A feni-based laser cladding doped tungsten carbide/chromium carbide composite enhanced high temperature and wear resistance coating and its preparation method

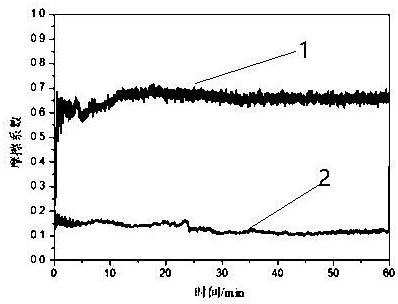

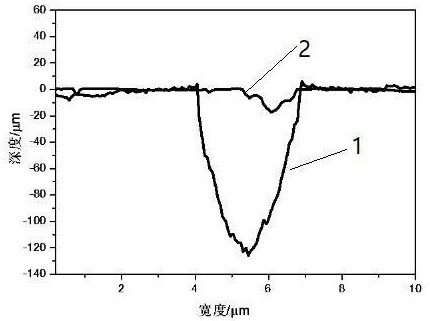

A laser cladding and wear-resistant coating technology, applied in the direction of coating, solid-state diffusion coating, metal material coating process, etc. Good matching effect, low friction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Another aspect of the present invention provides a FeNi-based laser cladding doped WC / Cr 2 C 3 A method for preparing a composite strengthened high-temperature wear-resistant coating, the preparation method comprising the following steps:

[0029] (1) Polish the surface of the substrate, the surface roughness Ra<0.4, after the treatment, the surface to be treated is preheated under inert gas, and the preheating temperature is 60-220°C;

[0030] (2) performing surfacing treatment on the surface of the substrate treated in step (1) to obtain a surfacing layer;

[0031] (3) Carry out laser cladding treatment on the surfacing layer to obtain a double-layer transitional gradient cladding layer, wherein the chemical composition and mass fraction of the powder used in the first cladding layer are: 10-15wt.%WC, 0.5-1.2wt .%C, 2.0-4.0wt.%Si, 15-30wt.%Ni, 10-25wt.%Cr 2 C 3 , 11.0-18.0wt.%Cr, 0.5-1.5wt.%Zr, 0.07-0.15wt.%Y, the balance is Fe; the chemical composition and mass f...

Embodiment 1

[0043] The invention provides a FeNi-based laser cladding doped tungsten carbide / chromium carbide composite strengthened high-temperature and wear-resistant coating, which includes a surfacing layer, a first cladding layer, a second Cladding layer, vulcanization layer; the chemical composition and mass fraction of the powder used in the first cladding layer are: 10wt.%WC, 0.5wt.%C, 2.0wt.%Si, 15wt.%Ni, 10wt.%Cr 2 C 3 , 11.0wt.%Cr, 0.5wt.%Zr, 0.07wt.%Y, the balance is Fe; the chemical composition and mass fraction of the powder used in the second cladding layer are: 30wt.%WC, 0.5wt.%C, 2.0wt.%Si, 15wt.%Ni, 10wt.%Cr 2 C 3 , 11.0wt.%Cr, 1.5wt.%Zr, 0.07wt.%Y, 2.0wt.%Mo, and the balance is Fe.

[0044] The chemical composition and mass fraction of the powder used in the surfacing layer are 0.1wt.%C, 0.2wt.%Si, 2.0wt.%Cr, 14wt.%Ni, 0.1wt.%Zr, 0.03wt.%Y, 0.06wt .%S, 0.046wt.%, the balance is Fe.

[0045] The sulfide layer is FeS, MoS 2 Solid lubricant layer.

[0046] The prepa...

Embodiment 2

[0053] The invention provides a FeNi-based laser cladding doped tungsten carbide / chromium carbide composite strengthened high-temperature and wear-resistant coating, which includes a surfacing layer, a first cladding layer, a second Cladding layer, vulcanization layer; the chemical composition and mass fraction of the powder used in the first cladding layer are: 1.2wt.%C, 4.0wt.%Si, 20wt.%Ni, 25wt.%Cr 2 C 3 , 18.0wt.%Cr, 14wt.%Ni, 1.5wt.%Zr, 0.10wt.%Y, the balance is Fe; the chemical composition and mass fraction of the powder used in the second cladding layer are: 20wt.%WC, 1.2wt.%C, 4.0wt.%Si, 20wt.%Ni, 15wt.%Cr 2 C 3 , 11.0wt.%Cr, 1wt.%Zr, 0.15wt.%Y, 15wt.%Mo, and the balance is Fe.

[0054] The chemical composition and mass fraction of the powder used in the surfacing layer are 0.2wt.%C, 0.4wt.%Si, 3.2wt.%Cr, 25wt.%Ni, 0.3wt.%Zr, 0.06wt.%Y, 0.02wt .% S, 0.030wt.% P, the balance being Fe.

[0055] The sulfide layer is FeS, MoS 2 Solid lubricant layer.

[0056] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com