High-dispersion graphene solution prepared by virtue of one-step method and preparation method of high-dispersion graphene solution

A graphene solution, high dispersion technology, applied in the direction of coating, etc., can solve the problems of poor dispersion of graphene and polymer, discount of excellent performance of graphene, application restrictions, etc., and achieve convenient method, low cost and good applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

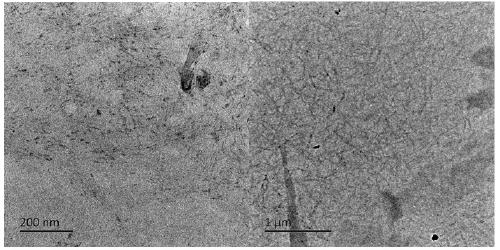

Image

Examples

Embodiment 1

[0039] One-step preparation of highly dispersed graphene solution is characterized in that it includes cellulose nanocrystal / graphene flake suspension; wherein, graphene flake and cellulose nanocrystal suspension in cellulose nanocrystal / graphene flake suspension The mass ratio is 1-3:100.

[0040] The modifier nanocellulose is cellulose nanocrystal / graphene flake suspension, the amount of dry matter after the two are blended ranges from 20.2-20.6g, and its preparation method is: treat with sulfuric acid with a concentration of 64% Microcrystalline cellulose Microcrystalline cellulose, proportioning microcrystalline cellulose: H 2 SO 4 =1g: 9.8ml, add a certain amount of flake graphene material and microcrystalline cellulose in proportion to mix with concentrated sulfuric acid, the acid hydrolysis temperature is 45 ℃, the time is 60min-120min; add deionized water to stop the acid hydrolysis reaction, then Centrifugal washing is carried out at a centrifugal speed of 4000 rpm ...

Embodiment 2

[0047] One-step preparation of highly dispersed graphene solution is characterized in that it includes cellulose nanocrystal / graphene flake suspension; wherein, graphene flake and cellulose nanocrystal suspension in cellulose nanocrystal / graphene flake suspension The mass ratio is 1-3:100.

[0048] The modifier nanocellulose is cellulose nanocrystal / graphene flake suspension, the amount of dry matter after the two are blended ranges from 20.2-20.6g, and its preparation method is: treat with sulfuric acid with a concentration of 64% Microcrystalline cellulose Microcrystalline cellulose, proportioning microcrystalline cellulose: H 2 SO 4 =1g: 9.8ml, add a certain amount of flake graphene material and microcrystalline cellulose in proportion to mix with concentrated sulfuric acid, the acid hydrolysis temperature is 45 ℃, the time is 60min-120min; add deionized water to stop the acid hydrolysis reaction, then Centrifugal washing is carried out at a centrifugal speed of 4000 rpm fo...

Embodiment 3

[0055] One-step preparation of highly dispersed graphene solution is characterized in that it includes cellulose nanocrystal / graphene flake suspension; wherein, graphene flake and cellulose nanocrystal suspension in cellulose nanocrystal / graphene flake suspension The mass ratio is 1-3:100.

[0056] The modifier nanocellulose is cellulose nanocrystal / graphene flake suspension, the amount of dry matter after the two are blended ranges from 20.2-20.6g, and its preparation method is: treat with sulfuric acid with a concentration of 64% Microcrystalline cellulose Microcrystalline cellulose, proportioning microcrystalline cellulose: H 2 SO 4 =1g: 9.8ml, add a certain amount of flake graphene material and microcrystalline cellulose in proportion to mix with concentrated sulfuric acid, the acid hydrolysis temperature is 45 ℃, the time is 60min-120min; add deionized water to stop the acid hydrolysis reaction, then Centrifugal washing is carried out at a centrifugal speed of 4000 rpm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com