Ammonium thiocyanate-cetylpyridinium bromide-water system flotation separation method for gold

A technology of bromide cetylpyridine and ammonium thiocyanate, applied in the field of precious metal separation and purification, can solve the problems of environmental pollution, toxicity, low mass transfer rate, etc., achieves rapid separation and enrichment method, good application prospect, The effect of low separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

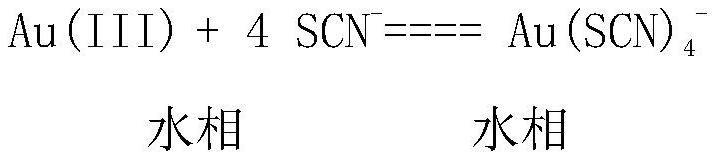

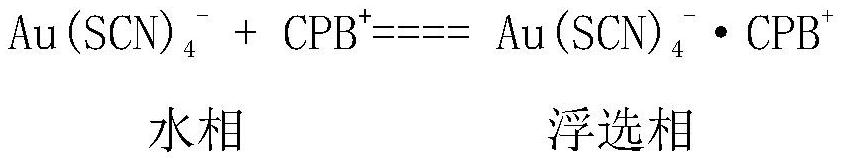

Method used

Image

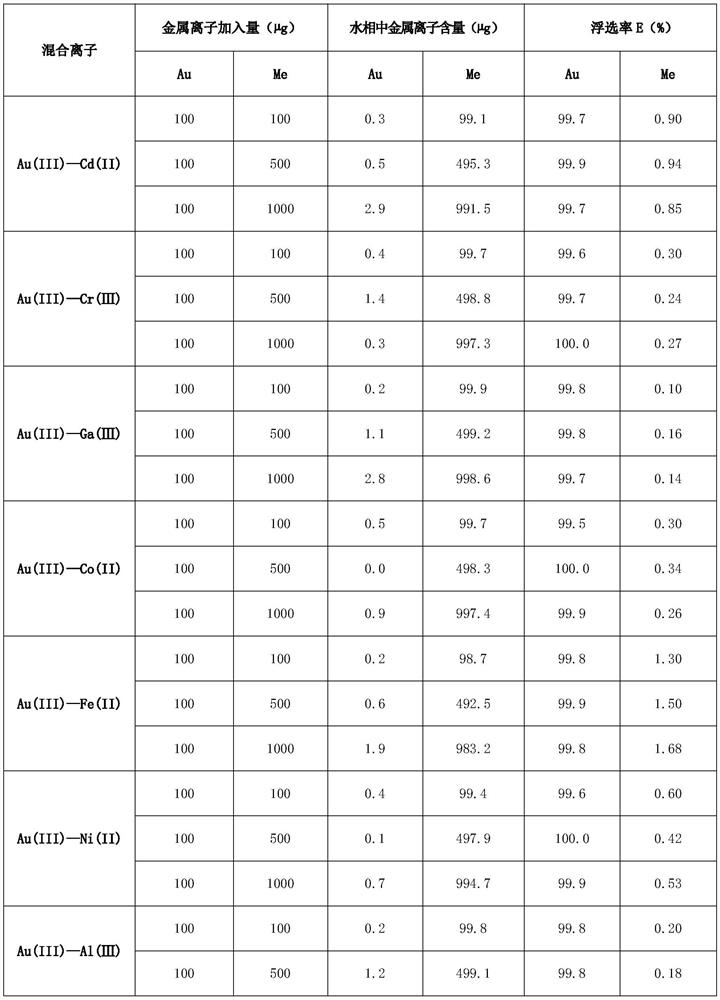

Examples

Embodiment 1

[0032] This embodiment provides the method for ammonium thiocyanate-cetylpyridinium bromide-water system flotation separation of gold, comprising the following steps:

[0033] (1) Add ammonium thiocyanate solution to the flotation solution, stir the solution until completely mixed to obtain mixed solution A;

[0034] (2) Add cetylpyridinium bromide solution to the mixed solution A to obtain the mixed solution B, add Clark-Lubes buffer dropwise to adjust the pH to 4.0, and stir until all the precipitates are separated out;

[0035] (3) Filter the mixed solution obtained in step (2), obtain the precipitate, transfer it to a beaker, add water and boil for 2-4 times, filter, and wash with water;

[0036] (4) Bake the precipitate obtained in step (3) at 200°C for 10 hours to obtain solid gold;

[0037] Wherein the relative concentration of ammonium thiocyanate in solution A is 2.0×10 -2 mol / L, the relative concentration of cetylpyridinium bromide in solution B is 4.0×10 -3 mol / L...

Embodiment 2

[0041] This embodiment provides the method for ammonium thiocyanate-cetylpyridinium bromide-water system flotation separation of gold, comprising the following steps:

[0042] (1) Add ammonium thiocyanate solution to the flotation solution, stir the solution until completely mixed to obtain mixed solution A;

[0043] (2) Add cetylpyridinium bromide solution to the mixed solution A to obtain the mixed solution B, add Clark-Lubes buffer dropwise to adjust the pH to 4.0, and stir until all the precipitates are separated out;

[0044] (3) Filter the solution obtained in step (2), obtain the precipitate, transfer it to a beaker, add water and boil for 2-4 times, filter, and wash with water;

[0045] (4) Bake the precipitate obtained in step (3) at 200°C for 10 hours to obtain solid gold;

[0046] Wherein the relative concentration of ammonium thiocyanate in solution A is 2.0×10 -2 mol / L, the relative concentration of cetylpyridinium bromide in solution B is 4.0×10 -3 mol / L.

[...

Embodiment 3

[0050] This embodiment provides the method for ammonium thiocyanate-cetylpyridinium bromide-water system flotation separation of gold, compared with Example 1, the difference is that the concentration of the ammonium thiocyanate in the A solution 1.0×10 -2 mol / L, the concentration of said cetylpyridinium bromide in solution B is 2.0×10 -3 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com