Continuous process and device for synthesizing sodium bis(2-hydroxyethyl) 5-sulphonatoisophthalate with high ester exchange rate through catalytic reaction rectification

A bishydroxyethyl isophthalate and catalytic reaction technology, which is applied in the field of modified polyester production, can solve the problem of large changes in heat demand of transesterification reactors, periodic fluctuations in the operation of heat medium systems, and darkening of product appearance, etc. problems, to achieve the effect of low transesterification rate requirements, stable product quality, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

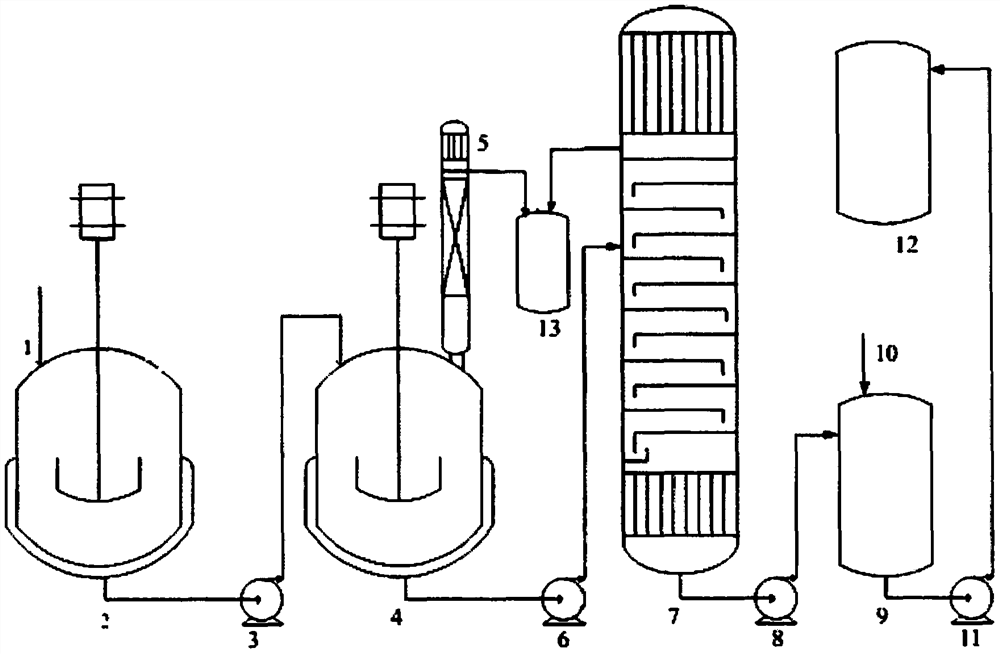

[0033] Such as figure 1 Shown, catalytic reaction rectification of the present invention synthesizes the continuous process of high transesterification rate bishydroxyethyl isophthalate-5-sodium sulfonate, and concrete production process is as follows:

[0034] (1) According to the ratio of raw materials, ethylene glycol (EG), dimethyl isophthalate-5-sodium sulfonate (SIPM) is used in a molar ratio of 10:1, and the catalyst (Zn(AC) 2 ) and EG mass ratio (Zn(AC) 2 / EG)=1:500 is continuously put into the beating tank 2 from the material inlet 1, and after mixing evenly, the slurry flows through the material pipeline from the discharge valve at the bottom of the beating tank 2 and is continuously sent into the pre-esterification reaction kettle by the slurry delivery pump 3 4. The pre-transesterification tank 4 maintains a temperature of 170°C and a pressure of 0.1MPa (gauge pressure) to perform a pre-transesterification reaction until the conversion rate of bishydroxyethyl isoph...

Embodiment 2

[0039] Such as figure 1 Shown, a kind of catalytic reaction rectification of the present invention synthesizes the semi-continuous process and the device of high transesterification rate bishydroxyethyl isophthalate-5-sodium sulfonate, and concrete production process is as follows:

[0040] Raw material ratio: ethylene glycol (EG), dimethyl isophthalate-5-sodium sulfonate (SIPM) molar ratio (SIPM / EG) = 1:20, catalyst zinc acetate (Ca(AC) 2 ), ethylene glycol (EG) mass ratio (Ca(AC) 2 / EG)=1:2000; through the feed port 1, it is continuously put into the beating tank 2, and after stirring evenly, the slurry flows through the material pipeline from the discharge valve at the bottom of the beating tank 2, and is continuously sent into the pre-esterification reaction by the slurry delivery pump 3 Kettle 4, and maintain beating tank 2 liquid level; Pre-esterification reactor 4 maintains temperature 230 ℃, keeps reaction pressure 0.5MPa (gauge pressure), residence time 1h, SIPE conv...

Embodiment 3

[0042] 1. Put 1000.0kg ethylene glycol (EG) into the beating tank 2, 5.0kg manganese acetate (Mn(AC) 2 ), 448.2kg dimethyl isophthalate-5-sodium sulfonate (SIPM), after being stirred evenly, is sent into the pre-esterification reaction kettle 4 continuously by the slurry delivery pump 3 with 145kg / h, and in good time to the beating tank 2 Feed again to maintain the liquid level of the beating tank 2 within a certain range.

[0043] 2. The temperature of the pre-transesterification reactor 4 is stabilized at 190°C, the pressure is controlled at 0.2MPa (gauge pressure), the residence time of the material is 2h, and the product is continuously pumped into the final transesterification reaction by the pre-transesterification material delivery pump 6 at 139.2kg / h Rectifying tower 7; After the methanol produced by transesterification in the pre-transesterification reactor 4 is separated by the methanol fractionation tower 5, the crude methanol is extracted at the top of the tower at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com