Method for preparing sodium diethylene glycol isophthalate-5-sulfonate modified polyester

A technology of diethylene glycol isophthalate and diethylene glycol phthalate is applied in the field of preparing diethylene glycol isophthalate-5-sodium sulfonate modified polyester, which can solve difficult Accurately determine the dosage ratio, increase the complexity of the process, etc., to achieve high coloring rate, good color fastness, and improve the effect of transesterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

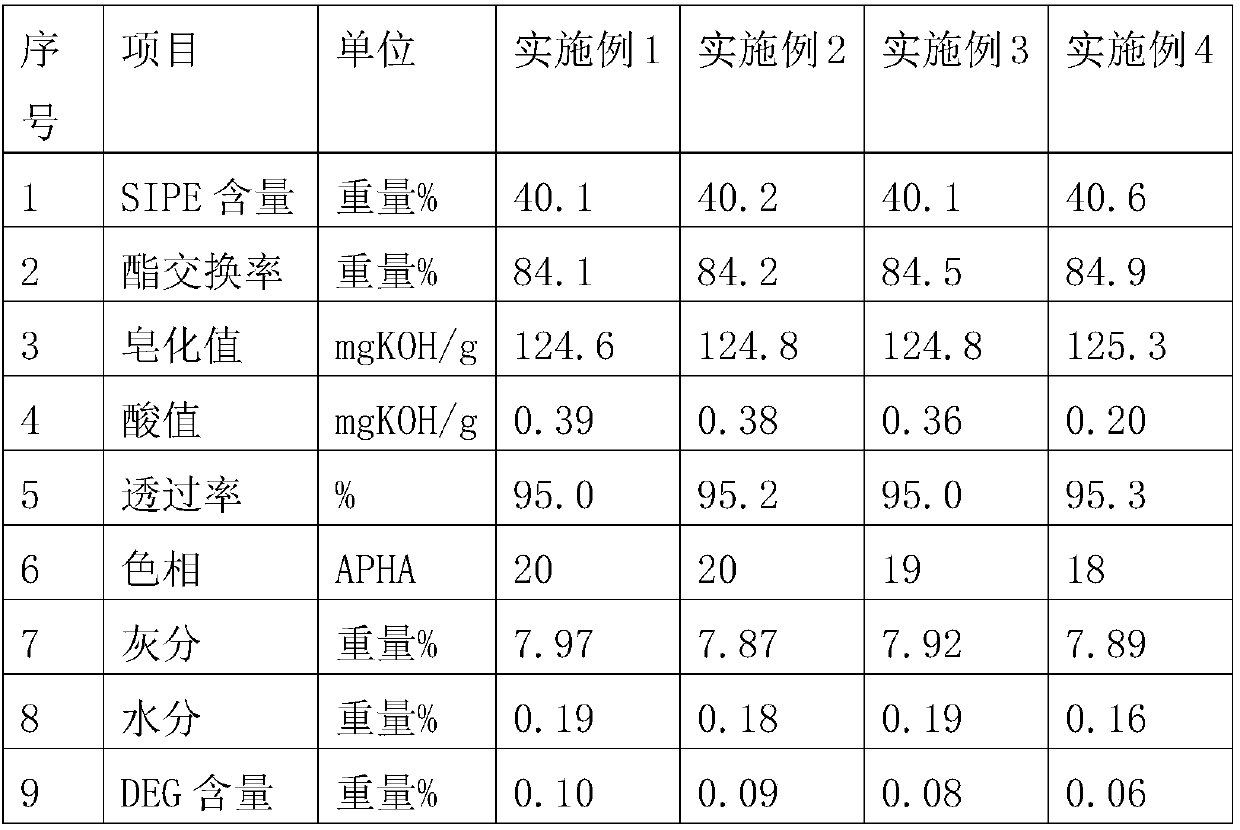

[0029] Put 500kg of dimethyl isophthalate and 1250kg of ethylene glycol into the reaction kettle, start the agitator, add 0.25kg of sodium acetate and 0.75kg of calcium acetate, close the feeding port, pass in nitrogen protection, and start the heater , the material was heated from room temperature to 185° C. within 2 hours. After reacting for about 4-6 hours, stop the reaction to obtain a reaction product containing diethylene glycol isophthalate. The reaction product was cooled to below 130°C, and its physical and chemical properties were characterized. See Table 1 below for the results.

Embodiment 2

[0031] Put 500kg of dimethyl isophthalate and 1250kg of ethylene glycol into the reaction kettle, start the agitator, add 0.5kg of sodium acetate and 1.5kg of calcium acetate, close the feeding port, pass in nitrogen protection, and start the heater , the material was heated from room temperature to 185° C. within 2 hours. After reacting for about 4-6 hours, stop the reaction to obtain a reaction product containing diethylene glycol isophthalate. The reaction product was cooled to below 130°C, and its physical and chemical properties were characterized. See Table 1 below for the results.

Embodiment 3

[0033] Put 500kg of dimethyl isophthalate and 1250kg of ethylene glycol into the reactor, start the agitator, add 0.25kg of sodium acetate, 0.75kg of calcium acetate and 0.6kg of nickel acetate, close the feeding port, and feed Under nitrogen protection, start the heater, and heat the material from room temperature to 185° C. within 2 hours. After reacting for about 4-6 hours, stop the reaction to obtain a reaction product containing diethylene glycol isophthalate. The reaction product was cooled to below 130°C, and its physical and chemical properties were characterized. See Table 1 below for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com