A kind of hydrogen sulfide and sulfur dioxide reactive desulfurization process

A technology of sulfur dioxide and hydrogen sulfide, which is applied in the preparation/purification of sulfur, chemical instruments and methods, separation methods, etc., can solve the problems of difficult purification, low purity of solid sulfur products, harsh liquid-phase reaction conditions, etc. The effect of reducing cost and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

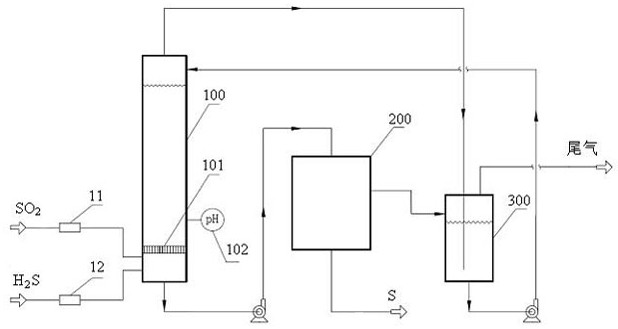

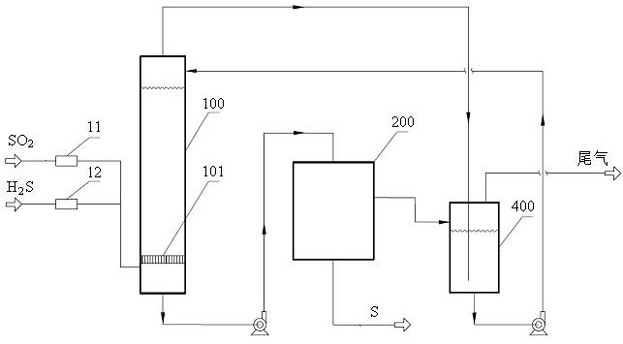

[0045] use figure 1 The hydrogen sulfide and sulfur dioxide reaction desulfurization process of the device shown is as follows:

[0046] Pure SO 2 The gas is passed into the bottom of the reactor 100 through the gas flow meter I11, and the bottom of the reactor 100 is provided with a gas distributor 101, and the aqueous solution of an organic basic compound is installed in the reactor 100 as a reaction solution, SO 2 The gas is dissolved in the reaction solution after passing through the gas distributor 101. An online pH detector 102 is installed on the wall of the reactor 100. When the pH detector 102 shows 6.8, pure H begins to be introduced into the reactor 100. 2S gas is passed into the reactor 100 after passing through the gas flow meter II12, and the liquid in the reactor 100 quickly turns yellow, which shows that the two react immediately to generate sulfur; the product sulfur in the reactor 100 is released from the reactor along with part of the reaction solution The...

Embodiment 2

[0050] use figure 1 The device shown is a process for reactive desulfurization of hydrogen sulfide and sulfur dioxide:

[0051] Except that the organic basic compound solution is a 20% benzylamine solution, other conditions are the same as in Example 1.

[0052] According to the material balance calculation, H 2 The conversion rate of S was 94.1%.

Embodiment 3

[0054] use figure 1 The device shown is a process for reactive desulfurization of hydrogen sulfide and sulfur dioxide:

[0055] In addition to the organic alkaline compound solution is 20% isopropanolamine solution, SO 2 Gas flow rate is 400mL / min, H 2 Except that the flow rate of S gas is 800mL / min, other conditions are the same as embodiment 1.

[0056] According to the material balance calculation, H 2 The conversion rate of S was 97.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com