Preparation and regulation method of high-chromaticness fluorescent carbon nanodots

A technology of carbon nano-dots and fluorescence, which is applied in nanotechnology, nano-optics, nano-technology, etc., can solve rare problems and achieve the effect of simple process, safe method and high-efficiency method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 0.25g o-phenylenediamine and 0.5g phenol, put them in a 20mL reaction kettle, add 15mL ethanol to it, put it in an oven, heat up to 200℃, keep it warm for 8 hours, and cool naturally to obtain fluorescent carbon nanodots The solution.

[0029] 2. Take out the solution obtained in step 1 and place it in acetone 100 times the volume of the solution after the reaction. After sonicating for 1 hour, place it in a high-speed centrifuge for centrifugation at 5000 rpm for 20 minutes.

[0030] 3. Remove the lower layer of precipitation and re-disperse it in ethanol of 3 times the volume of the solution after the reaction, ultrasonically for 60 minutes, remove the lower layer of solid, and dry.

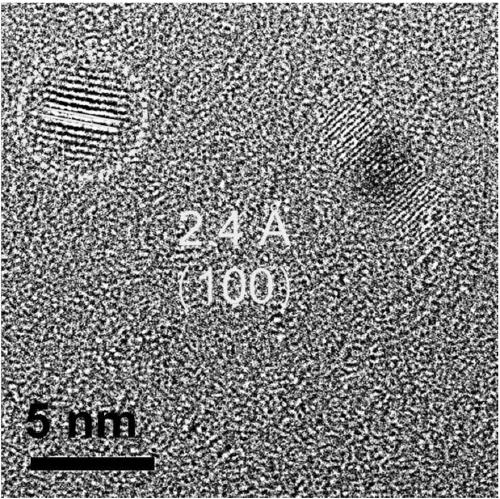

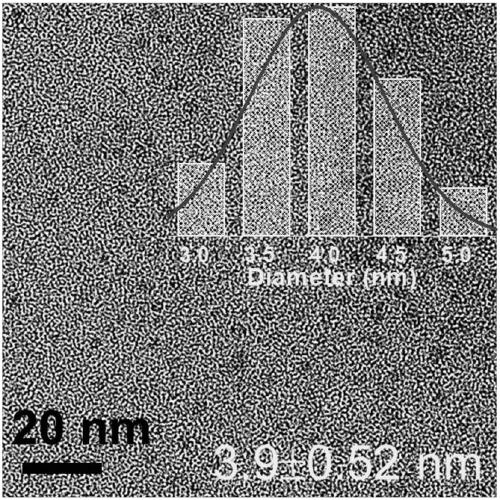

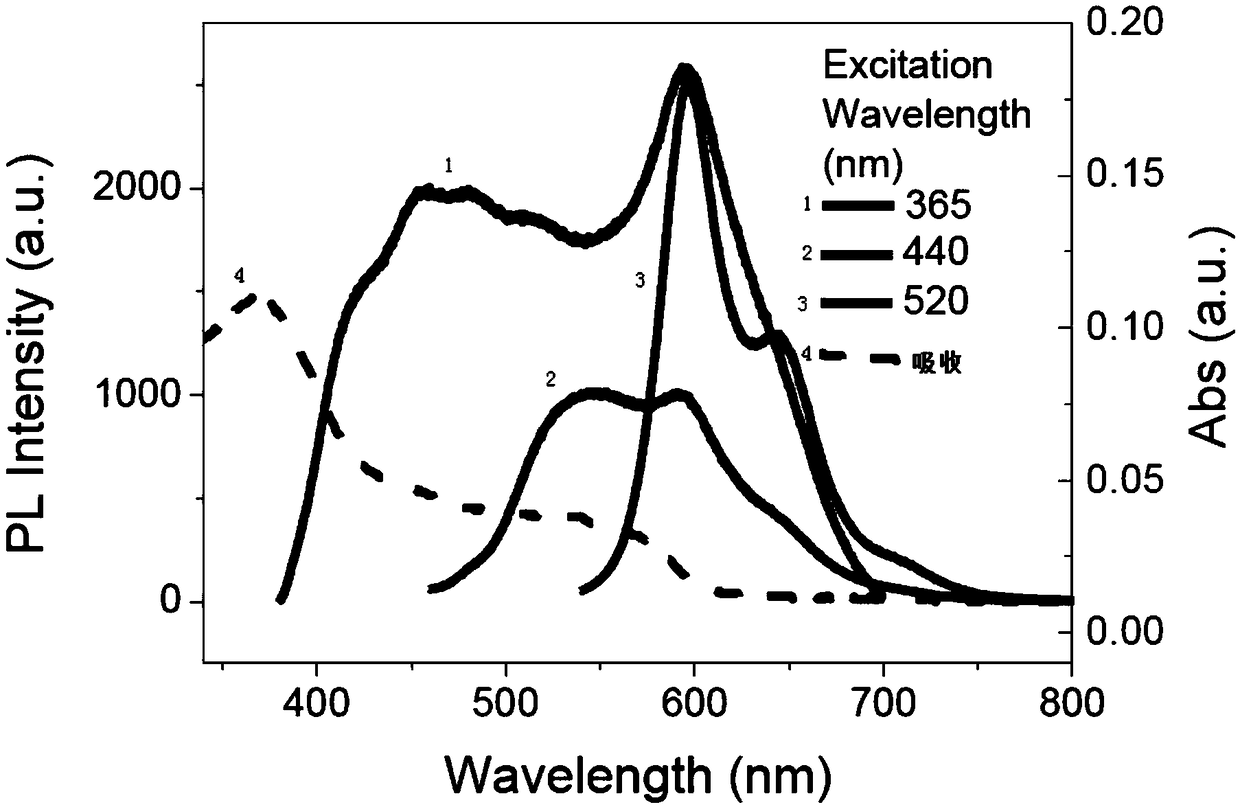

[0031] 4. Dissolve the solid obtained in step 3 in ethanol to obtain fluorescent carbon nanodots with high color quality. The CIE chromaticity coordinates are (0.33, 0.33), the CRI value is as high as 93, the CCT is 5453K, and the standard white light Emission can be applied to the pr...

Embodiment 2

[0033] 1. Weigh 0.1g p-phenylenediamine and 0.25g catechol, put them in a 20mL reactor, add 10mL N,N-dimethylformamide to it, put it in an oven, heat up to 180℃, keep warm After 12 hours, let it cool naturally to obtain a solution of fluorescent carbon nanodots.

[0034] 2. Take out the solution obtained in step 1 and place it in petroleum ether that is 1000 times the volume of the solution after the reaction. After sonicating for 0.5 hours, place it in a high-speed centrifuge for centrifugation at 1000 rpm for 30 minutes.

[0035] 3. Remove the lower layer of precipitation and re-disperse it in 5 times the volume of the solution after the reaction in ethanol, sonicate for 60 minutes, remove the lower layer of solid, and dry.

[0036] 4. Dissolve the solid obtained in step 3 in ethanol to obtain fluorescent carbon nanodots with high color quality. The CIE chromaticity coordinates are (0.33, 0.33), the CRI value is as high as 93, the CCT is 5453K, and the standard white light Emissio...

Embodiment 3

[0039] 1. Weigh 0.6g naphthalene diamine and 0.8g phloroglucinol, put them in a 20mL reaction kettle, add 15mL n-pentanol to it, put it in an oven, heat up to 160°C, keep it warm for 6 hours, and cool naturally to obtain A solution of fluorescent carbon nanodots.

[0040] 2. Take out the solution obtained in step 1 and place it in ethyl acetate 500 times the volume of the solution after the reaction. After sonicating for 1 hour, place it in a high-speed centrifuge and centrifuge at 5000 rpm for 20 minutes.

[0041] 3. Remove the lower layer of precipitation and re-disperse it in ethanol of 8 times the volume of the solution after the reaction, sonicate for 60 minutes, remove the lower layer of solid, and dry.

[0042] 4. Dissolve the solid obtained in step 3 in ethanol to obtain fluorescent carbon nanodots with high color quality. The CIE chromaticity coordinates are (0.33, 0.33), the CRI value is as high as 93, the CCT is 5453K, and the standard white light Emission can be applied ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com