A rare earth-iron-silicon-based magnetic refrigeration composite material and its preparation method

A composite material and magnetic refrigeration technology, which is applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve problems such as difficulty in forming a continuous network structure, high density of copper metal, and poor mechanical properties , to achieve the effects of increased thermal resistance at the interface between particles, low cost, enhanced thermal conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In some more specific embodiments, the preparation method includes the following steps:

[0059] (1) According to its general chemical formula R x (Fe 1-a-b co a mn b ) 13-y Si y A z Prepare raw materials (convert alloy atomic percent to mass percent, then weigh raw materials). When A includes hydrogen, prepare raw materials other than hydrogen according to the general chemical formula;

[0060] (2) Place the prepared raw materials in a smelting furnace, and smelt them under the protection of high-purity inert gas to obtain alloy ingots; or place the raw materials in a vacuum induction quick-setting furnace, and melt the alloy liquid Pouring on a rotating copper roller to prepare quick-setting sheets;

[0061] (3) anneal the material prepared in step (2) in vacuum or inert gas, and then quench rapidly to obtain 13 The rare earth-iron-silicon-based alloy of the type crystal structure, the operation of the step (2) and the step (3) are all realized by those skill...

Embodiment 1

[0068] Example 1LaFe 11 co 0.8 Si 1.2 / Al (Al content 10wt.%) magnetic refrigeration composite material

[0069] (1) Press LaFe 11 co 0.8 Si 1.2 Chemical formula ingredients, put the prepared La, Fe, Co, Si raw materials into the crucible of the vacuum induction quick-setting furnace, and evacuate to 5×10 -2 Pa, after filling with high-purity argon (99.999% or more) to 0.05MPa. Turn on the intermediate frequency power supply, heat for a period of time, and start to smelt the metal. After the raw materials are completely melted and kept warm for 5 minutes, pour the alloy liquid onto the rotating copper roller with a speed of 1.7m / s to obtain LaFe 11 co 0.8 Si 1.2 quick-setting tablets;

[0070] (2) Break the quick-setting sheet obtained in step (1), then wrap it with a Mo sheet and put it into a quartz tube, and vacuumize it to 1×10 -4 Pa, filled with argon gas of 0.05MPa, and sealed the quartz tube;

[0071] (3) Put the sealed quartz tube in step (2) into a muffle f...

Embodiment 2

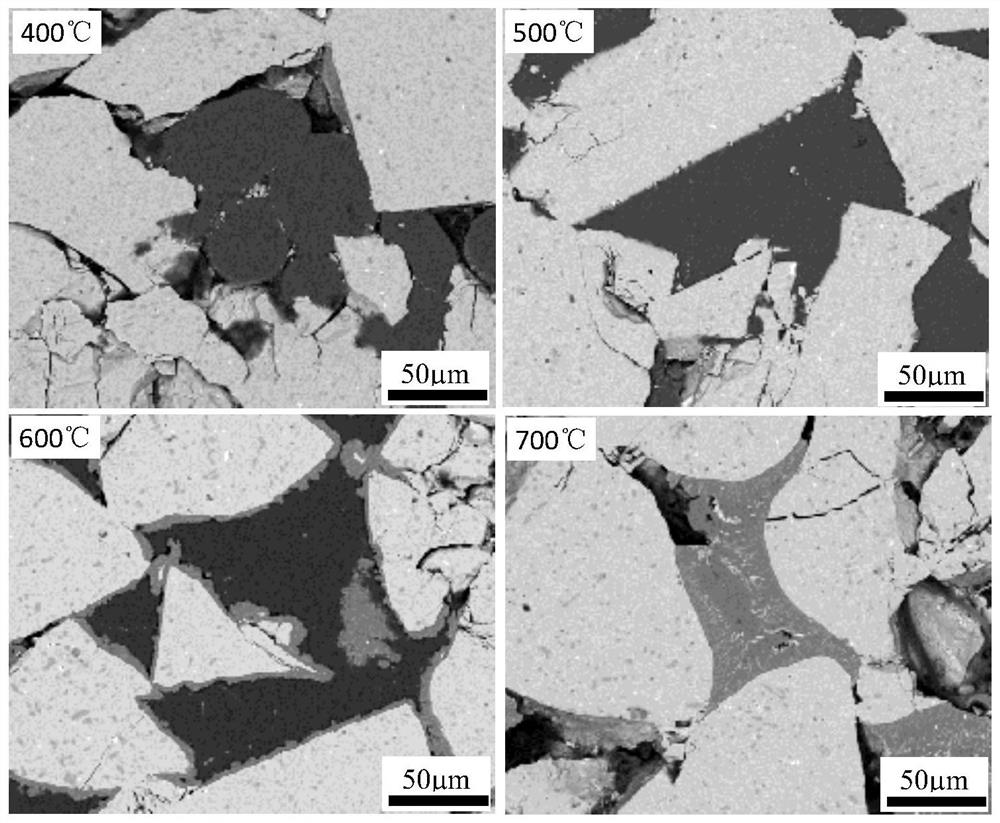

[0081] Three, test the LaFe that step (5) makes with electronic universal testing machine 11 co 0.8 Si 1.2 / Al composites room temperature compressive strength. Figure 5 Typical stress-strain curves of hot-pressed samples at 400°C, 500°C, 600°C and 700°C are given, from Figure 5 It can be seen that the stress-strain curve of each sample approximately satisfies the linear relationship at the initial stage of loading, and is in the elastic deformation zone, and then the stress rises very slowly with the strain, presenting a very narrow approximate platform zone, and then falls, and the sample is destroyed. The fracture strength of the samples increases first and then decreases with the increase of the hot-pressing temperature. Among them, the fracture strength of the samples hot-pressed at 600℃ is the highest, reaching 186MPa. The high strength of the hot-pressed sample may come from the reinforcement effect of the micro-thick reaction layer. Example 2LaFe 11 co 0.8 Si ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com