Method and device for preparing and separating sec-butyl alcohol by sec-butyl acetate hydrolysis

A technology of sec-butyl acetate and sec-butanol, which is applied in the fields of hydrolysis preparation, carboxylate/lactone preparation, chemical instruments and methods, etc., can solve the problems of tower bottom alcohol, unstable operation, and sec-butanol content that cannot reach the standard And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

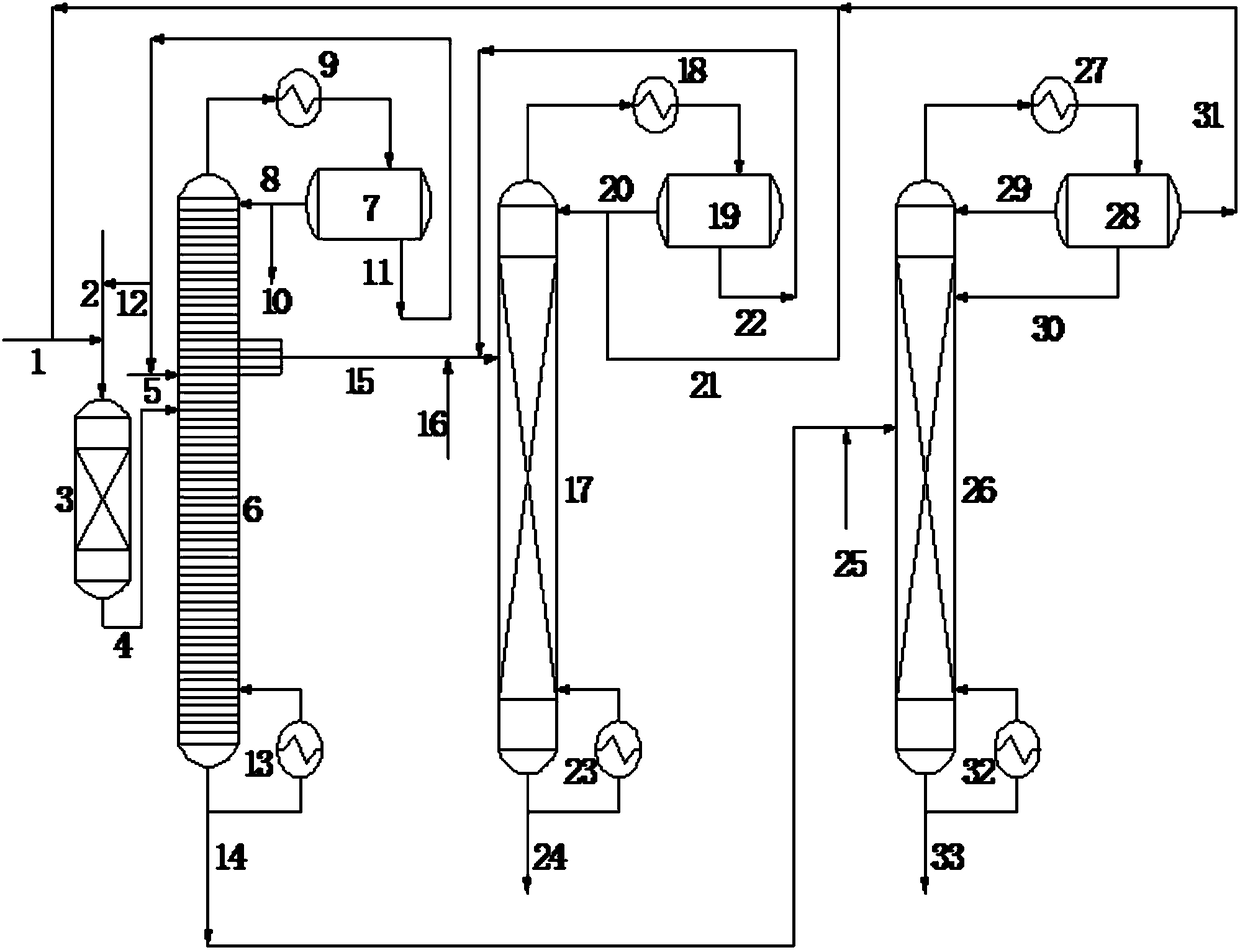

[0039] The sec-butyl acetate raw material is mixed with water according to the mass ratio of 1:1.5 and then sent to the hydrolysis reactor, and the reaction is carried out at a pressure of 0.8 MPa and a temperature of 90° C. to obtain sec-butyl alcohol, water, acetic acid and sec-butyl acetate Mixture; The reacted mixture is sent to the sec-butanol azeotropic rectification tower for separation, and the number of theoretical plates of the sec-butanol azeotropic rectification tower is 60, and the feed inlet is arranged at the 30th theoretical plate place, and the sec-butanol azeotropic rectification tower The operating conditions of the butanol azeotropic distillation tower are: normal pressure, tower top temperature 90°C, the top of the sec-butanol azeotropic rectification tower is a mixture of sec-butyl acetate, sec-butanol and water, which enters sec-butanol after condensation Alcohol azeotropic distillation tower top reflux tank, the oil phase after stratification is refluxed...

Embodiment 2

[0041] The sec-butyl acetate raw material is mixed with water according to the mass ratio of 1:10 and sent to the hydrolysis reactor, and reacted at a pressure of 1.5MPa and a temperature of 150°C to obtain sec-butyl alcohol, water, acetic acid and sec-butyl acetate Mixture; The reacted mixture is sent to the sec-butanol azeotropic rectification tower for separation, and the number of theoretical plates of the sec-butanol azeotropic rectification tower is 75, and the feed inlet is arranged at the 37th theoretical plate place, and the sec-butanol azeotropic rectification tower The operating conditions of the butanol azeotropic distillation tower are: normal pressure, tower top temperature 110°C, the top of the sec-butanol azeotropic rectification tower is a mixture of sec-butyl acetate, sec-butanol and water, which enters sec-butanol after condensation Alcohol azeotropic distillation tower top reflux tank, the oil phase after stratification is refluxed with a mixture of sec-buty...

Embodiment 3

[0043] The sec-butyl acetate raw material is mixed with water according to the mass ratio of 1:1 and sent to the hydrolysis reactor, and reacted at a pressure of 0.6 MPa and a temperature of 60° C. to obtain sec-butyl alcohol, water, acetic acid and sec-butyl acetate Mixture; The mixture after the reaction is sent into the sec-butanol azeotropic rectification tower to separate, and the number of theoretical plates of the sec-butanol azeotropic rectification tower is 45, and the feed inlet is arranged at the 23rd theoretical plate place, and the sec-butanol azeotropic rectification tower The operating conditions of the butanol azeotropic distillation tower are: normal pressure, tower top temperature 60°C, the top of the sec-butanol azeotropic rectification tower is a mixture of sec-butyl acetate, sec-butanol and water, which enters sec-butanol after condensation Alcohol azeotropic distillation tower top reflux tank, the oil phase after stratification is refluxed with a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com