 grams of aluminum chloride is used to replace the 2.3 grams of zirconium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com