Solar cell back panel base material, method for preparing same and solar cell back panel

A technology for solar cells and back sheets, applied in the field of solar back sheets, can solve the problems of water vapor barrier capability, thermal stability and mechanical properties that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

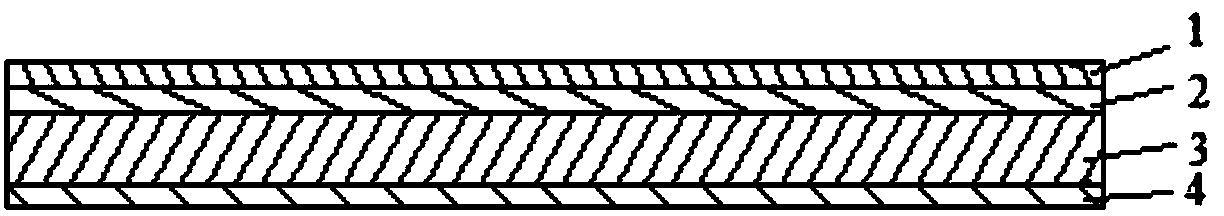

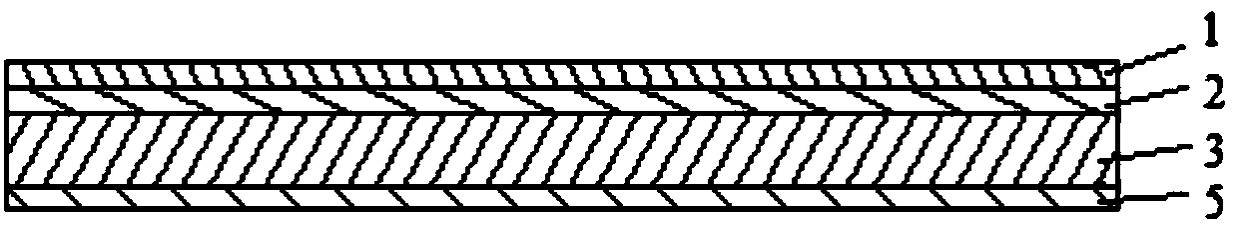

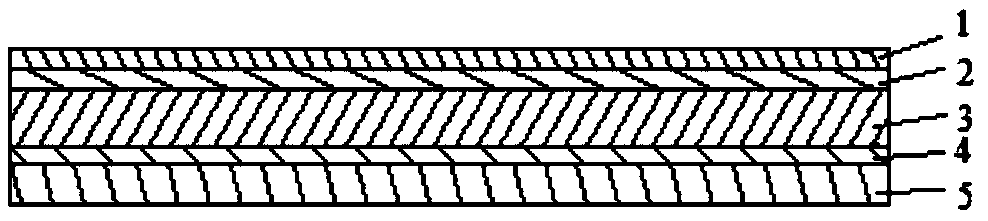

Image

Examples

Embodiment 1

[0064] Mix 600g of polyethylene, 300g of polyethylene terephthalate, and 100g of ethylene-ethyl acetate copolymer-g-maleic anhydride, and then prepare a solar battery backsheet by biaxially stretching a film as a core material layer Substrate.

Embodiment 2

[0066] Mix 500g of polypropylene, 300g of polybutylene terephthalate, 50g of polyolefin elastomer, 100g of polypropylene-g-maleic anhydride, and 250g of talcum powder, and then prepare it by casting a film as the core layer Solar cell backsheet substrate.

Embodiment 3

[0068] Ethylene-propylene copolymer 850g, polyethylene 2,6-naphthalate 100g, EPDM rubber 40g, ethylene-methacrylate copolymer-g-glycidyl methacrylate 10g are mixed, Then, the solar battery back sheet base material is prepared by uniaxially stretching the film to be used as the core material layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com