Carbon nano-tube purification method

A technology of carbon nanotubes and purification methods, applied in the directions of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of high cost, low efficiency, high difficulty, etc., and achieve fast purification speed, high purity, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

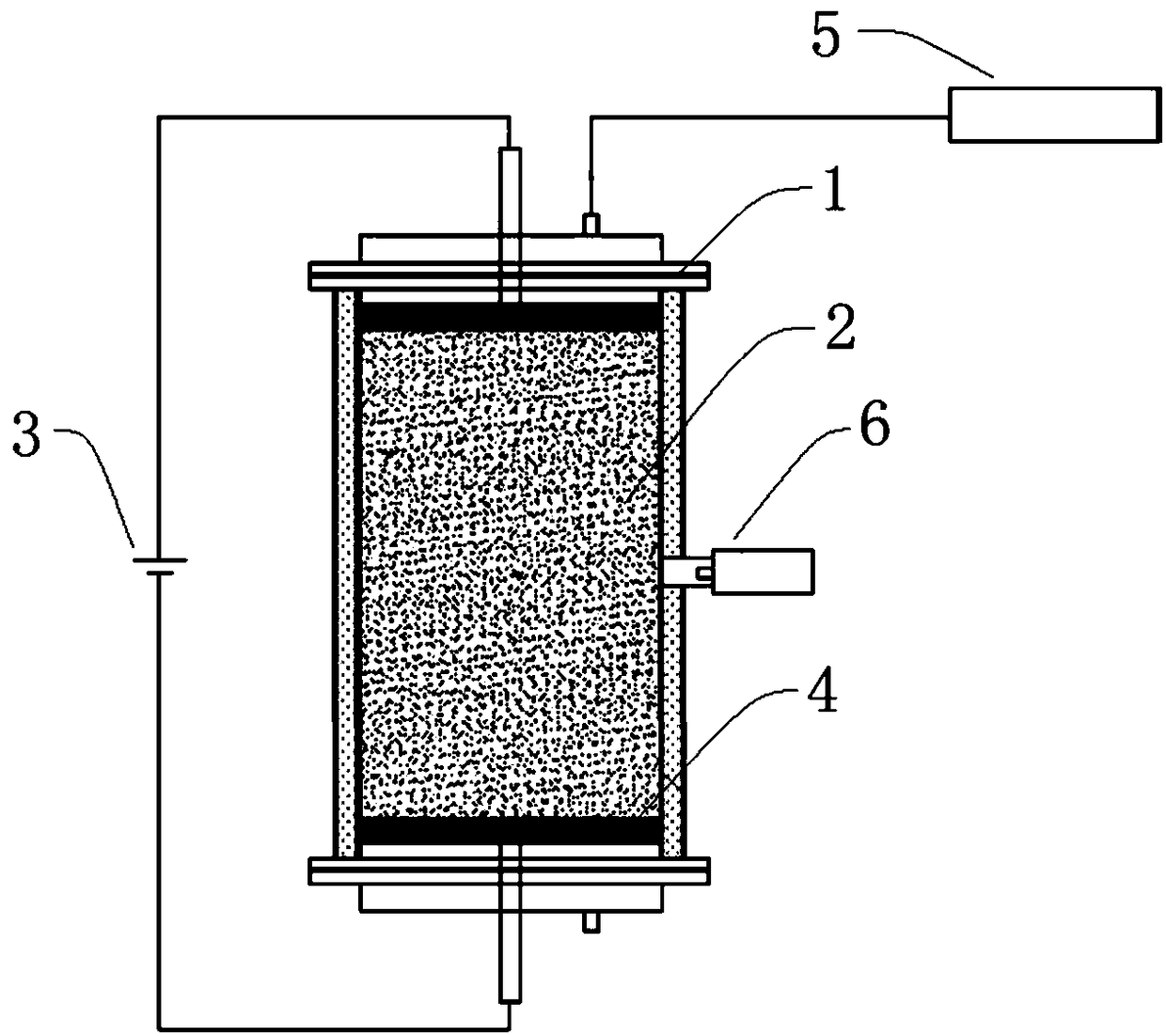

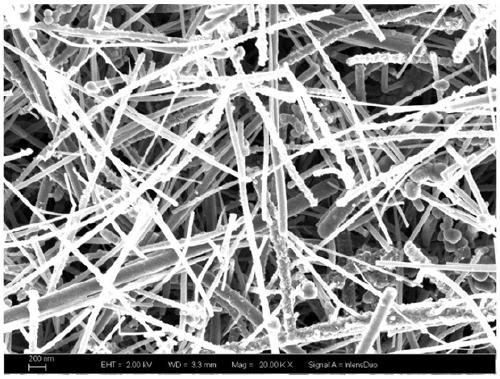

[0026] This embodiment is used for the purification of whisker-shaped multi-walled carbon nanotubes, and the specific operation process is as follows:

[0027] S 1 , pressing 500g of whisker-shaped multi-walled carbon nanotubes into an electric heating element;

[0028] S 2 , put the compacted electric heating element into a quartz container, and connect it with two graphite electrodes;

[0029] S 3 , vacuuming, argon, repeat the operation 3 times to completely remove the air; and then vacuumize to keep the vacuum degree of the quartz container at 9.0×10 -8 mbar;

[0030] S 4 , adopt the pulse electric heating method, pass in a current of 1A, and the current pulse will generate a Joule heat shock within 1s through the graphite electrode, and the temperature of the carbon nanotubes in the electric heating element will rise sharply to 500°C. The iron element and iron oxide on the surface are oxidized to ferric chloride, and ferric chloride (boiling point 315°C) is gasified...

Embodiment 2

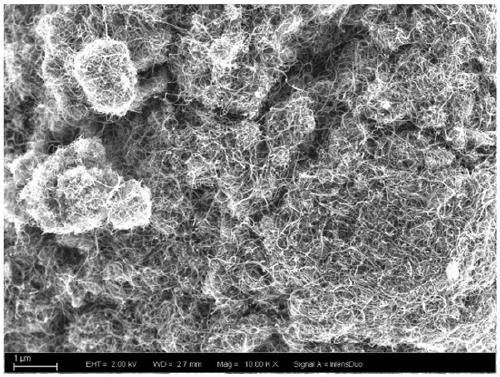

[0033] This embodiment is used for the purification of pompom-shaped multi-walled carbon nanotubes, and the specific operation process is as follows:

[0034] S 1 , pressing 500g of pompom-shaped multi-walled carbon nanotubes into an electric heating element;

[0035] S 2 , put the compacted electric heating element into a quartz container, and connect it with two graphite electrodes;

[0036] S 3 , vacuuming, argon, repeat the operation 3 times to completely remove the air; and then vacuumize to keep the vacuum degree of the quartz container at 9.0×10 -8 mbar;

[0037] S 4 , using the pulse electric heating method, the current 2A is passed through, the current pulse passes through the graphite electrode to generate a Joule thermal shock within 1s, the temperature of the carbon nanotubes in the electric heating element rises sharply to 1500 ° C, at this time, chlorine gas is passed into the carbon nanotubes Iron element, nickel element, ferric oxide, nickel oxide, alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com