A non-ferrous metal mine flotation process

A technology for non-ferrous metals and mines, used in flotation, solid separation, etc., can solve the problems of increasing the amount of bubbles, the effect of foaming agents, and reducing the quality of flotation, to accelerate the flotation rate, reduce the strength, and accelerate the reaction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

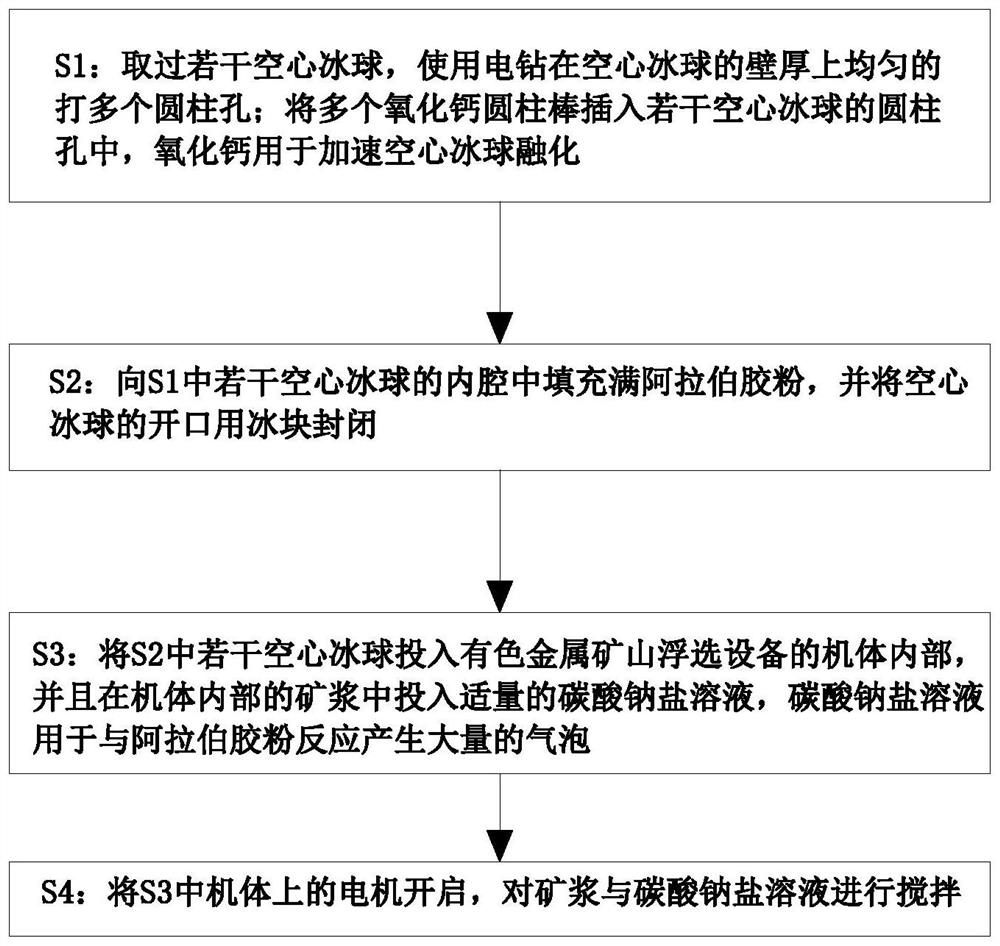

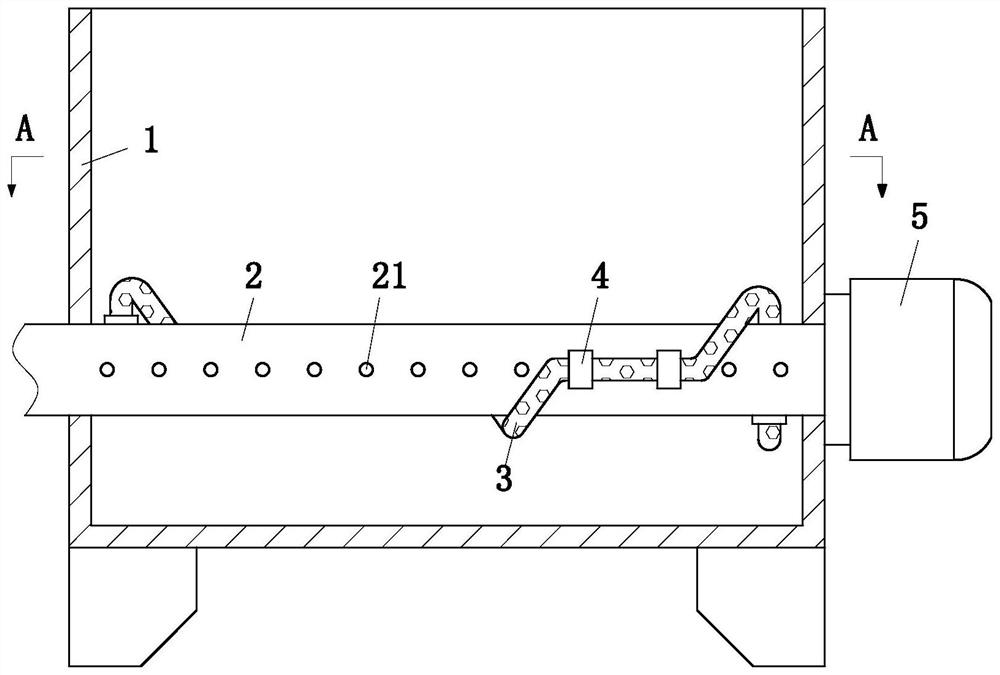

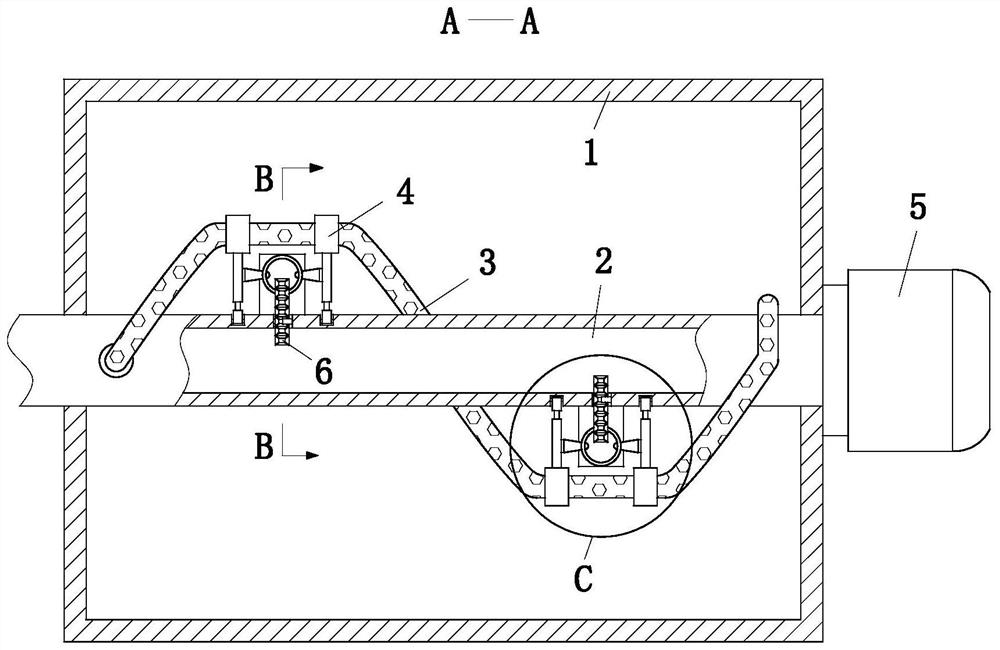

[0027] use Figure 1 to Figure 5 A kind of nonferrous metal mine flotation process of the present invention is described as follows.

[0028] Such as Figure 1 to Figure 5 Shown, a kind of non-ferrous metal mine flotation process of the present invention, this process comprises the steps:

[0029]S1: Take a number of hollow ice balls, use an electric drill to evenly drill multiple cylindrical holes on the wall thickness of the hollow ice balls; insert multiple calcium oxide cylindrical rods into the cylindrical holes of several hollow ice balls, and calcium oxide is used to accelerate the melting of the hollow ice balls; Multiple cylindrical holes reduce the structural strength of the hollow ice ball, which is convenient for the hollow ice ball to break when it collides with the slag; the calcium oxide cylindrical rod reacts with the water in the slurry to generate heat, which is conducive to accelerating the melting of the hollow ice ball. selection rate;

[0030] S2: Fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com