Method for degrading alcohol soluble protein

A technology of gliadin and keratinase, which is applied in the field of enzyme application, can solve problems affecting the economic benefits of breeding, reduce the digestibility of feed protein, and environmental nitrogen pollution, and achieve the goal of improving economic benefits of breeding, reducing nitrogen content, and high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

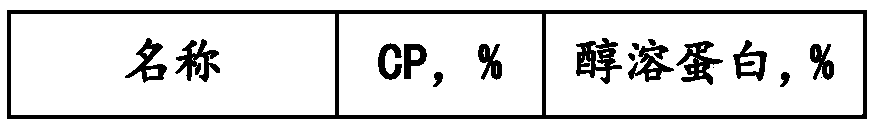

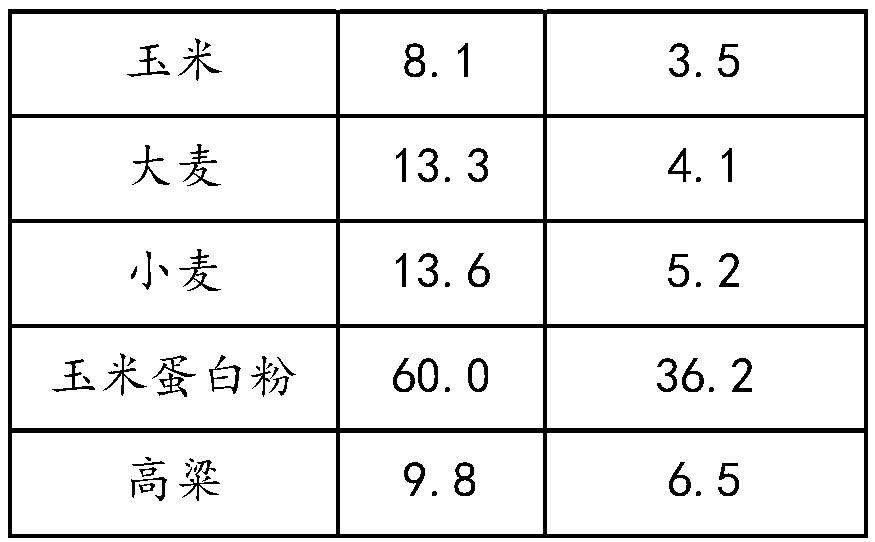

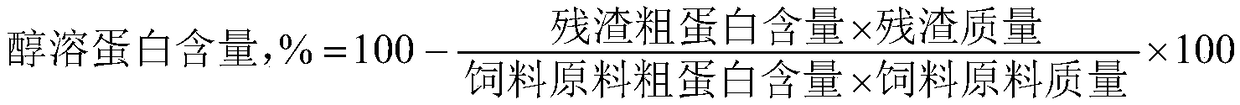

Method used

Image

Examples

Embodiment 1

[0022] The preparation of bacillus licheniformis producing keratinase comprises the following steps:

[0023] (1) Strain and culture medium preparation

[0024] Strains: keratinase strain Bacillus licheniformis, purchased from China Guangdong Microbial Culture Collection Center, the strain number is GIM1.11;

[0025] Media include slant broth media, expansion media, seed media and fermentation media;

[0026] Slope culture: broth medium composition: 0.8-1.2% beef extract, 0.8-1.2% peptone, 0.5% sodium chloride, 1.8-2.2% agar, pH7.2-7.5, sterilized at 118-122°C for about 30-40min ;

[0027] Expansion medium: 0.5% sodium chloride, 0.4%-0.6% yeast extract, 0.8%-1.2% beef extract, sterilized at 118-122°C for about 30-40min;

[0028] Primary seed medium: peptone 1.8%-2.2%, beef extract 0.8%-1%, sterilized at 118-122°C for about 30 minutes;

[0029] Secondary seed medium: corn steep liquor 5%-7%, defoamer 0.01%, ammonium sulfate 0.3%-0.4%, dextrin 2.0%-2.2%, glucose 0.6%-0.8%, s...

Embodiment 2

[0043] The preparation of bacillus licheniformis producing keratinase comprises the following steps:

[0044] (1) Strain and culture medium preparation

[0045] Strains: keratinase strain Bacillus licheniformis, purchased from China Guangdong Microbial Culture Collection Center, the strain number is GIM1.11;

[0046] Media include slant broth media, expansion media, seed media and fermentation media;

[0047]Slope culture: broth medium composition: 0.8-1.2% beef extract, 0.8-1.2% peptone, 0.5% sodium chloride, 1.8-2.2% agar, pH7.2-7.5, sterilized at 118-122°C for about 30-40min ;

[0048] Expansion medium: 0.5% sodium chloride, 0.4%-0.6% yeast extract, 0.8%-1.2% beef extract, sterilized at 118-122°C for about 30-40min;

[0049] Primary seed medium: peptone 1.8%-2.2%, beef extract 0.8%-1%, sterilized at 118-122°C for about 30 minutes;

[0050] Secondary seed medium: corn steep liquor 5%-7%, defoamer 0.01%, ammonium sulfate 0.3%-0.4%, dextrin 2.0%-2.2%, glucose 0.6%-0.8%, st...

Embodiment 3

[0064] The preparation of bacillus licheniformis producing keratinase comprises the following steps:

[0065] (1) Strain and culture medium preparation

[0066] Strains: keratinase strain Bacillus licheniformis, purchased from China Guangdong Microbial Culture Collection Center, the strain number is GIM1.11;

[0067] Media include slant broth media, expansion media, seed media and fermentation media;

[0068] Slope culture: broth medium composition: 0.8-1.2% beef extract, 0.8-1.2% peptone, 0.5% sodium chloride, 1.8-2.2% agar, pH7.2-7.5, sterilized at 118-122°C for about 30-40min ;

[0069] Expansion medium: 0.5% sodium chloride, 0.4%-0.6% yeast extract, 0.8%-1.2% beef extract, sterilized at 118-122°C for about 30-40min;

[0070] Primary seed medium: peptone 1.8%-2.2%, beef extract 0.8%-1%, sterilized at 118-122°C for about 30 minutes;

[0071] Secondary seed medium: corn steep liquor 5%-7%, defoamer 0.01%, ammonium sulfate 0.3%-0.4%, dextrin 2.0%-2.2%, glucose 0.6%-0.8%, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com