A tough soybean meal protein adhesive and preparation method thereof

A protein glue and soybean meal technology, which is used in the preparation of protein adhesives, animal glue or gelatin, and adhesives, etc. Formaldehyde release and other problems in the board, to achieve the effect of no harmful substance release, improved adhesive performance and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

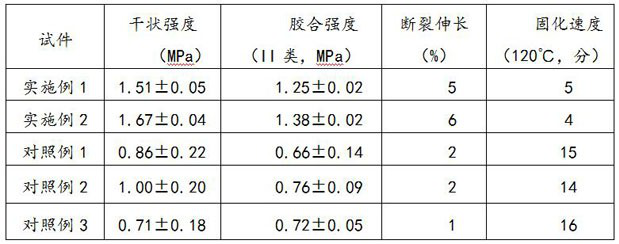

Examples

Embodiment 1

[0046] A toughness soybean protein adhesive consists of a weight of the following weight:

[0047] Softening water 70 kg;

[0048] Sliced bean protein powder 35 kg;

[0049] Tart 0.1 kg;

[0050] Sodium highly iodate 2kg;

[0051] Trivadic tetraamine 0.2kg;

[0052] Dodecylprocette hydrolycerol ether 0.3kg;

[0053] Curing agent 0.6kg.

[0054] When the toughness soybean glue adhesive in this example is used: The prepared umea protein adhesive prepolymer is stirred at normal temperature for 10 minutes at normal temperature, and it can be used.

Embodiment 2

[0056] A toughness soybean protein adhesive consists of a weight of the following weight:

[0057] Softening water 70 kg;

[0058] Sliced bean protein powder 35 kg;

[0059] Tart 0.3kg;

[0060] 5kg of sodium methoate;

[0061] Trivadic tetraamine 0.5kg;

[0062] Dodecyllate water glycene ether 0.8kg;

[0063] Curing 1kg.

Embodiment 3

[0065] Method for preparing a toughness soybean protein adhesive, including the following steps:

[0066] (1) Weighing the components of the components in the weight ratio in the above-described toughness soybean meal protein adhesive;

[0067] (2) Puboy meal, water, trypsin, uniformly disperse in the dispersion dielectric water, and the water bath is warmed to 40 ° C for 30 minutes, and the temperature rises to 80 ° C for 10 minutes;

[0068] (3) Gas sodium methate is added to the mixture obtained by the step 2, and the temperature is raised to 50 ° C, the pH is 4.0, and the reaction is 5 hours, and the triamic tetramine is added at 50 ° C for 2 hours, and then the temperature is 90 ° C, and the reaction is 6 hours. ;

[0069] (4) The mixture of step 3 is warmed by 80 ° C, adjusting pH = 10, and adding dodecytic hydrated glycidyl ether to the reaction for 3 hours, and the temperature is obtained, that is, the toughness soybean meal protein adhesive prepolymer;

[0070] (5) The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com