Cellulase-producing bacillus licheniformis, microbial fermentation preparation thereof and application of cellulase-producing bacillus licheniformis

A technology of Bacillus licheniformis and microbial fermentation, applied in the direction of microorganisms, microorganisms, and methods based on microorganisms, to achieve the effects of facilitating digestion and absorption, short fermentation time, and high number of viable bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

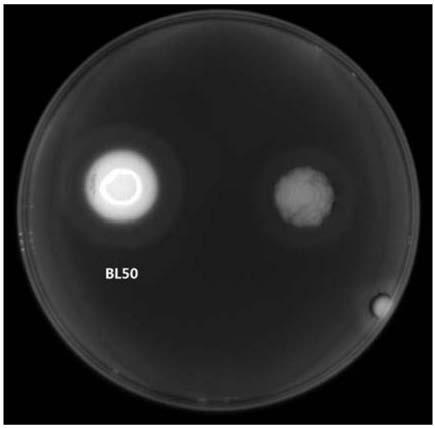

[0058] Example 1: Isolation and screening of Bacillus licheniformis

[0059] Take 10g of Shanxi Fenjiu Daqu sample in 90mL of sterile saline, place on a shaker, shake at 30°C and 200rpm for 30min, and then dilute 10 times to 10 -8 . Take 1mL10 -8 Add 20mL 80°C solid medium of Bacillus licheniformis in a melted state to a 6cm plate, mix well and cool to room temperature, and after solidification, place it upside down in a 30°C constant temperature incubator for 24 hours. After 24 hours, it can be observed on the plate that multiple colonies are formed. The colonies are round colonies with irregular edges and wrinkles on the surface, and are positive by Gram staining; The morphology is long rod-like, single, paired or chain-like; this feature is the same as that of Bacillus licheniformis.

[0060] Pick a single colony (concentration is 10 9 CFU / mL) were inoculated on a CMC screening medium plate, and cultured upside down at 30°C for 24 hours. After 24 hours, 5 mL of 1w / v% C...

Embodiment 2

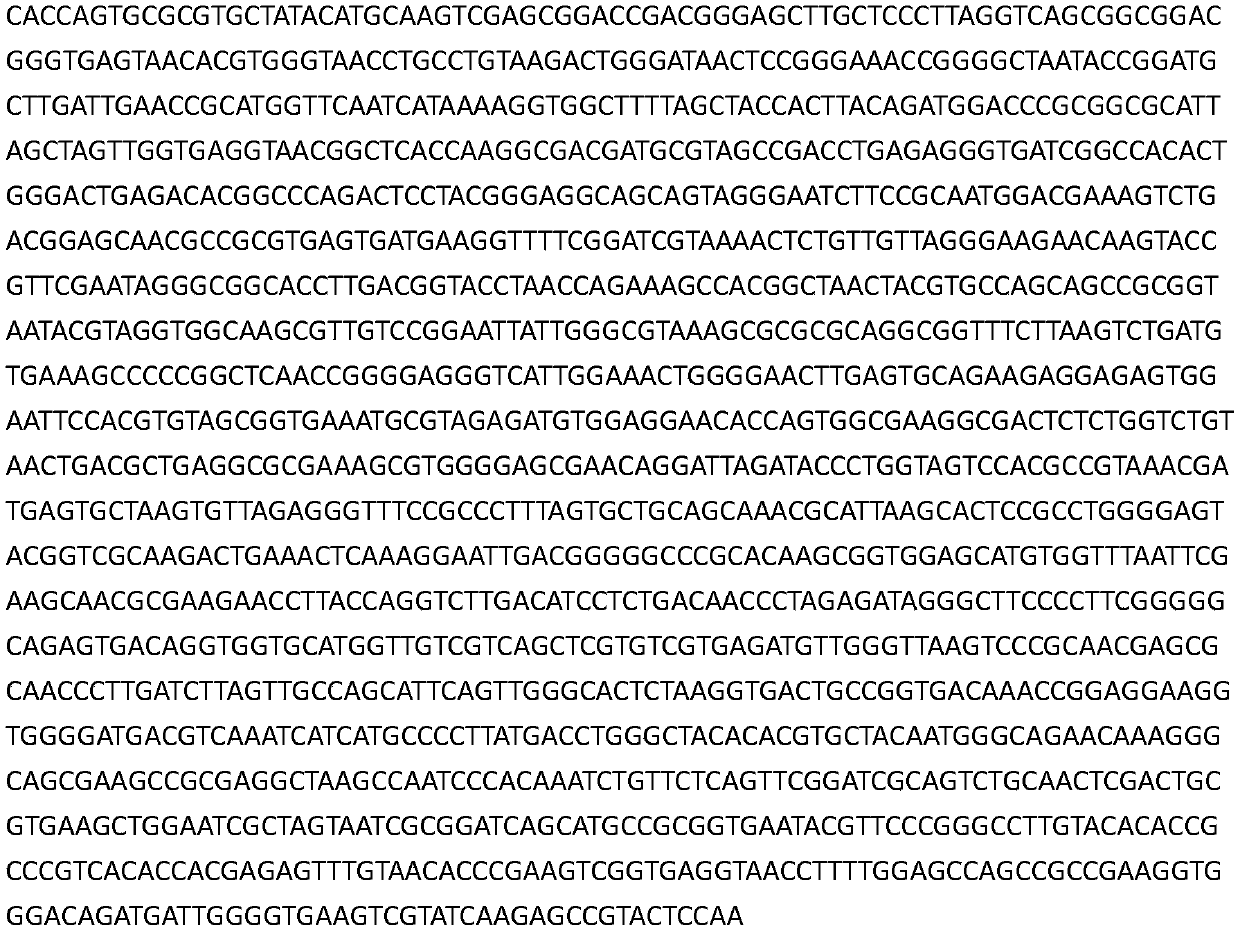

[0062] Example 2: Identification of Bacillus licheniformis 50

[0063] 2.1 Identification of colony morphology

[0064] The strain isolated in Example 1 was observed by biological characteristics, and further morphological identification (comprising: observation of the shape and edge of the colony, Gram staining, etc.) was carried out. The above-mentioned identification standards refer to "Berger's Bacteria Identification Handbook", published in Science Society, 1984 and "Common Bacterial System Identification Manual", Science Press, 2001. After the isolated bacterial strain was cultivated at 30°C for 24 hours on the solid medium of Bacillus licheniformis, the colony form was a round colony with irregular edges and wrinkles on the surface, which was positive by Gram staining; Observed below, the thalline shape grows rod-shaped, single, paired or chain-like arrangement; this feature is the same as the morphological feature of Bacillus licheniformis.

[0065] 2.2 Taxonomic...

Embodiment 3

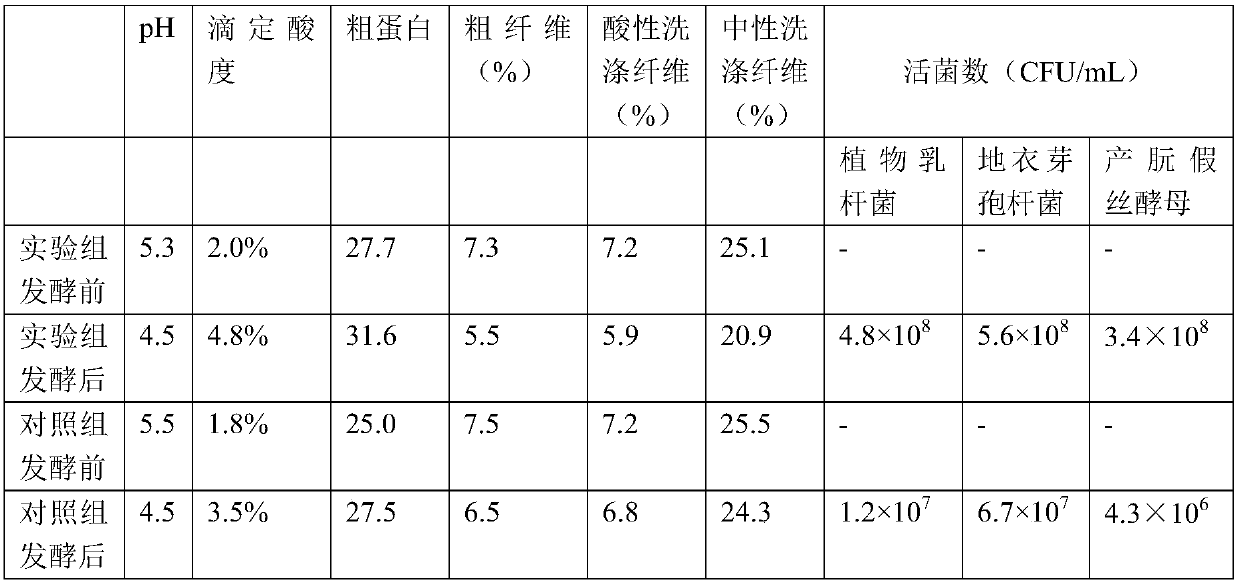

[0069] The preparation of embodiment 3 microbial fermentation agent

[0070] Bacillus licheniformis 50, Lactobacillus plantarum (isolated from commercially available fermented milk) and Candida utilis (isolated from commercially available fermented feed) cultured bacterial liquid were obtained respectively by the following steps:

[0071] (1) Bacillus licheniformis: The Bacillus licheniformis 50 obtained in Example 1 was inoculated into the Bacillus licheniformis culture medium at an inoculation amount of 1 v / v%, placed on a constant temperature shaker, and cultivated overnight at 30° C. and 200 rpm.

[0072](2) Lactobacillus plantarum: Lactobacillus plantarum was inoculated into MRS medium at an inoculation amount of 1v / v%, placed on a constant temperature shaker, and cultured overnight at 30°C and 200rpm.

[0073] (3) Candida utilis: Candida utilis was inoculated into YPD medium at an inoculum size of 1v / v%, placed on a constant temperature shaker, and cultured overnight at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com