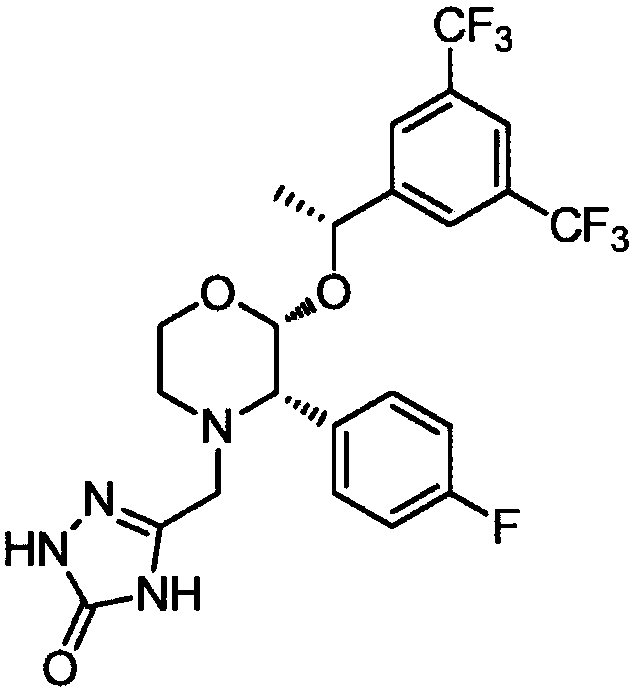

Preparation process of aprepitant

A preparation process and aprepitant technology, applied in the field of aprepitant preparation technology, can solve the problems of unsatisfactory purity, low yield, and high impurity content, and achieve an optimized formula, low impurity content, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

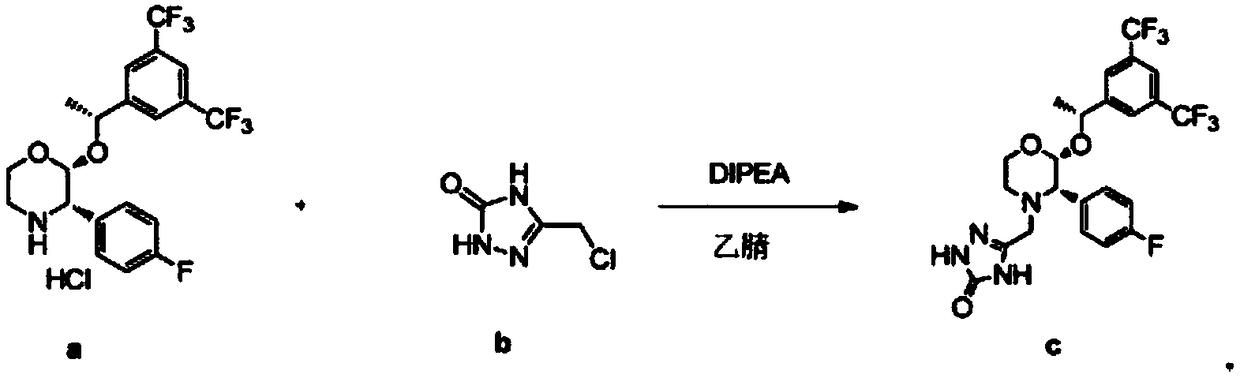

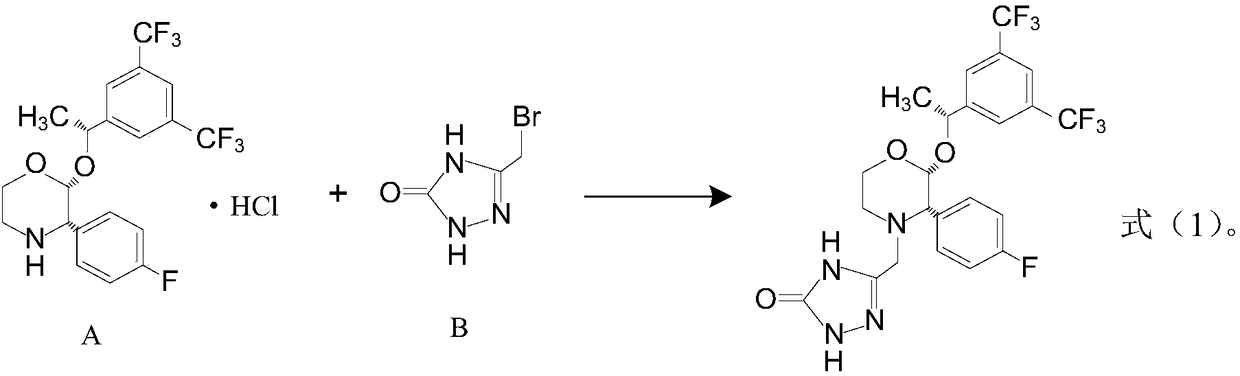

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a preparation process of aprepitant, comprising the following steps:

[0040] Setp1, first add compound A and compound B to a mixed solvent of N,N-dimethylformamide and triethylamine and stir to dissolve to obtain a mixed solution; wherein, the mass ratio of compound A to compound B is 1.3; in the mixed solvent, N , The mass ratio of the mixed solvent of N-dimethylformamide and triethylamine is 1:0.3, and the solute mass fraction of the mixed solution is 45%.

[0041] Setp2, under a nitrogen atmosphere, add lithium diisopropylamide to the mixed solution for uniform mixing; wherein, the added mass of lithium diisopropylamide is 1 / 3 of the sum of the mass of compound A and compound B.

[0042] Setp3, under nitrogen protection and stirring conditions, add dropwise a solution of diethyl sulfate in xylene; the quality of adding diethyl sulfate is 0.05% of the mass sum of compound A and compound B, the solution of diethyl sulfate in xylene The mass p...

Embodiment 2

[0058] This embodiment provides a preparation process of aprepitant, comprising the following steps:

[0059] Setp1, first add compound A and compound B to a mixed solvent of N,N-dimethylformamide and triethylamine and stir to dissolve to obtain a mixed solution; wherein, the mass ratio of compound A to compound B is 2.0; in the mixed solvent, N , The mass ratio of the mixed solvent of N-dimethylformamide and triethylamine is 1:0.3, and the mass fraction of solute in the mixed solution is 20%.

[0060] Setp2, under a nitrogen atmosphere, add lithium diisopropylamide to the mixed solution for uniform mixing; wherein, the added mass of lithium diisopropylamide is 1 / 3 of the sum of the mass of compound A and compound B.

[0061]Setp3, under nitrogen protection and stirring conditions, add dropwise the solution of diethyl sulfate in xylene; the quality of adding diethyl sulfate is 0.10% of the mass sum of compound A and compound B, the solution of diethyl sulfate in xylene The ma...

Embodiment 3

[0077] This embodiment provides a preparation process of aprepitant, comprising the following steps:

[0078] Setp1, first add compound A and compound B to a mixed solvent of N,N-dimethylformamide and triethylamine and stir to dissolve to obtain a mixed solution; wherein, the mass ratio of compound A to compound B is 1.6; in the mixed solvent, N , The mass ratio of the mixed solvent of N-dimethylformamide and triethylamine is 1:0.3, and the solute mass fraction of the mixed solution is 34%.

[0079] Setp2, under a nitrogen atmosphere, add lithium diisopropylamide to the mixed solution for uniform mixing; wherein, the added mass of lithium diisopropylamide is 1 / 3 of the sum of the mass of compound A and compound B.

[0080] Setp3, under nitrogen protection and stirring conditions, add dropwise the xylene solution of diethyl sulfate; the added quality of diethyl sulfate is 0.07% of the mass sum of compound A and compound B, the xylene solution of diethyl sulfate The mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com