Preparation method of high-performance carboxyl functionalized poly (arylene ether nitrile)

A carboxyl-functionalized, polyarylene ether nitrile technology, applied in the field of polymer materials, can solve the problems of insufficient diversification of restricted functions in synthesis, processing and application, and achieve functional diversity, excellent thermal stability and thermo-oxidative stability. the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

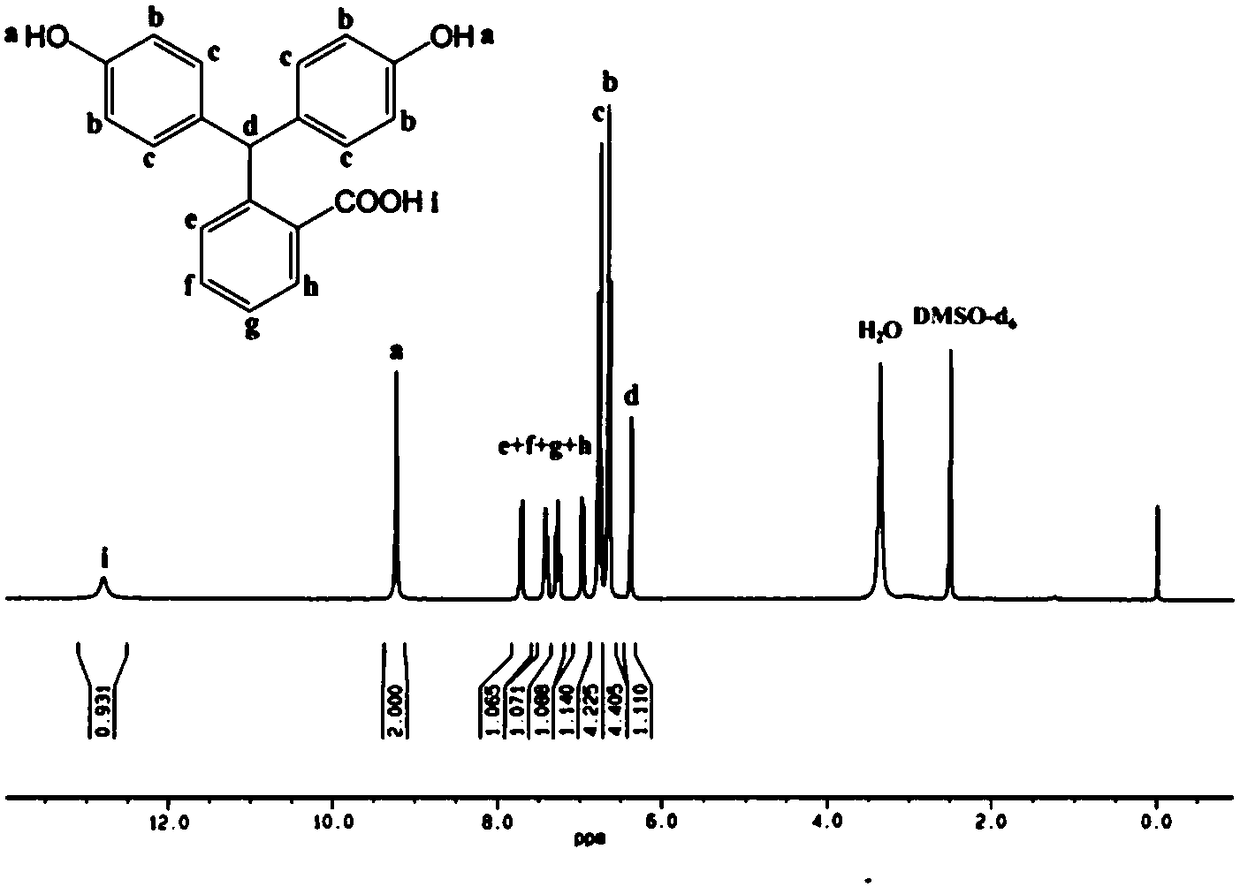

[0033] 1) Preparation of carboxyl-containing monomer phenolphthalein:

[0034] Prepare zinc powder, phenolphthalein and sodium hydroxide according to the molar ratio of 1:0.32:3.76, now prepare sodium hydroxide into a sodium hydroxide solution with a mass fraction of 6.25%, and then add phenolphthalein and zinc powder to the above sodium hydroxide solution , because phenolphthalein transforms into a quinone structure in an alkaline solution, the above mixed solution is purple. Place the mixed solution in a constant temperature water bath at 60°C and maintain mechanical stirring at 600rpm until the purple color disappears completely, then slowly add dilute hydrochloric acid to obtain a white precipitate, wash it repeatedly with deionized water until the washed out liquid is neutral, and finally put The white precipitate was dried in a vacuum oven at 80°C for 72 hours to obtain the carboxyl-containing monomer phenolphthalein;

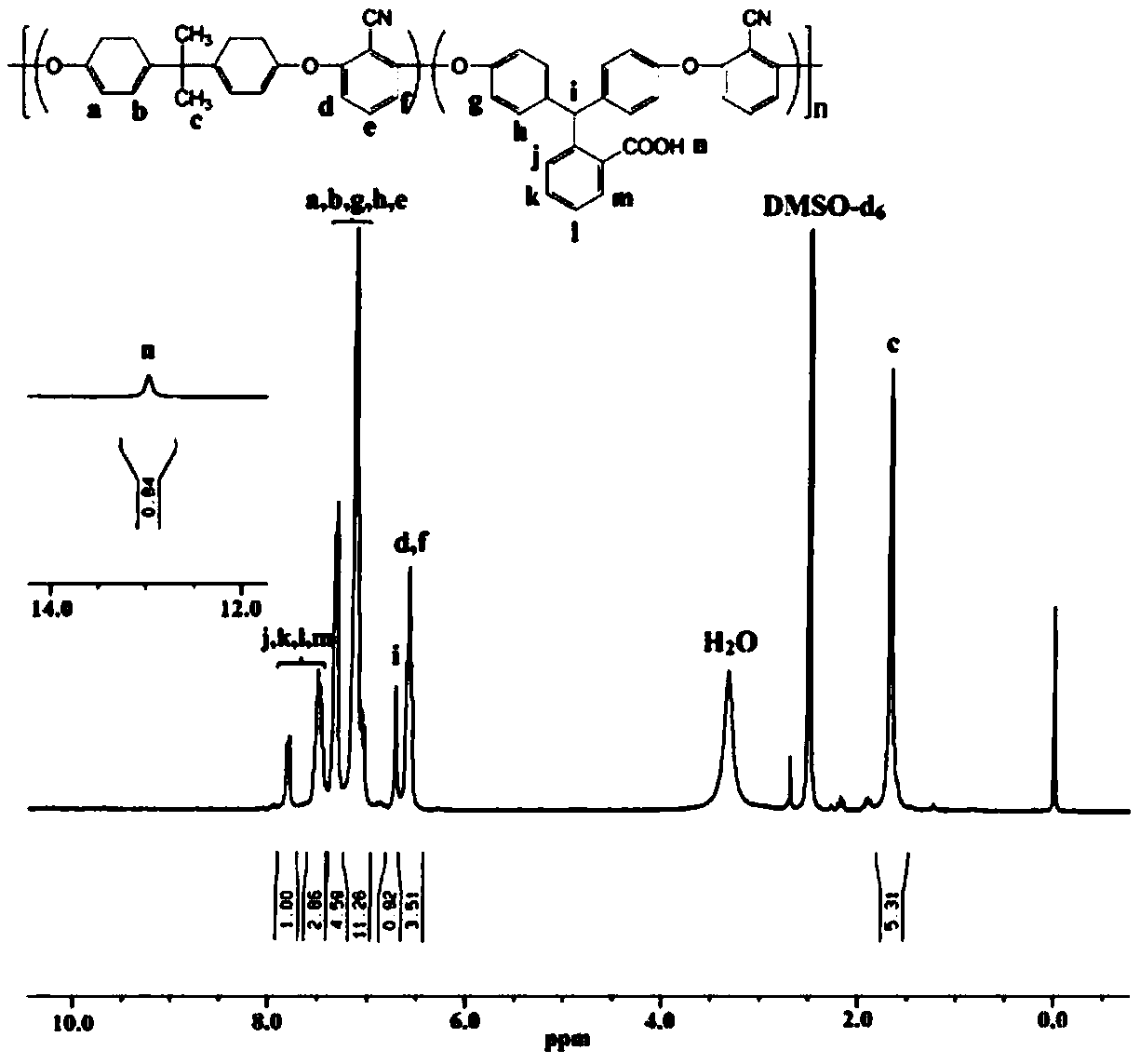

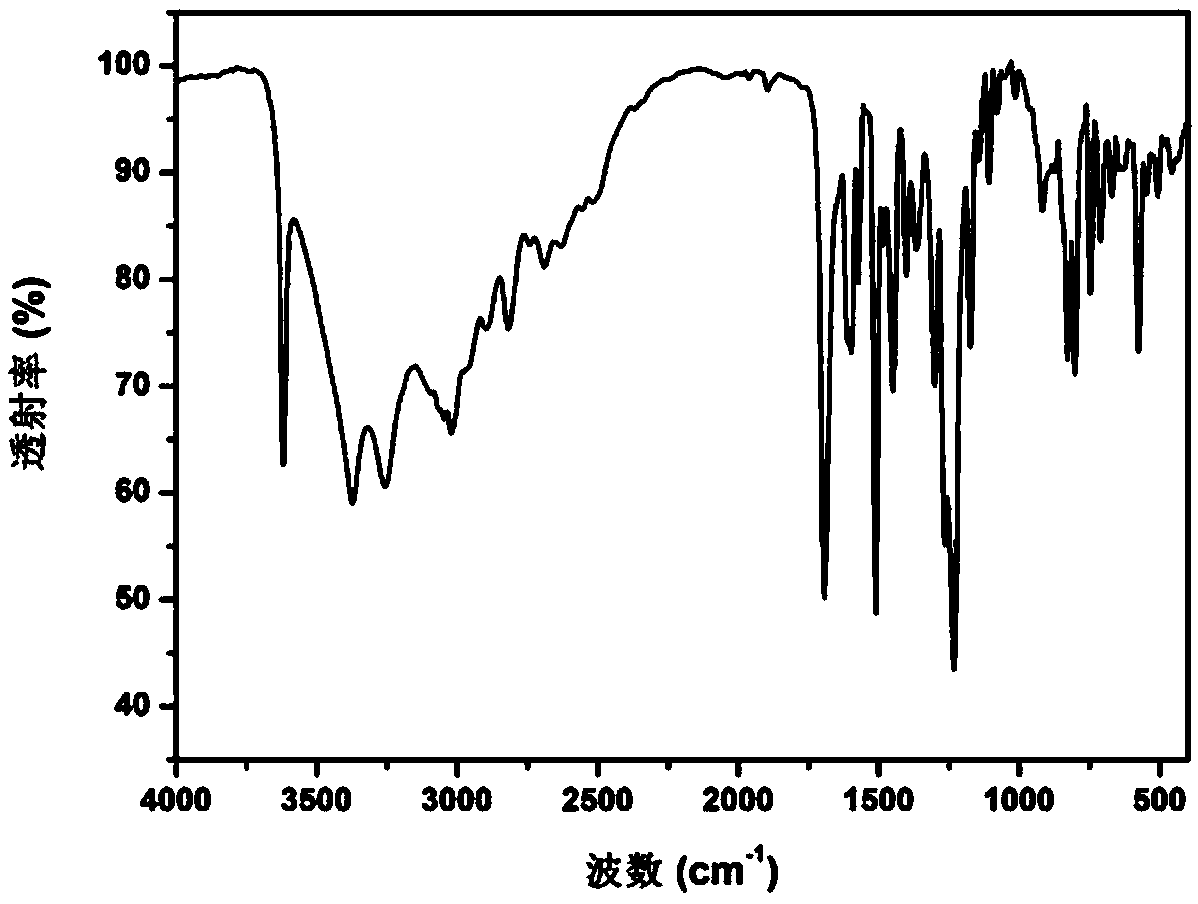

[0035] 2) Preparation of carboxyl functionalized p...

Embodiment 2

[0038] 1) Preparation of carboxyl-containing monomer phenolphthalein:

[0039] Prepare zinc powder, phenolphthalein and sodium hydroxide according to the molar ratio of 1:0.32:3.76, now prepare sodium hydroxide into a sodium hydroxide solution with a mass fraction of 6.25%, and then add phenolphthalein and zinc powder to the above sodium hydroxide solution , because phenolphthalein transforms into a quinone structure in an alkaline solution, the above mixed solution is purple. Place the mixed solution in a constant temperature water bath at 60°C and maintain mechanical stirring at 600rpm until the purple color disappears completely, then slowly add dilute hydrochloric acid to obtain a white precipitate, wash it repeatedly with deionized water until the washed out liquid is neutral, and finally put The white precipitate was dried in a vacuum oven at 80°C for 72 hours to obtain the carboxyl-containing monomer phenolphthalein;

[0040] 2) Preparation of hydroquinone and phenolph...

Embodiment 3

[0043] 1) Preparation of carboxyl-containing monomer phenolphthalein:

[0044] Prepare zinc powder, phenolphthalein and sodium hydroxide according to the molar ratio of 1:0.32:3.76, now prepare sodium hydroxide into a sodium hydroxide solution with a mass fraction of 6.25%, and then add phenolphthalein and zinc powder to the above sodium hydroxide solution , because phenolphthalein transforms into a quinone structure in an alkaline solution, the above mixed solution is purple. Place the mixed solution in a constant temperature water bath at 60°C and maintain mechanical stirring at 600rpm until the purple color disappears completely, then slowly add dilute hydrochloric acid to obtain a white precipitate, wash it repeatedly with deionized water until the washed out liquid is neutral, and finally put The white precipitate was dried in a vacuum oven at 80°C for 72 hours to obtain the carboxyl-containing monomer phenolphthalein;

[0045] 2) Preparation of resorcinol and phenolphth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com