A kind of preparation method of nanoscale superfine sodium chloride

A sodium chloride and nano-level technology is applied in the field of preparation of nano-level ultrafine sodium chloride, which can solve the problems of good dispersibility, inability to obtain a particle size range, low yield and the like, and achieves a reduction in specific gravity and a uniform molding process. and continuous, the effect of inhibiting crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At room temperature, dissolve 50g of sodium hydroxide and 5g of sodium stearate in 1Kg of absolute ethanol solution; dissolve 200g of fatty alcohol polyoxyethylene ether in 800g of hexadecane solution; mix the two evenly, and mix them thoroughly for 20 minutes Afterwards, HCl gas was fed into the mixture while stirring, the gas flow rate was 1 L / min, and the mixture was ventilated for 5 hours and then allowed to stand for 12 hours.

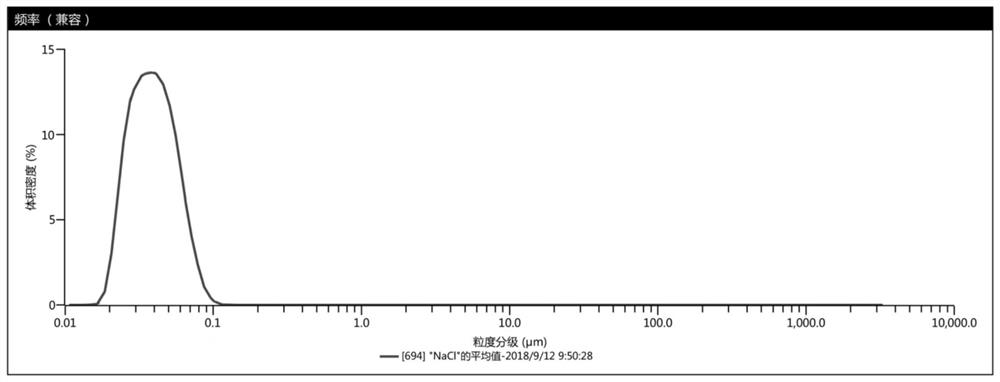

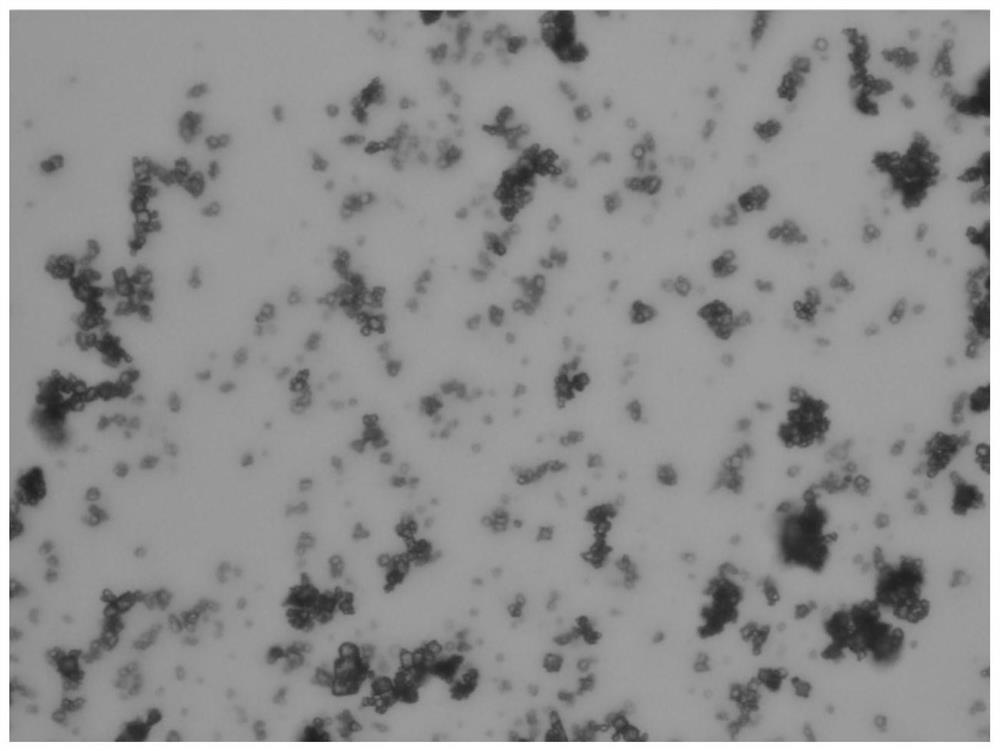

[0034] After standing still, acetone is added to destroy the state of the microemulsion by ultrasonication, centrifuged, and the collected precipitate is washed with acetone three times to collect crystals, and finally dried in a vacuum oven to obtain nano-scale sodium chloride. For its particle size distribution, see figure 1 , electron microscope see figure 2 .

Embodiment 2

[0036] At room temperature, dissolve 5g of sodium acetate and 0.5g of sodium stearate in 800g of absolute ethanol solution; dissolve 200g of lauryl ether phosphate in 1.5Kg of hexadecane solution; mix the two evenly and thoroughly After 20 min, HCl gas was fed into the mixture while stirring, the gas flow rate was 0.5 L / min, the mixture was ventilated for 5 h and then allowed to stand for 10 hours.

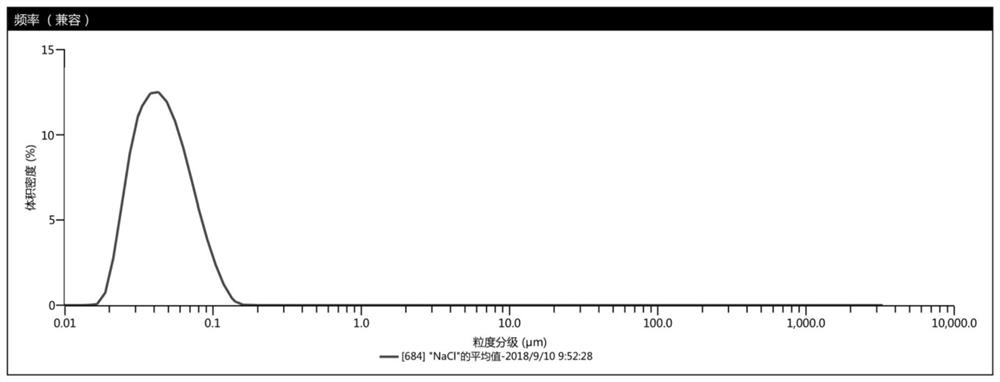

[0037] After standing still, acetone is added to destroy the state of the microemulsion by ultrasonication, centrifuged, and the collected precipitate is washed with acetone three times to collect crystals, and finally dried in a vacuum oven to obtain nano-scale sodium chloride. For its particle size distribution, see image 3 , electron microscope see Figure 4 .

Embodiment 3

[0039] At room temperature, dissolve 2 g of sodium bicarbonate and 0.1 g of sodium stearate in 400 g of absolute ethanol solution; dissolve 40 g of disodium sulfosuccinate monoester in 160 g of hexadecane solution; mix the two evenly, After thorough mixing for 20 minutes, HCl gas was fed in the stirred state, the gas flow rate was 0.5 L / min, the mixture was ventilated for 2 hours and then allowed to stand for 8 hours.

[0040] After standing still, acetone is added to destroy the state of the microemulsion by ultrasonication, centrifuged, and the collected precipitate is washed with acetone three times to collect crystals, and finally dried in a vacuum oven to obtain nano-scale sodium chloride. For its particle size distribution, see Figure 5 , electron microscope see Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com