Aqueous graphene heavy-anticorrosive coating and preparation method thereof

A water-based graphene, heavy-duty anti-corrosion technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as difficulty in application, achieve low volatile organic content, high corrosion resistance, and solve layered sedimentation bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

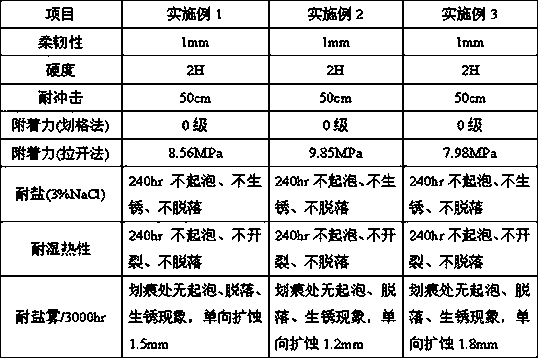

Embodiment 1

[0025] (1) Water-based graphene slurry

[0026] a. Add 80 parts of water-based resin, 1 part of functional dispersant, 10 parts of modified graphene with a sheet thickness of 50nm, and 10 parts of coagent into the dispersing machine in order to disperse at high speed for 20 minutes to obtain a dispersion;

[0027] b. Grind the above-mentioned dispersion to a fineness of less than 30 μm by shaking, sand milling, etc., and control the temperature below 50°C to obtain a water-based graphene prefabricated slurry;

[0028] (2) A component

[0029] a. Add 15 parts of the water-based graphene slurry obtained in step (1) to 20 parts of water-based epoxy resin, and disperse at a high speed for 10 minutes at 2000 rpm to obtain a resin dispersion;

[0030] b. Add 0.2 parts of TEGO822, 0.2 parts of 299, 0.4 parts of BYK-349, 0.2 parts of anti-flash rust agent and 15 parts of deionized water into the resin dispersion prepared in step b, stir well and slowly add 50 parts of improved zinc p...

Embodiment 2

[0035] (1) Water-based graphene slurry

[0036] a. Add 60 parts of water-based resin, 0.2 parts of functional dispersant, 10 parts of modified graphene with a sheet thickness of 50nm, and 5 parts of coagent into the disperser in order to disperse at high speed for 10 minutes to obtain a dispersion;

[0037] b. Grind the above-mentioned dispersion to a fineness of less than 30 μm by shaking, sand milling, etc., and control the temperature below 50°C to obtain a water-based graphene prefabricated slurry;

[0038] (2) A component

[0039] a. Add 5 parts of the water-based graphene slurry obtained in step (1) to 10 parts of water-based epoxy resin, and disperse at a high speed for 20 minutes at 1000 rpm to obtain a resin dispersion;

[0040] b. Add 0.3 parts of TEGO822, 0.2 parts of 299, 0.2 parts of BYK-349, 0.3 parts of anti-flash rust agent and 10 parts of deionized water into the resin dispersion prepared in step b, stir well and slowly add 55 parts of improved zinc powder ,...

Embodiment 3

[0045] (1) Water-based graphene slurry

[0046] a. Add 70 parts of water-based resin, 1 part of functional dispersant, 8 parts of modified graphene with a sheet thickness of 20nm, and 7 parts of coagent into the disperser in order to disperse at high speed for 15 minutes to obtain a dispersion;

[0047] b. Grind the above-mentioned dispersion to a fineness of less than 30 μm by shaking, sand milling, etc., and control the temperature below 50°C to obtain a water-based graphene prefabricated slurry;

[0048] (2) A component

[0049] a. Add 10 parts of the water-based graphene slurry obtained in step (1) into 15 parts of water-based epoxy resin, and disperse at a high speed for 15 minutes at 1500 rpm to obtain a resin dispersion;

[0050] b. Add 0.2 parts of TEGO822, 0.3 parts of 299, 0.3 parts of BYK-349, 0.2 parts of anti-flash rust agent and 13 parts of deionized water into the resin dispersion prepared in step b, stir well and slowly add 57 parts of improved zinc powder , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com