Preparation method and application of composite material for treating synthetic dye wastewater

A technology for synthesizing dyes and composite materials, which is applied in the field of composite material preparation to achieve the effects of less pollution, energy saving, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

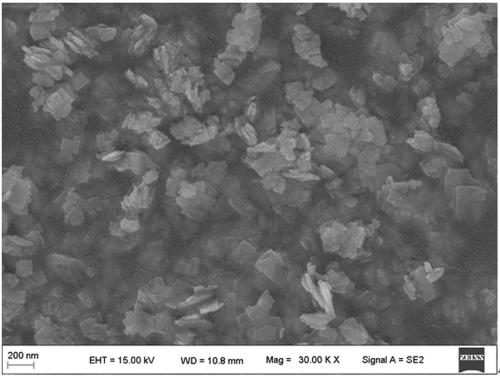

[0038] a kind of Ag 2 MoO 4 The preparation method of the visible light catalytic composite material comprises the following steps (x:y=0.5).

[0039] Step 1. 1mmol ammonium tungstate (H 40 N 10 o 41 W 12 ·6H 2 (0) and 10 mmol of p-aminophenol were added to 10 ml of deionized water, and the solution was ultrasonically dispersed for about 10 min, and the solution was poured into the flask at the lower end of the serpentine condenser, stirred for 30 min, and the temperature of the water area was controlled at 60 ° C to obtain solution A .

[0040] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in 30ml ethanol / water solution, the volume ratio of ethanol to deionized water is 1:10, control the pH of the solution to 5, stir until completely dissolved, and obtain solution B.

[0041] Step 3. Slowly pour solution B into solution A, stir for 3h, add 60mmol sodium dodecylbenzenesulfonate at the same time, filter the resulting suspension with suction, wash wi...

Embodiment 2

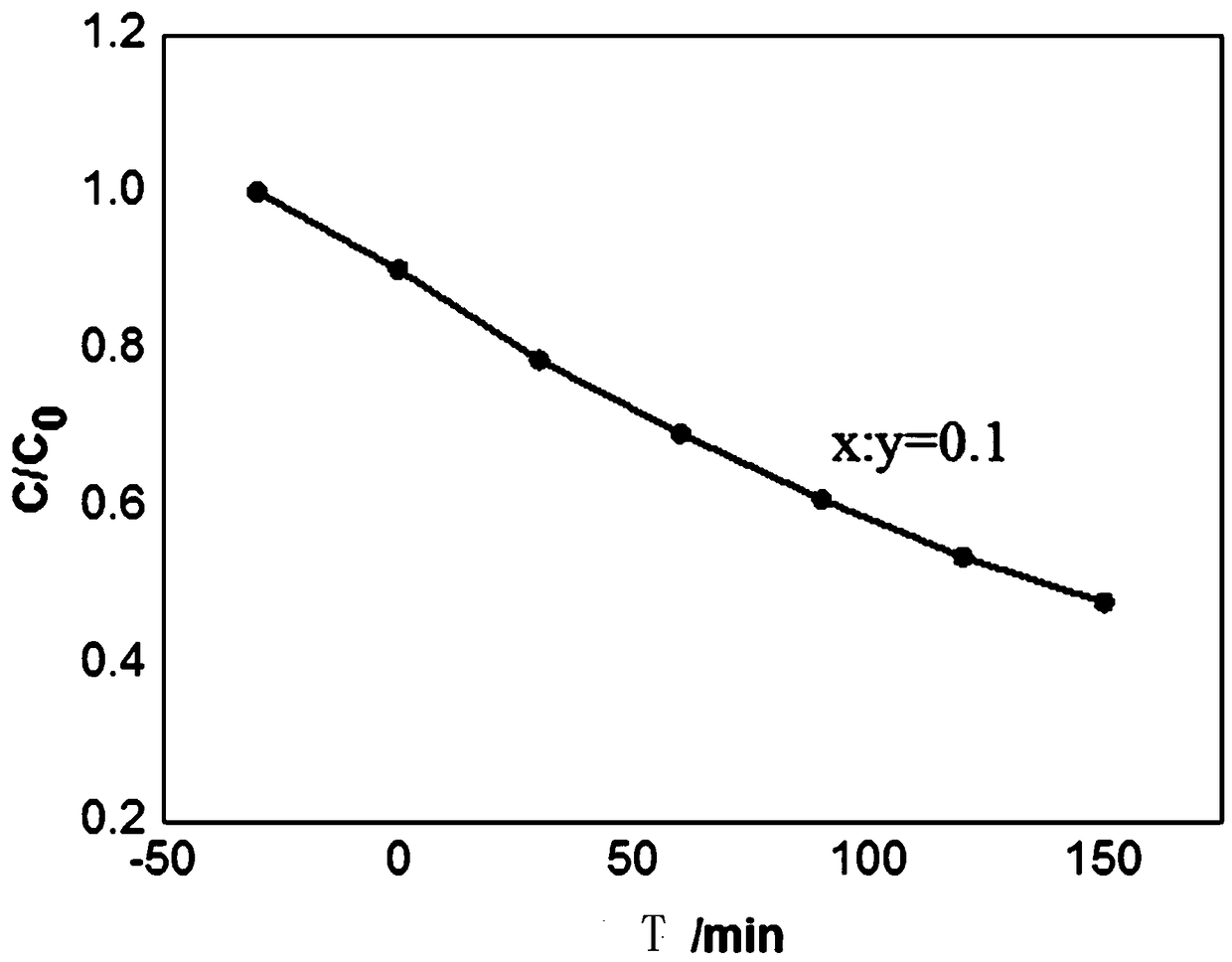

[0047] a kind of Ag 2 MoO 4 The preparation method of the visible light catalytic composite material comprises the following steps: x:y=0.1.

[0048] Step 1. 1mmol ammonium tungstate (H 40 N 10 o 41 W 12 ·6H 2 (0) and 10 mmol of p-aminophenol were added to 10 ml of deionized water, and the solution was ultrasonically dispersed for about 10 min, and the solution was poured into the flask at the lower end of the serpentine condenser, stirred for 30 min, and the temperature of the water area was controlled at 80° C. to obtain solution A .

[0049] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in a solution of 30ml ethanol and water, the volume ratio of ethanol and deionized water is 1:10, control the pH of the solution to 4, stir until completely dissolved, and obtain solution B.

[0050] Step 3. Slowly pour solution B into solution A, stir for 3 hours, add 12 mmol sodium dodecylbenzenesulfonate at the same time, filter the resulting suspension with s...

Embodiment 3

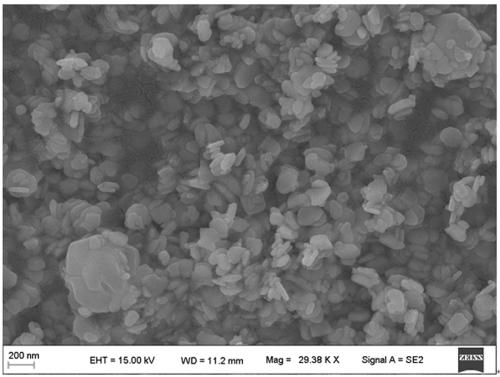

[0058] a kind of Ag 2 MoO 4 The preparation method of the visible light catalytic composite material comprises the following steps: x:y=0.6.

[0059] Step 1. 1mmol ammonium tungstate (H 40 N 10 o 41 W 12 ·6H 2 (0) and 10 mmol of p-aminophenol were added to 10 ml of deionized water, and the solution was ultrasonically dispersed for about 10 min, and the solution was poured into the flask at the lower end of the serpentine condenser, stirred for 30 min, and the temperature of the water area was controlled at 60 ° C to obtain solution A .

[0060] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in 30ml of ethanol / water solution, the volume ratio of ethanol to deionized water is 1:10, control the pH of the solution to 3, stir until completely dissolved, and obtain solution B.

[0061] Step 3. Slowly pour solution B into solution A, stir for 3h, add 72mmol sodium dodecylbenzenesulfonate at the same time, filter the resulting suspension with suction, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com