Preparation method of shiitake mushroom spawn

A shiitake mushroom stick and purpose technology, applied in botany equipment and methods, mushroom cultivation, horticulture, etc., can solve the problems of mushroom stick falling, mycelium shaking, multi-manual, etc., to avoid the trouble of garbage disposal and reduce energy consumption Consumption, the effect of expanding the supply of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of mushroom sticks, specifically comprising the following steps:

[0052] Step 1. Select 70Kg of discarded non-rotten non-rotten food, 20Kg of soybean meal, 10Kg of corn cob, and 1Kg of brown sugar, mix and pulverize them into 10-mesh powder to obtain a mixed powder.

[0053] Step 2, spreading the mixed powder obtained through ultraviolet sterilization for 15 minutes, then adding 1Kg of gypsum powder, 2Kg of lime powder and sterilized water to adjust the pH of the mixture to ~6, with a relative humidity of 75%, to obtain a mixed substrate.

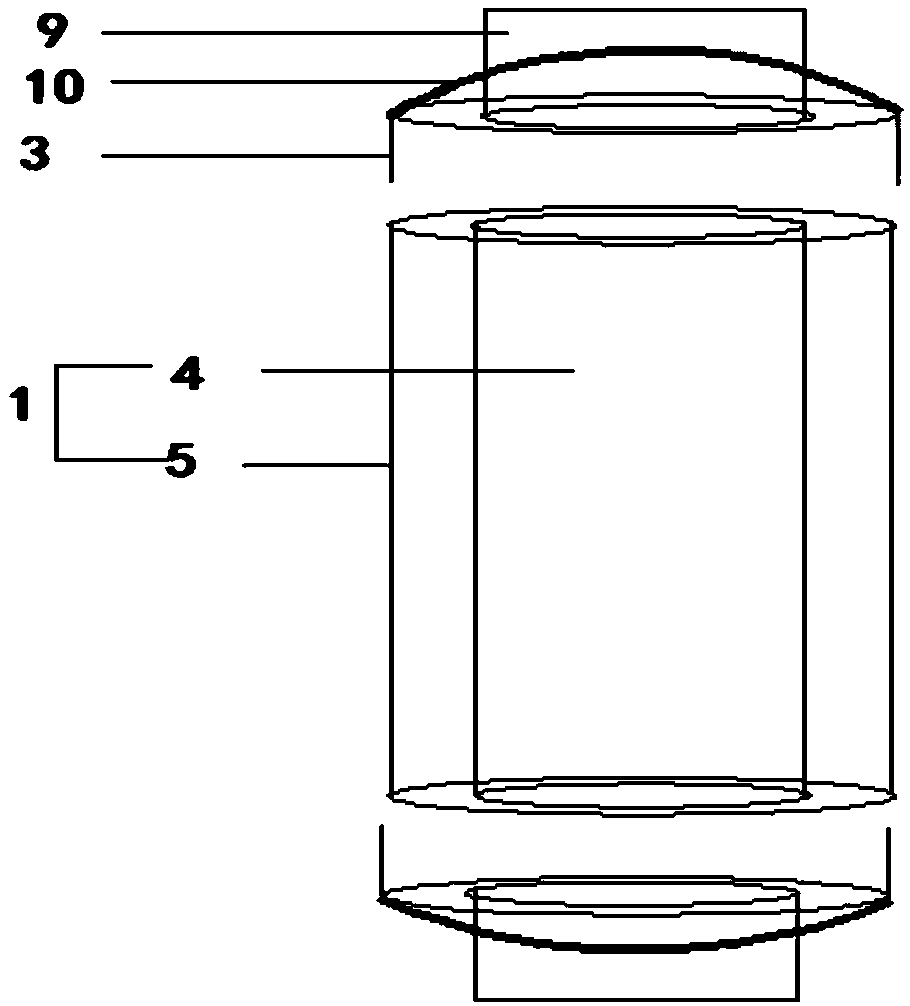

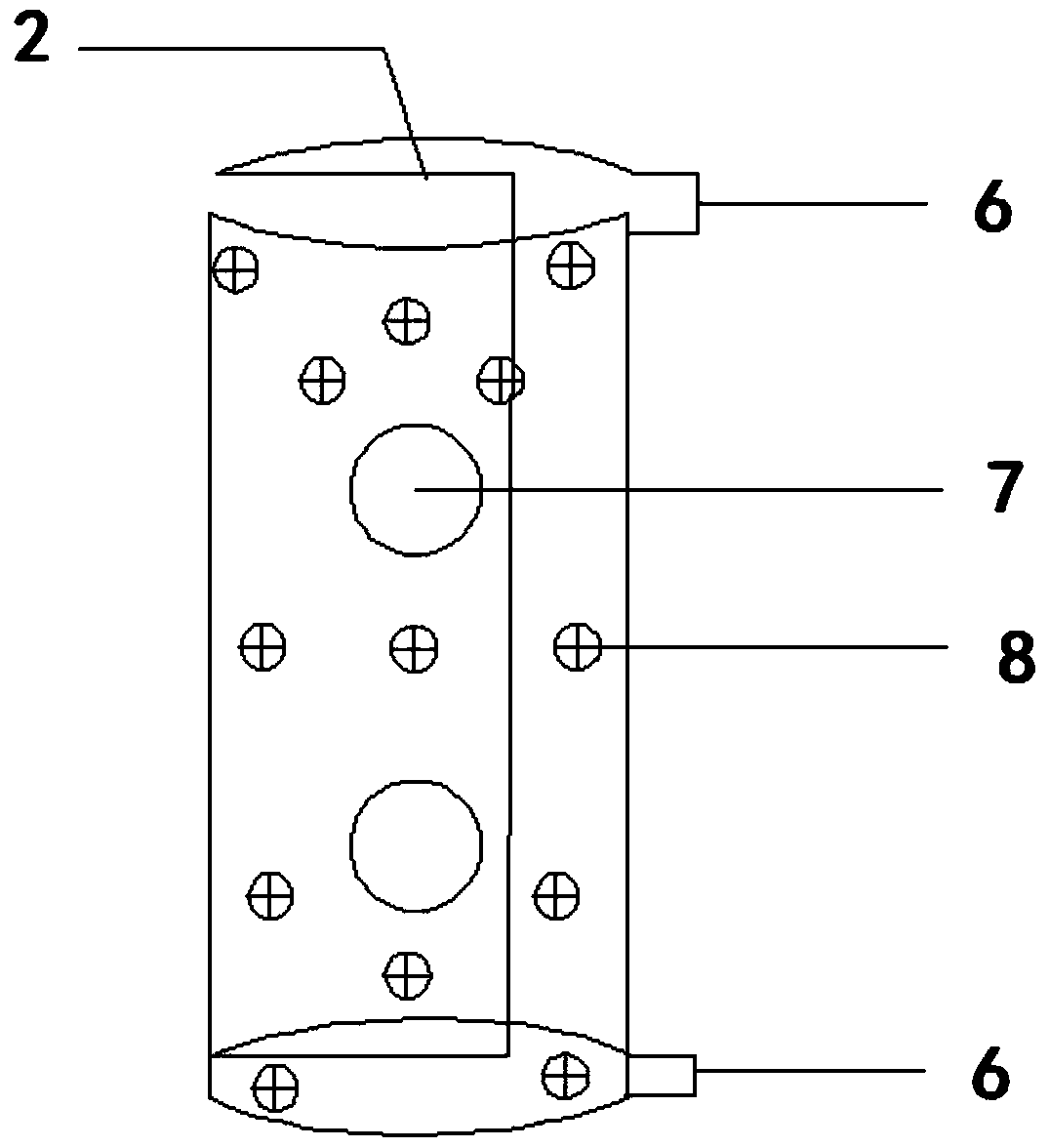

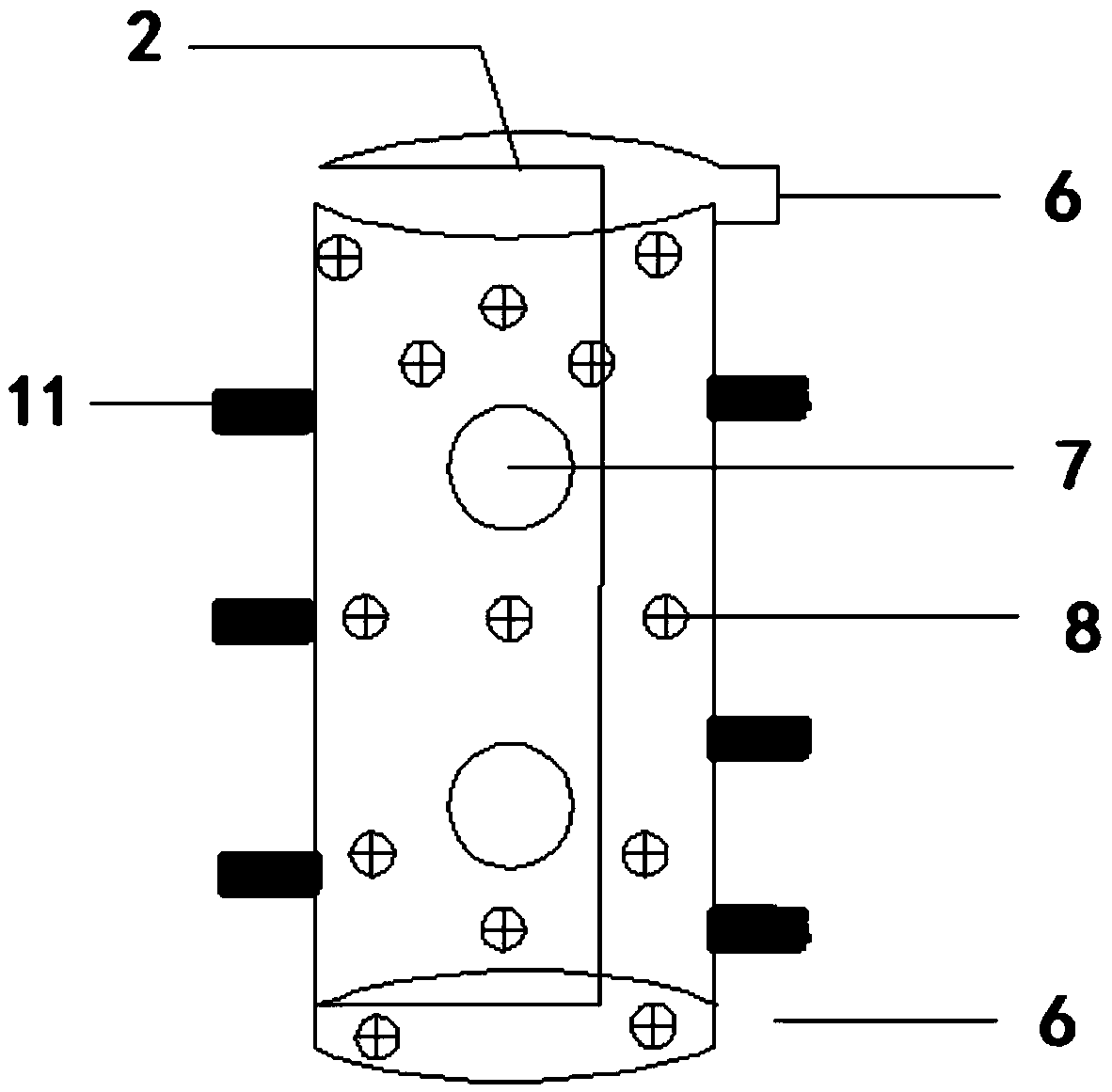

[0054] Step 3, transfer the mixed substrate into the inner cylinder, then insert 4 parts of mushroom strains in the inoculation hole of the inner cylinder, cover the outer cylinder and cover the lid, Promptly obtain described bacterium stick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com