Method for synchronously separating liquiritin and liquiritin apioside from liquorice

A technology of glycyrrhizin apiose and synchronous separation, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc. Complex chemical composition and other problems, to achieve the effect of fast adsorption, easy industrial amplification, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Extraction: Take 0.5kg of licorice powder, add 5L of methanol with a volume fraction of 85%, heat and reflux for extraction for 2 hours, filter, add 5L of 85% methanol to the filter residue, heat and reflux for 2 hours, filter, and combine the two extracts , extraction and hydraulic concentration to recycle the organic solvent, add water to the raffinate, and mix well to make the raffinate concentration 10g / L to obtain the intermediate product A.

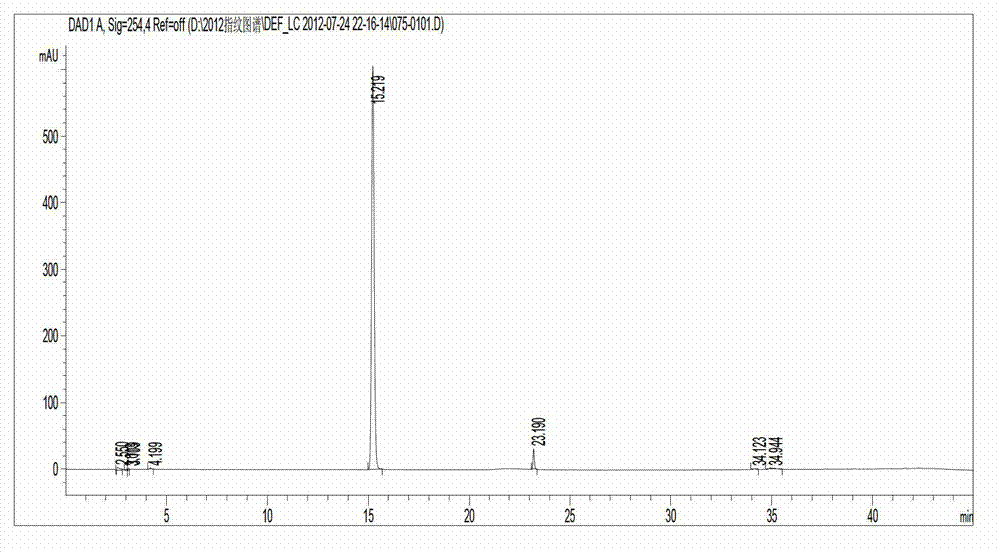

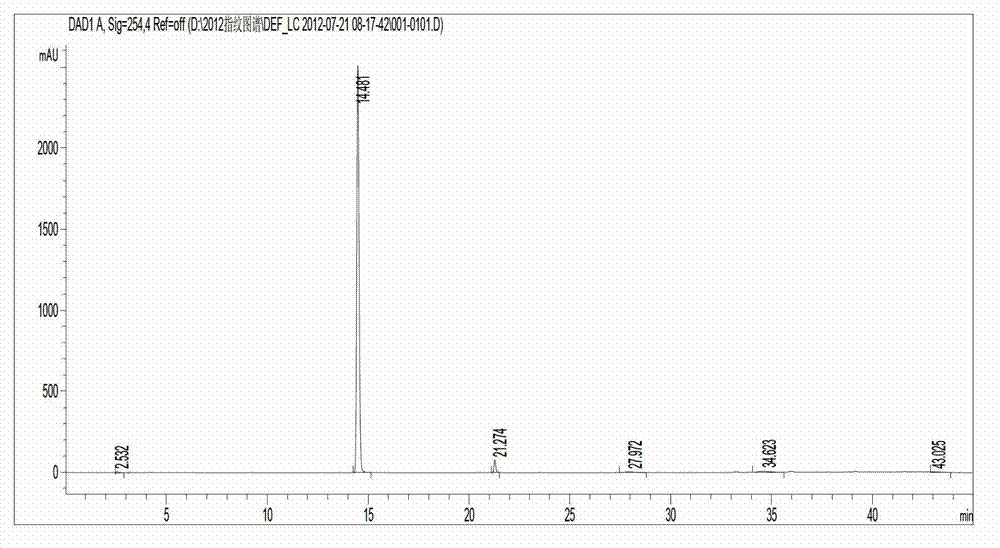

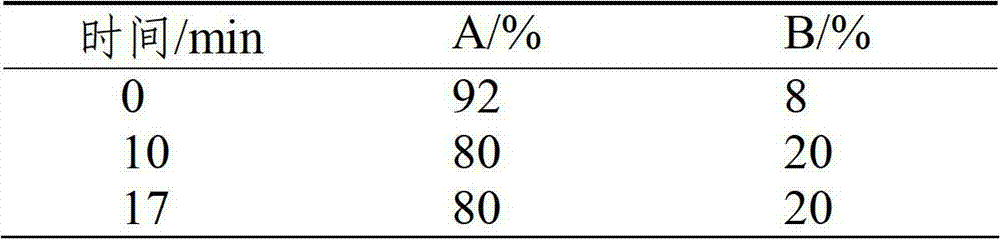

[0036] (2) Primary separation and purification of the resin column: the intermediate product A passes through the D101 resin column filled with 3-stage serial series treated according to the conventional method at a flow rate of 3BV / h, and is dynamically adsorbed to breakthrough, wherein each stage of the D101 resin column The diameter-to-height ratio is 1:10; the resin column is eluted with water with a flow rate of 8BV / h to remove water-soluble impurities, and the water analysis solution is discarded; the tandem resin co...

Embodiment 2

[0042] (1) Extraction: Take 1kg of licorice powder, add 10L of 75% methanol, extract by ultrasonic for 2h, filter, add 10L of 75% methanol to the filter residue, extract by ultrasonic for 2h, filter, combine the two extracts, and decompress the extract Concentrate and recover the organic solvent, add water to the raffinate, and mix well to make the concentration 8g / L, and then intermediate product A is obtained.

[0043] (2) Primary separation and purification of the resin column: the intermediate product A passes through the AB-8 resin column filled with a diameter-to-height ratio of 1:8 at a flow rate of 5BV / h, 4 stages are connected in series, and are dynamically adsorbed to breakthrough. The diameter-to-height ratio of the AB-8 resin column is 1:6; the resin column is eluted with water with a flow rate of 8BV / h to remove water-soluble impurities, and the water analysis solution is discarded; wash with 70% ethanol at a speed of 5BV / h The tandem resin column after impurity i...

Embodiment 3

[0047] (1) Extraction: Take 2kg of licorice powder, add 20L of 70% ethanol, extract by ultrasonic for 1h, filter, add 20L of 70% ethanol to the filter residue, ultrasonically for 1h, filter, combine the two extracts, and concentrate the extract under reduced pressure Recover the organic solvent, add water to the raffinate, and mix well to make the concentration 12g / L to obtain the intermediate product A.

[0048] (2) Primary separation and purification of the resin column: the intermediate product A passes through the D101 resin column filled with the conventional method at a flow rate of 8BV / h, 5 stages in series, the diameter-to-height ratio is 1:10, and is dynamically adsorbed to breakthrough , the resin column was eluted with water at a flow rate of 10BV / h to remove water-soluble impurities, and the water analysis solution was discarded. Use 60% ethanol to elute the tandem resin column after washing at 6BV / h, collect the eluate until the eluate is colorless, concentrate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com