Method for molding high-frequency and high-speed acrylic resin copper-cladded plate

A nitrile-based resin and molding process technology, which is applied in the field of high-frequency and high-speed nitrile resin copper-clad laminate molding technology, can solve the problems of increased residual copper-clad laminates, cumbersome dispersion steps, low efficiency, etc., and achieve outstanding dielectric properties , the synthetic method is simple, the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

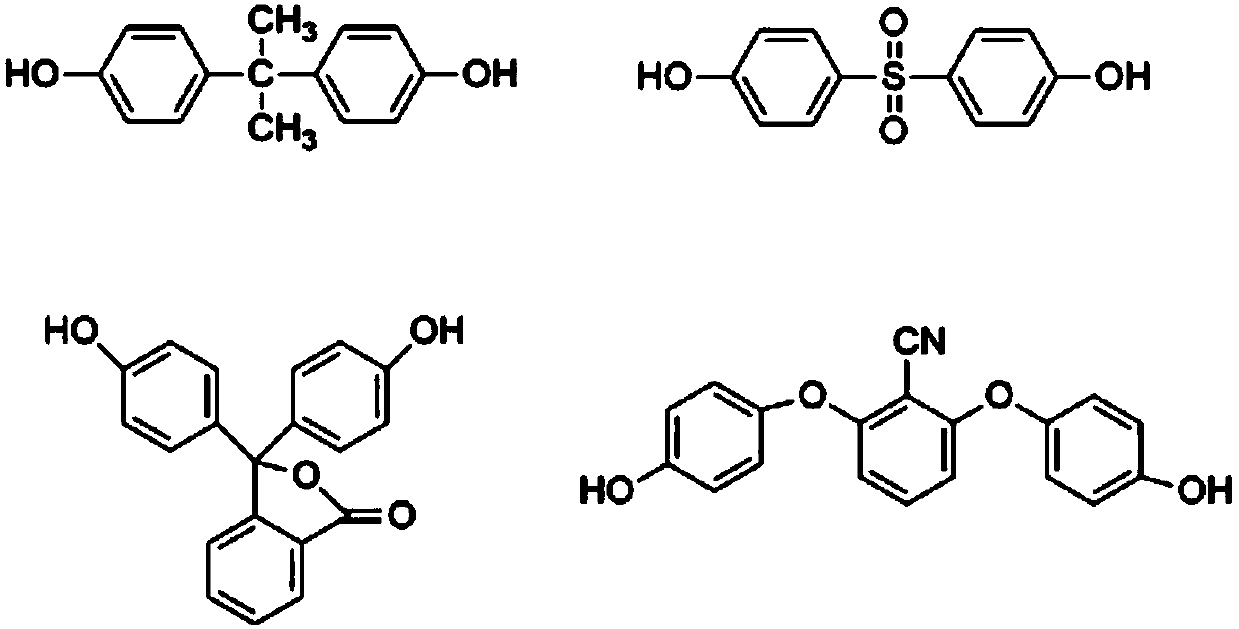

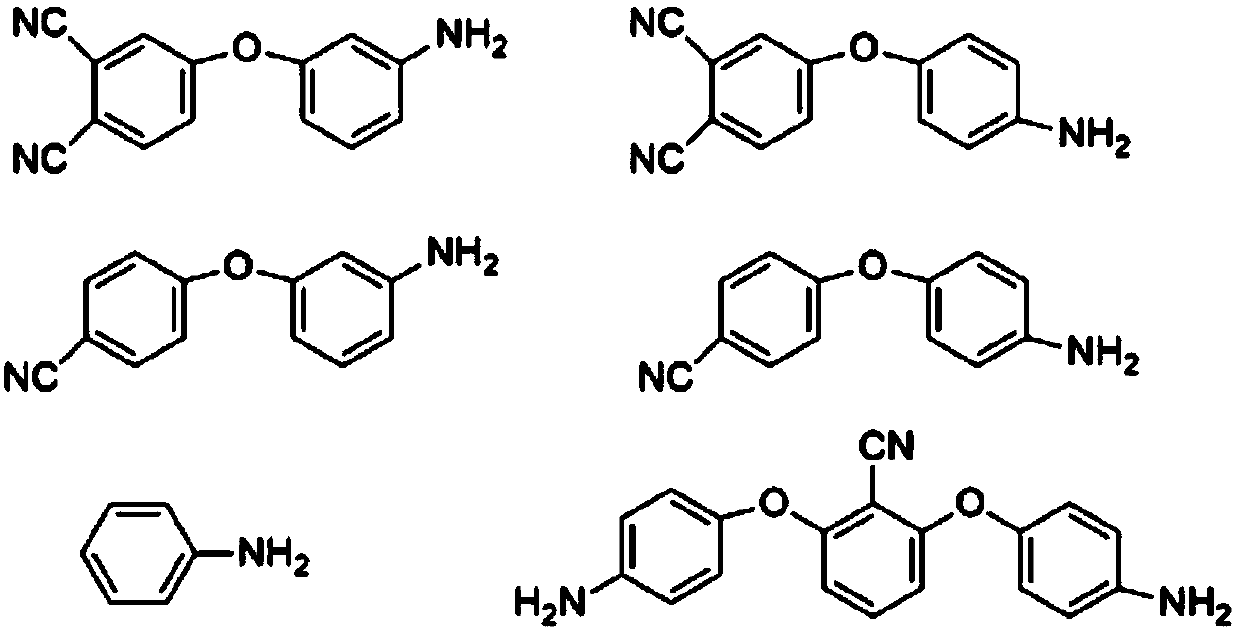

[0041](1) Synthesis of Nitrile Resin

[0042] (1) First, dry bisphenol S, 4-(3-aminophenoxy)phthalonitrile, and paraformaldehyde in a drying oven at 80°C for 2 hours;

[0043] (2) 28 grams of bisphenol S, 42 grams of 4-(3-aminophenoxy) phthalonitrile, 3.5 grams of aniline, and 12 grams of paraformaldehyde were added to a tank containing 23.2 grams of DMF and 11.6 grams of toluene In the three-necked flask, stir at room temperature at 120 rpm for 10 minutes, then raise the temperature to 100 °C at a heating rate of 5 °C / min, keep the stirring speed at 120 rpm, and keep the temperature constant until the end of the reaction. The constant temperature reaction time is 6 hours;

[0044] (3) After the reaction, raise the temperature to 130°C, keep stirring at a constant temperature to continue the reaction for 2.5 hours, and distill 10 grams of toluene solvent;

[0045] (4) After the reaction, a viscous brown liquid is obtained, which is a nitrile-based resin that can be used in th...

Embodiment 2

[0054] (1) Synthesis of Nitrile Resin

[0055] (1) First, dry bisphenol A, 4-(3-aminophenoxy)phthalonitrile, and paraformaldehyde in a drying oven at 80° C. for 2 hours;

[0056] (2) 22.8 grams of bisphenol A, 42 grams of 4-(3-aminophenoxy) phthalonitrile, 3.5 grams of aniline, and 12 grams of paraformaldehyde were added to a tank containing 23.2 grams of DMF and 11.6 grams of toluene In the three-necked flask, stir at room temperature at 120 rpm for 10 minutes, then raise the temperature to 110 °C at a heating rate of 5 °C / min, keep the stirring speed at 120 rpm, and keep the temperature constant until the end of the reaction. The constant temperature reaction time is 5 hours;

[0057] (3) After the reaction is completed, the temperature is raised to 135° C., and the reaction is continued for 2.5 hours while stirring at a constant temperature, and 10 grams of toluene solvent is evaporated;

[0058] (4) After the reaction, a viscous brown liquid is obtained, which is a nitril...

Embodiment 3

[0067] (1) Synthesis of Nitrile Resin

[0068] (1) First, phenolphthalein, 4-(4-aminophenoxy)phthalonitrile, and paraformaldehyde were dried in a drying oven at 80° C. for 2 hours;

[0069] (2) Add 31.8 grams of phenolphthalein, 40 grams of 4-(4-aminophenoxy)phthalonitrile, 4.65 grams of benzene, and 12 grams of paraformaldehyde to a three-necked flask containing 30.3 grams of DMF and 15.1 grams of toluene in sequence , after stirring at 120 rpm at room temperature for 10 minutes, the temperature was raised to 110 °C at a heating rate of 5 °C / min, and the stirring speed was maintained at 120 rpm, and the temperature was kept constant until the reaction was completed, and the constant temperature reaction time was 4 hours;

[0070] (3) After the reaction, the temperature was raised to 130° C., and the reaction was continued for 3 hours while stirring at a constant temperature, and 14 grams of toluene solvent was evaporated;

[0071] (4) A viscous tan liquid is obtained after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com