Silver enhanced lignin carbon/nano titanium dioxide compounded photocatalyst and preparation method and application thereof

A technology of nano-titanium dioxide and lignin carbon, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve high raw material costs, unfavorable catalyst reuse, silver Simple substances are easy to fall off and other problems, and achieve the effects of uniform distribution, improved photocatalytic efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Prepare 2g / L lignosulfonate solution and 2g / L C 14 TAB solution, by volume ratio 2:10 with C 14 The TAB solution is added to the lignosulfonate solution, and the precipitate is separated and dried to obtain a lignin complex. Dissolve 1.0 parts by volume of butyl titanate in 9 parts by volume of ethanol, then add 0.5 parts by mass of lignin compound and 0.4 parts by mass of silver nitrate, stir evenly, and then slowly add it dropwise to 30 parts by volume of distilled water, at 70 Stir at ℃ for 2h. The composite solution was centrifuged, washed twice with distilled water, and dried at 80° C. for 4 h. The obtained solid was ground into a powder, and then 2 Calcined at 500°C for 2h under protection, and cooled to room temperature to obtain a silver-enhanced lignin carbon / nano-titanium dioxide composite photocatalyst.

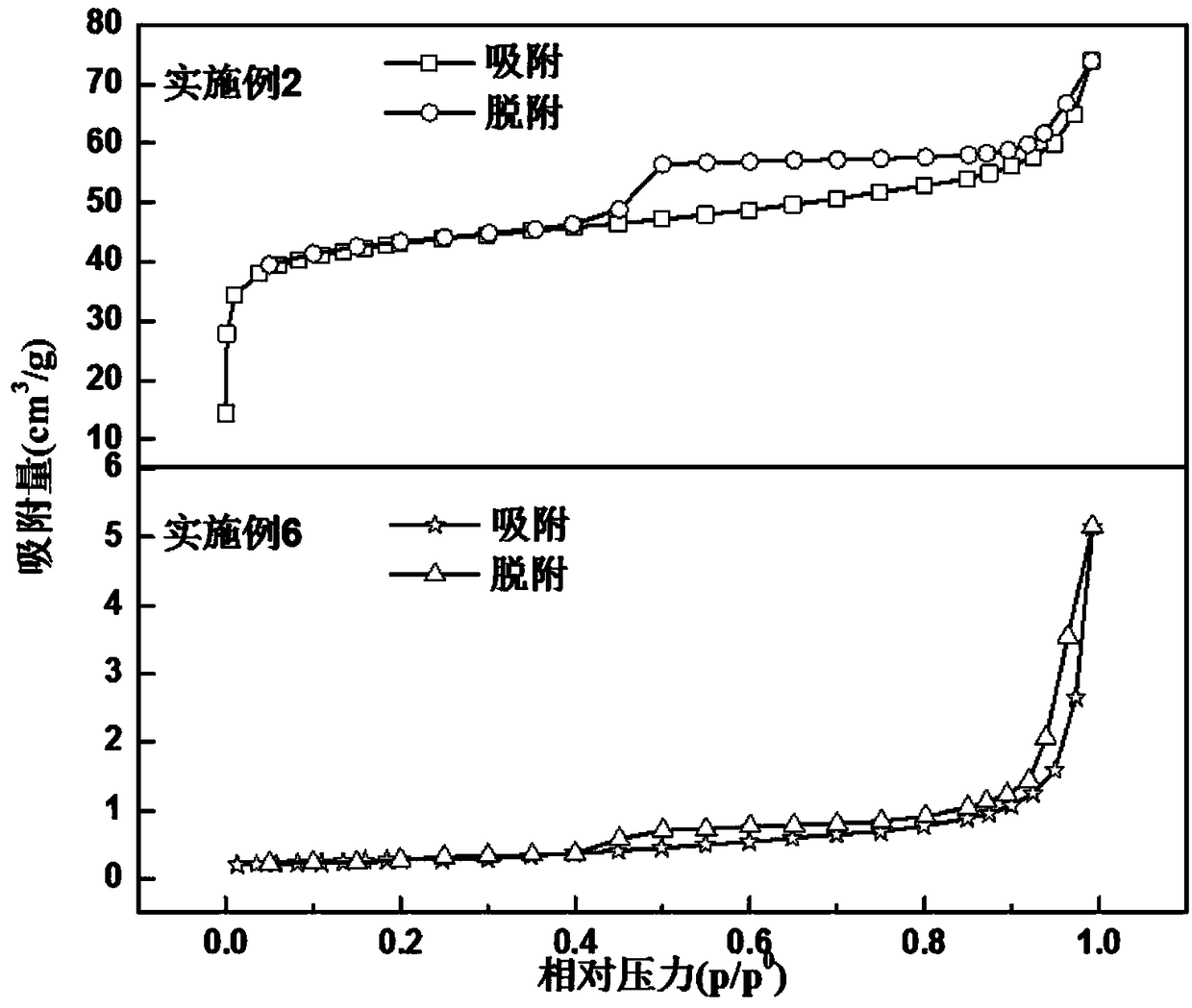

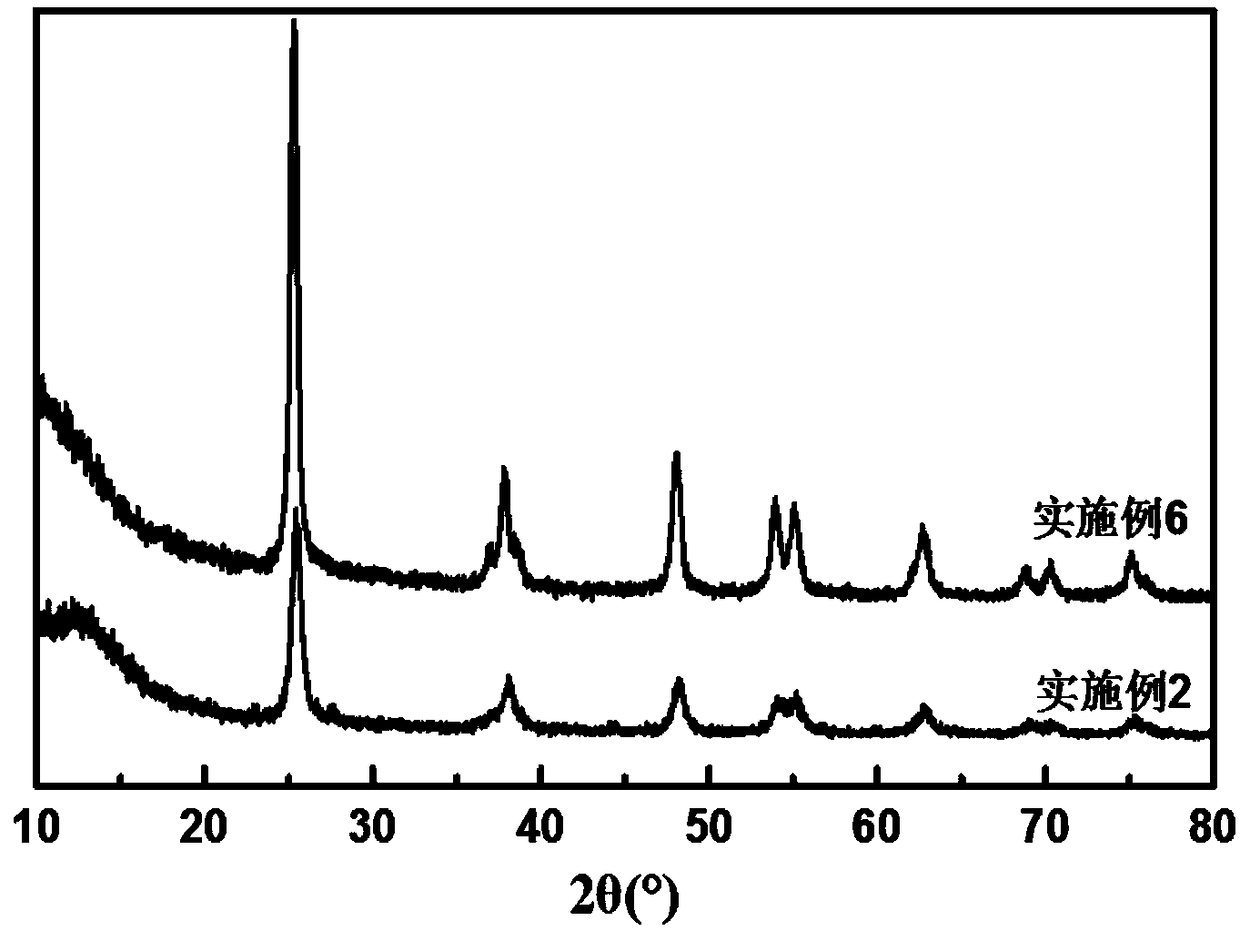

Embodiment 2

[0061] Prepare 2g / L lignosulfonate solution and 2g / L C 14 TAB solution, mix C with a volume ratio of 2:10 14 The TAB solution is added to the lignosulfonate solution, and the precipitate is separated and dried to obtain a lignin complex. Dissolve 1.0 parts by volume of titanium tetrachloride in 9 parts by volume of ethanol, add 0.5 parts by mass of lignin compound and 0.4 parts by mass of silver nitrate, stir evenly, and then slowly add it dropwise to 30 parts by volume of distilled water, at 70 Stir at ℃ for 2h. The composite solution was centrifuged, washed twice with distilled water, and dried at 80° C. for 4 h. The obtained solid was ground into a powder, and then 2 Calcined at 600°C for 2h under protection, and cooled to room temperature to obtain a silver-enhanced lignin carbon / nano-titanium dioxide composite photocatalyst.

Embodiment 3

[0063] Prepare 3g / L lignosulfonate solution and 3g / L C 14 TAB solution, by volume ratio 3:10 with C 14 The TAB solution is added to the lignosulfonate solution, and the precipitate is separated and dried to obtain a lignin complex. Dissolve 1.0 parts by volume of butyl titanate in 9 parts by volume of ethanol, add 0.5 parts by mass of lignin compound and 0.4 parts by mass of silver chlorate, stir evenly, and then slowly add it dropwise to 30 parts by volume of distilled water. Stir at 70°C for 2h. The composite solution was centrifuged, washed twice with distilled water, and dried at 80° C. for 4 h. The obtained solid was ground into a powder, and then 2 Calcined at 700°C for 2h under protection, and cooled to room temperature to obtain a silver-enhanced lignin carbon / nano-titanium dioxide composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com