Linear polyphosphazene compound and preparation method and application thereof

A compound and a technology for polydichlorophosphazene, which are applied in the field of linear polyphosphazene compounds and their preparation, can solve problems such as unfavorable large-scale production, complex synthesis method, limited types, etc., and achieve easy storage and transportation, simple preparation method, high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] Use of the compound of the present invention or the compound prepared by the method for preparing the compound of the present invention

[0094] In the third aspect of the present invention, the present invention proposes the use of the compound of the above-mentioned embodiment or the compound prepared by the method for preparing the compound of the above-mentioned embodiment as a catalyst in a polymerization reaction. According to the embodiments of the present invention, the compounds of the above-mentioned embodiments of the present invention or the compounds prepared by the method for preparing compounds in the above-mentioned embodiments can be used as catalysts for the preparation of polymers, such as ester copolymers, ether copolymers and polyesters, Polyether and polycarbonate copolymers, and the prepared polymer product structure is easy to control and has a variety of types. At the same time, the product does not contain heavy metal elements, has low catalyst ...

Embodiment 1

[0107] Preparation of polydichlorophosphazene

[0108]

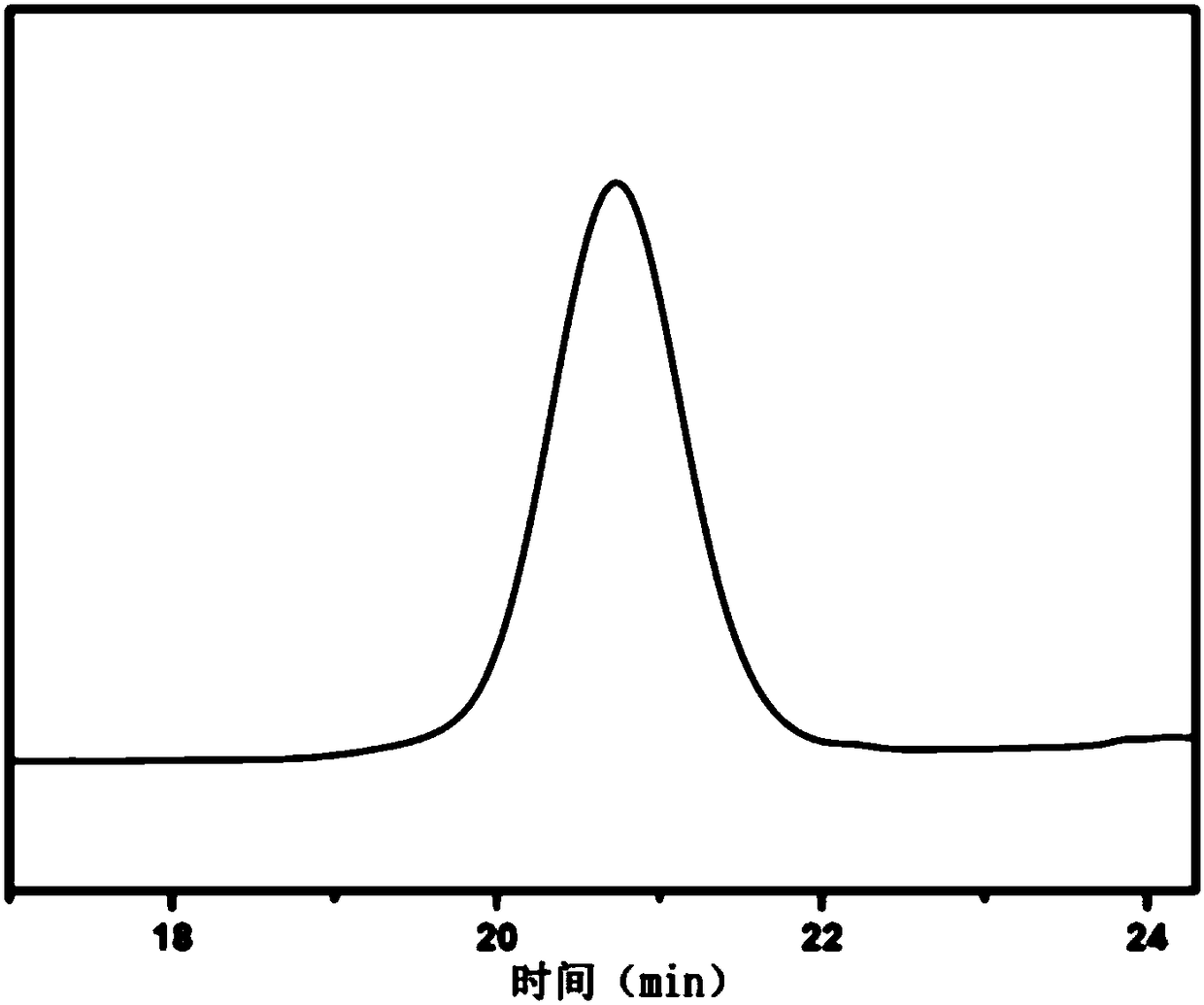

[0109] Add the purified hexachlorocyclotriphosphazene (3.5g) and the catalyst into a narrow-necked glass tube, and use a flame spray gun to melt and burn the narrow neck of the glass tube to seal the tube under vacuum, and then put it into the preheated tube to 250°C after cooling slightly. In the oil bath, stop heating when the substance in the tube changes from molten flowing hexachlorocyclotriphosphazene to immobile translucent gel. Cut the glass tube, add dry n-hexane to remove unreacted hexachlorocyclotriphosphazene, then add dry tetrahydrofuran under the protection of nitrogen, dissolve the product linear polydichlorophosphazene, filter out the insoluble cross-linked product, and obtain poly dichlorophosphazene solution in tetrahydrofuran. m n,GPC =11500g mol -1 ,M w / M n = 1.03.

Embodiment 2

[0111] Preparation of Tris(dimethylamino)phosphazene / Dimethylamino Substituted Linear Polyphosphazene

[0112]

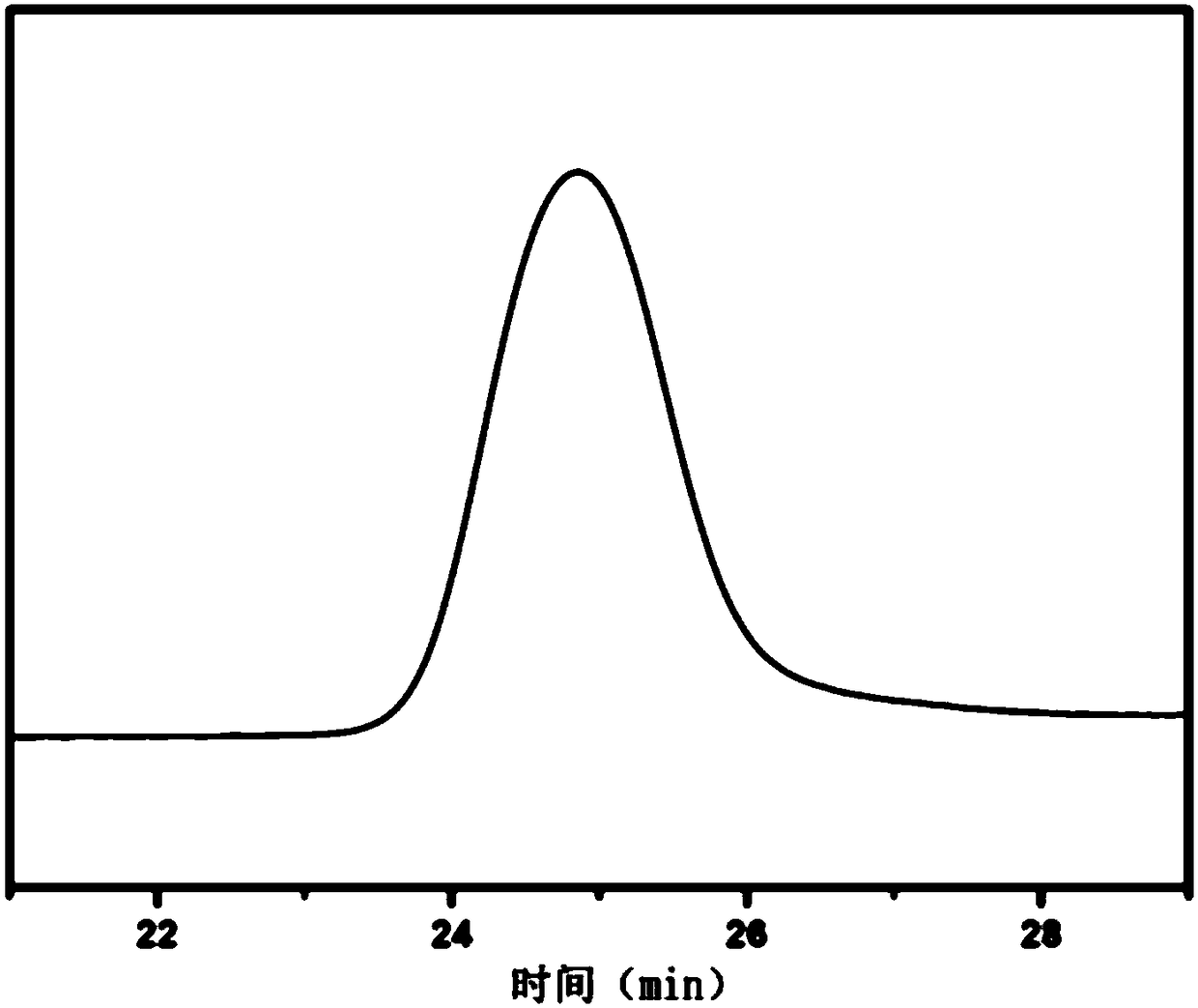

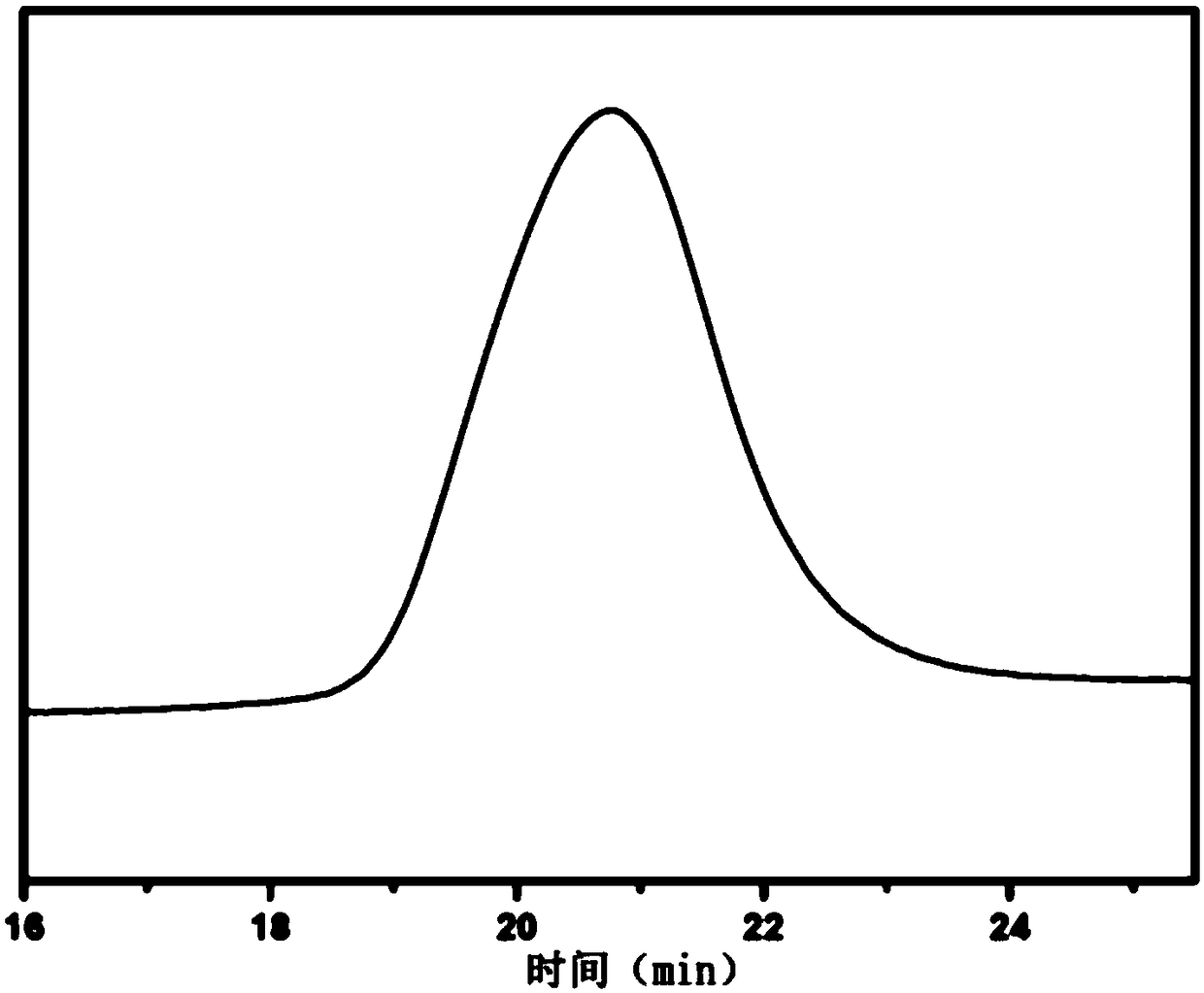

[0113] Under the protection of nitrogen, polydichlorophosphazene (3.5g, 30mmol containing phosphorus and nitrogen double bonds, 3.0equiv.) tetrahydrofuran solution 60mL and triethylamine (8.3mL, 60mmol, 6.0equiv.) were added to the 250mL condensate reflux tube In a three-necked flask, place it in a low-temperature bath at -30°C and keep stirring. Tris(dimethylamine)phosphazene (5.3 g, 30 mmol, 3.0 equiv.) was continuously added dropwise to the reaction system to keep the solution temperature below -20°C. After the dropwise addition, the temperature of the system was naturally raised to 20° C., placed in an oil bath, and refluxed for 12 hours. The temperature of the system was lowered to -50°C again, dimethylamine (2.7 g, 60 mmol, 6.0 equiv.) was introduced, and the temperature was raised to 20°C, and the reaction was continued for 2 hours. The insoluble matter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com