Hyaluronic acid moisturizing original liquid and preparation method thereof

A technology of hyaluronic acid water and raw materials, which is applied in the field of hyaluronic acid moisturizing stock solution and its preparation, can solve the problems of inconspicuous skin care effect and high production cost, and achieve the effects of reducing the incidence of glycerin allergy, controlling production cost, and simple formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

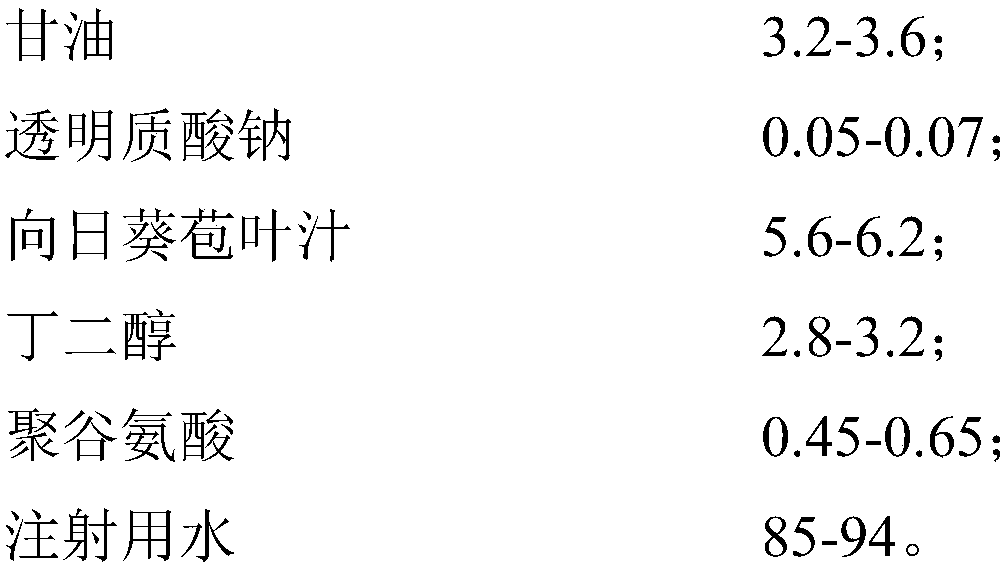

[0051] A hyaluronic acid moisturizing stock solution is made of the following raw materials in parts by weight:

[0052]

[0053] The preparation method is as follows:

[0054] (1) Wash and drain the fresh sunflower bracts and cut them into thin strips with a width of 2-3cm, and completely immerse the thin sunflower bracts in 1.5% ferrous chloride solution, at a constant temperature of 45°C Soak under water for 30 minutes, remove and rinse repeatedly with distilled water for 5 minutes and drain, put the sunflower bracts into a juice extractor and squeeze to obtain sunflower bract juice;

[0055] (2) Accurately weigh glycerin, sodium hyaluronate, butylene glycol, and polyglutamic acid, sequentially add to 5 times the amount of water for injection, and stir until completely dissolved to obtain a raw material mixture;

[0056] (3) Heat the above-mentioned raw material mixture to 65°C, slowly add the sunflower bract juice into it, stir rapidly while adding, add water to the fu...

Embodiment 2

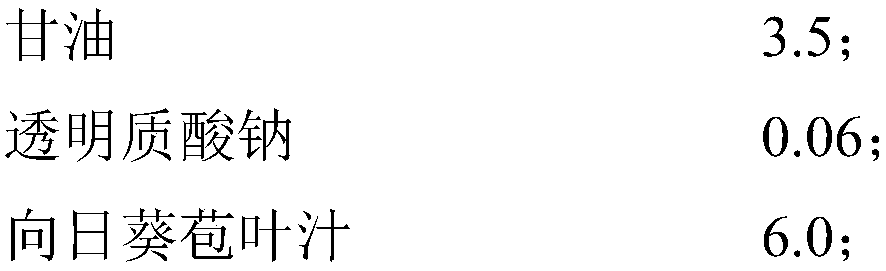

[0077] A hyaluronic acid moisturizing stock solution is made of the following raw materials in parts by weight:

[0078]

[0079] The preparation method is as follows:

[0080] (1) Wash and drain the fresh sunflower bracts and cut them into thin strips with a width of 2-3cm, and completely immerse the thin sunflower bracts in 1.5% ferrous chloride solution, at a constant temperature of 45°C Soak under water for 30 minutes, remove and rinse repeatedly with distilled water for 5 minutes and drain, put the sunflower bracts into a juice extractor and squeeze to obtain sunflower bract juice;

[0081] (2) After rinsing, drying, and pulverizing the cotton husks, add 10 times the amount of water, soak for 1 hour, decoct for 1 hour, filter, and use the filtrate for later use. Repeat extraction of the filter residue once under the same conditions, combine the filtrate, and decompress the obtained filtrate After being concentrated 5 times, the cotton husk extract is obtained;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com