Toughened modified nylon

A kind of toughening modification, nylon technology, applied in the field of polymer material application, nylon modification, can solve the problems of deteriorating processing performance and heat resistance, damage to material strength and rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 50 parts of thermoplastic elastomer POE; 6 parts of mixture of bismaleic acid and maleic anhydride; 50 parts of homopolypropylene.

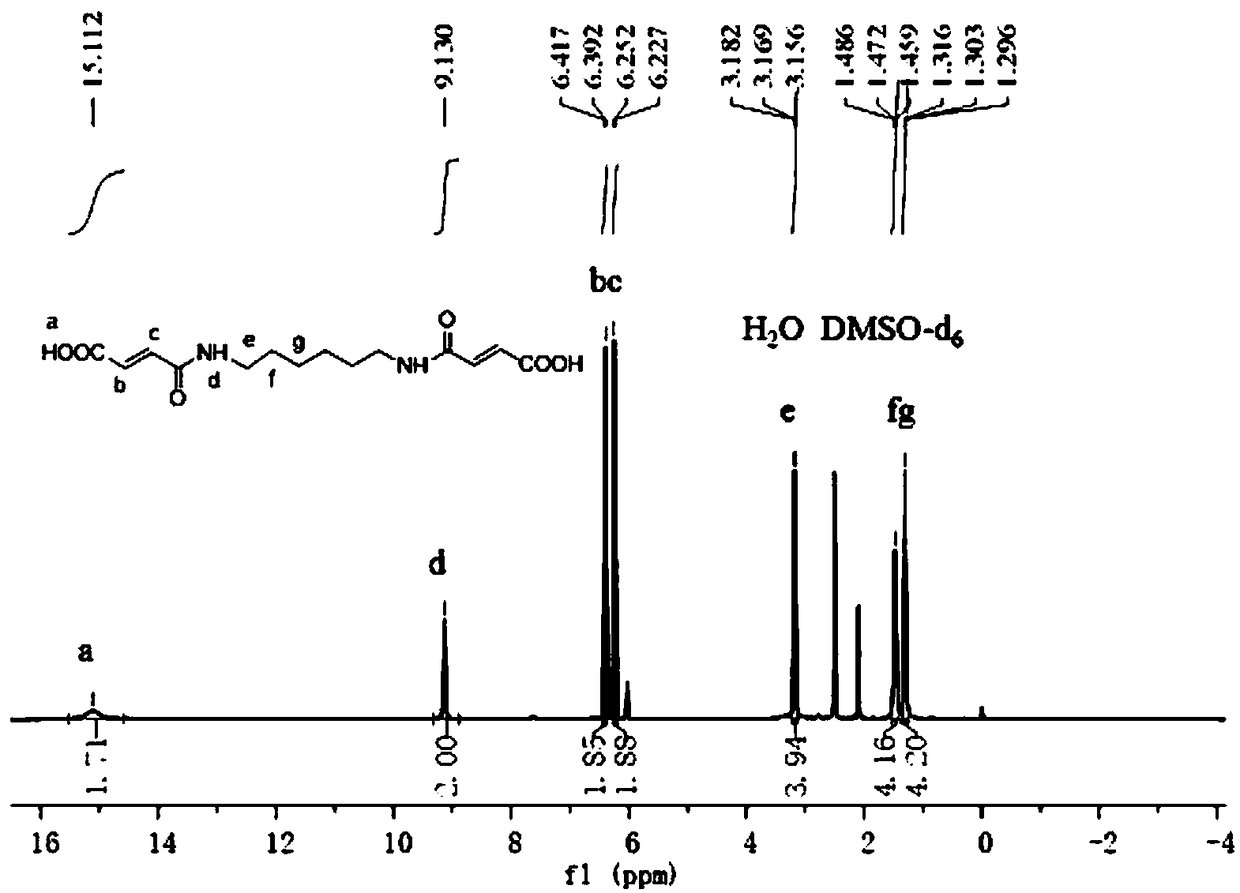

[0024] First, maleic anhydride and hexamethylenediamine with a molar ratio of 2.2:1 were dissolved in acetone solution at room temperature, stirred thoroughly, and after they were completely dissolved, the solution was slowly poured into the acetone solution of hexamethylenediamine, and Stir continuously for 60 min. After the reaction is completed, add the mixed solution into petroleum ether and stir continuously for 30 min. After suction filtration and drying, a mixture of dimaleyl diamic acid and maleic anhydride is obtained.

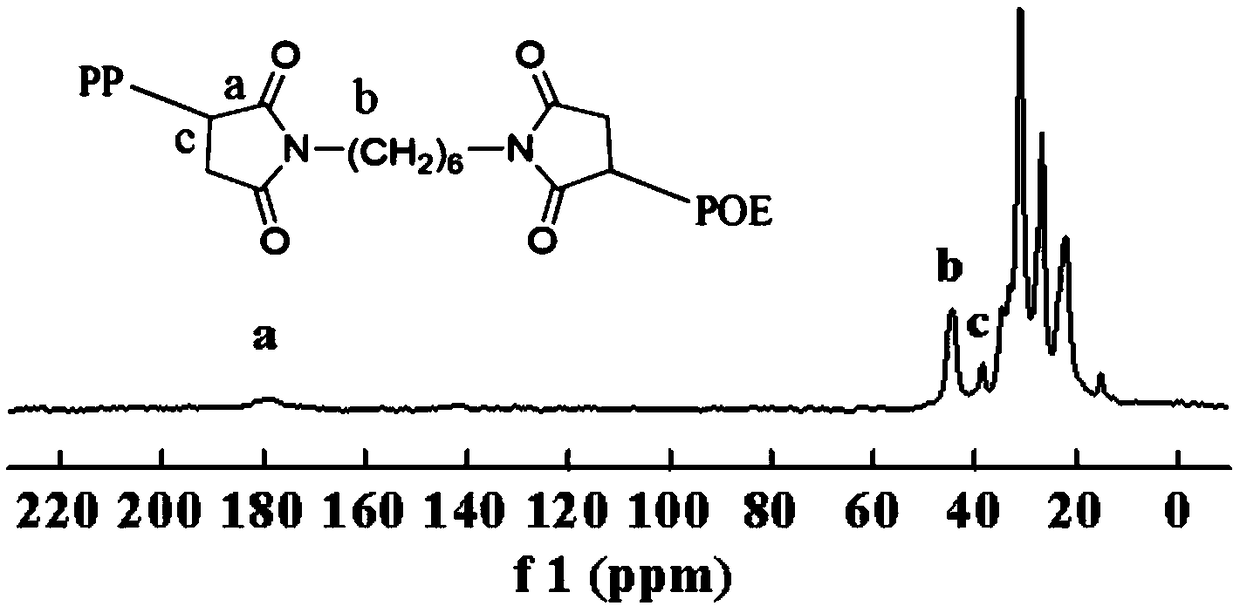

[0025] Dry 50 parts of thermoplastic elastomer POE, 50 parts of homopolypropylene PP, and 6 parts of the above-mentioned mixture of bismaleyl diamine acid and maleic anhydride in a blast oven at 80°C for 8 hours, and add 0.004 parts of diisopropyl peroxide Mix benzene evenly, melt and mix reaction in a twin-screw ...

Embodiment 2

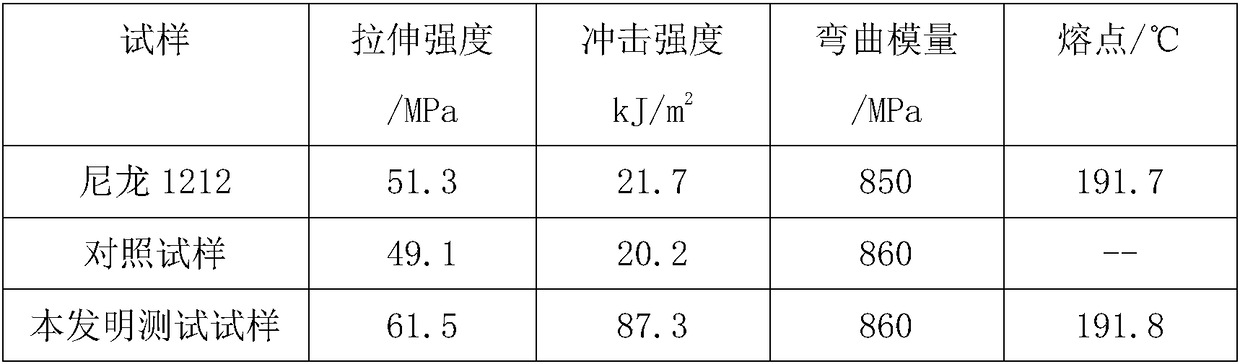

[0032] The formula of the multi-component graft copolymer blend is 30 parts of thermoplastic elastomer POE; 3 parts of bismaleamide diamine acid mixture; 70 parts of homopolypropylene, the preparation method is the same as that of Example 1; the multi-component graft 20 parts of the copolymerized blend and 121280 parts of nylon were melt-blended, and the preparation method and test method were the same as in Example 1.

[0033] Table 2. Embodiment 2 nylon composite material and pure nylon 1212 mechanical properties and melting point

[0034]

Embodiment 3

[0036] The multi-component formula is 10 parts of thermoplastic elastomer POE; 1 part of bismaleic diamic acid mixture; 90 parts of homopolypropylene, the preparation method is the same as that of Example 1; 30 parts of the multi-component graft copolymerization blend Melt blending with nylon 121270 parts, the preparation method and test method are the same as in Example 1.

[0037] Table 3. Embodiment 3 nylon composite material and pure nylon 1212 mechanical properties and melting point

[0038] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com