Graphene quantum dot-rare earth up-conversion nano composite material as well as preparation method and application thereof

A graphene quantum dot, nanocomposite material technology, applied in nanotechnology, nanotechnology, analytical materials and other directions, can solve the problems that limit the improvement of the sensitivity, selectivity and reliability of fluorescent immunosensors, and achieve high crystallinity, preparation Simple method and the effect of strong fluorescence emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

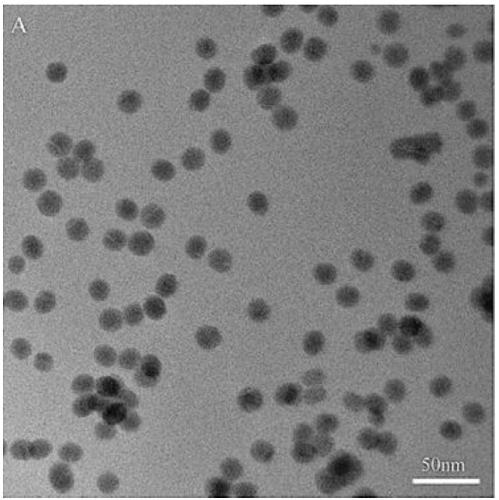

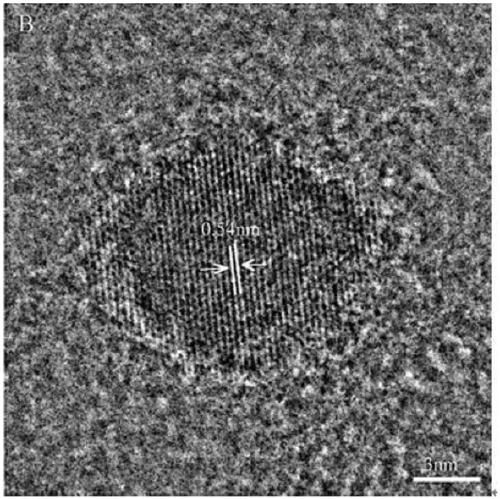

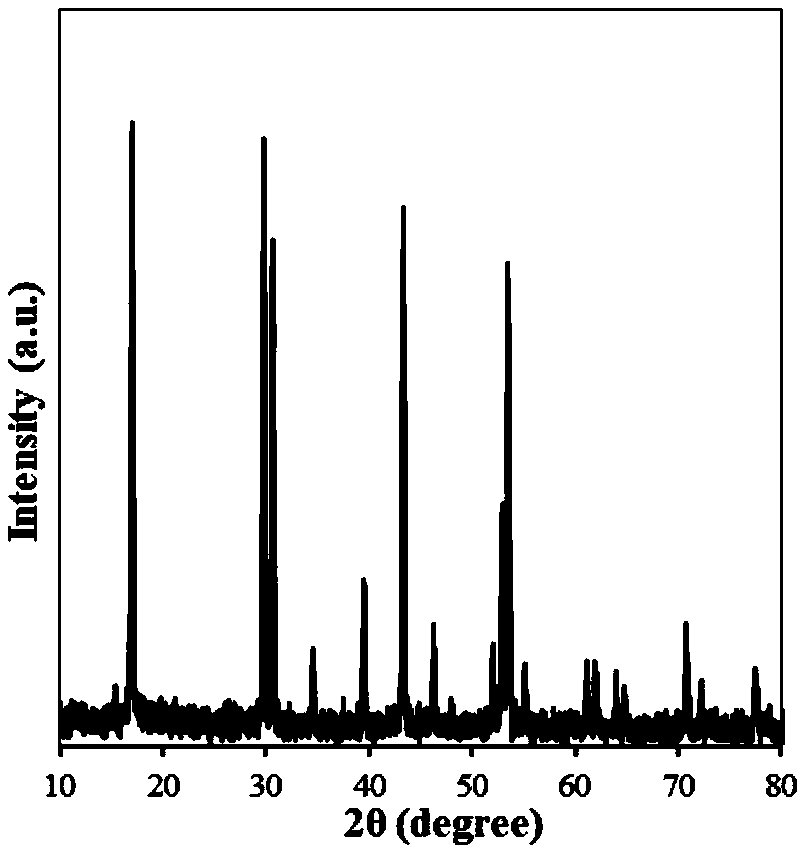

[0026] Example 1: Take 2.5g of citric acid monohydrate, 1.84g of L-histidine, and 0.55g of hexamethylenediamine in a 250ml beaker, add 5mL of deionized water to fully dissolve, put them in a reaction oven, and react at 170°C for 3h. The prepared histidine-hexamethylenediamine functionalized graphene quantum dots were formulated into a solution with a concentration of 25 mg / mL, and the pH was adjusted to neutral with an appropriate amount of sodium hydroxide solution. Add 1 mL of 0.78M YCl to the reaction vessel 3 solution, 1mL 0.2M YbCl 3 solution, 1mL 0.02M ErCl 3 solution, stir evenly at 500rpm, add 20ml of the above-prepared graphene quantum dot solution dropwise under stirring, keep stirring for 30min, then slowly add 6mL of 1M NaF solution dropwise, continue stirring for 1h, then transfer the mixed solution to the reaction kettle, 180℃ water Thermal reaction 4h. Take out the reacted solution and let it stand, take the supernatant and place it in a high-speed centrifuge...

Embodiment 2

[0027] Example 2: Take 2.5g of citric acid monohydrate, 2.02g of L-histidine, and 0.23g of hexamethylenediamine in a 250ml beaker, add 5mL of deionized water to fully dissolve it, put it in a reaction oven, and react at 180°C for 2h. The prepared histidine-hexamethylenediamine functionalized graphene quantum dots were formulated into a solution with a concentration of 50 mg / mL, and the pH was adjusted to neutral with an appropriate amount of sodium hydroxide solution. Add 1 mL of 0.78M YCl to the reaction vessel 3 solution, 1mL 0.2M YbCl 3 solution, 1mL 0.02M ErCl 3 solution, stir at 650rpm evenly, add 20ml of the above-prepared graphene quantum dot solution dropwise under stirring, keep stirring for 30min, then slowly add 4mL of 1M NaF solution dropwise, continue stirring for 1h, then transfer the mixed solution to the reaction kettle, 180℃ water Thermal reaction 3h. Take out the reacted solution and let it stand, take the supernatant and put it in a high-speed centrifuge tu...

Embodiment 3

[0028] Example 3: Take 2.5g of citric acid monohydrate, 1.47g of L-histidine, and 0.41g of hexamethylenediamine in a 250ml beaker, add 5mL of deionized water to fully dissolve, put them in a reaction oven, and react at 180°C for 2h. The prepared histidine-hexamethylenediamine functionalized graphene quantum dots were formulated into a solution with a concentration of 20 mg / mL, and the pH was adjusted to neutral with an appropriate amount of sodium hydroxide solution. Add 1 mL of 0.78M YCl to the reaction vessel 3 solution, 1mL 0.2M YbCl 3 solution, 1mL 0.02M ErCl 3 solution, stir at 600rpm evenly, add dropwise 30ml of the above-prepared graphene quantum dot solution under stirring, keep stirring for 30min, then slowly add 4mL of 1M NaF solution dropwise, continue stirring for 1h, then transfer the mixed solution to the reaction kettle, 180°C water Thermal reaction 4h. Take out the reacted solution and let it stand, take the supernatant and put it in a high-speed centrifuge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com