Preparation method and application of porous g-C3N4 material

A g-c3n4, porous graphite technology, applied in chemical instruments and methods, hydrogen production, inorganic chemistry and other directions, can solve problems such as unfavorable large-scale industrial production, limit preparation efficiency, etc., achieve short synthesis time, improve preparation efficiency, The effect of high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

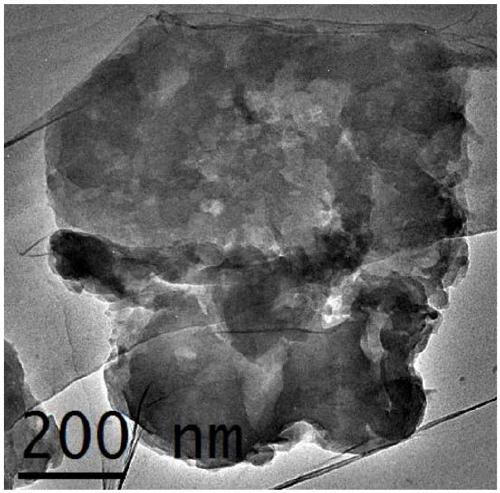

[0024] (1) Weigh 2g of dicyandiamide solid and 1g of urea, and mix them evenly. Grind well to a powder with a mortar and place in a small alumina crucible and seal it with a lid. Put the sealed crucible into a large alumina crucible, evenly cover it with 310g of copper oxide powder, put it in a microwave oven, set the firepower to high fire, heat it in the microwave for 35min, then cool it down to room temperature naturally to obtain a brownish-yellow solid.

[0025] (2) Grind the microwaved solid into powder with a mortar, then put it into a beaker, add 100 ml of deionized water, and process it ultrasonically for 1 hour. The sonicated samples were centrifuged at high speed to remove unreacted precursors and retain g-C 3 N 4 solid. Repeat water washing and centrifugation three times, then put the solid into a watch glass, and heat in a vacuum oven to remove the moisture in the solid. After drying, the samples were ground into powder for future use.

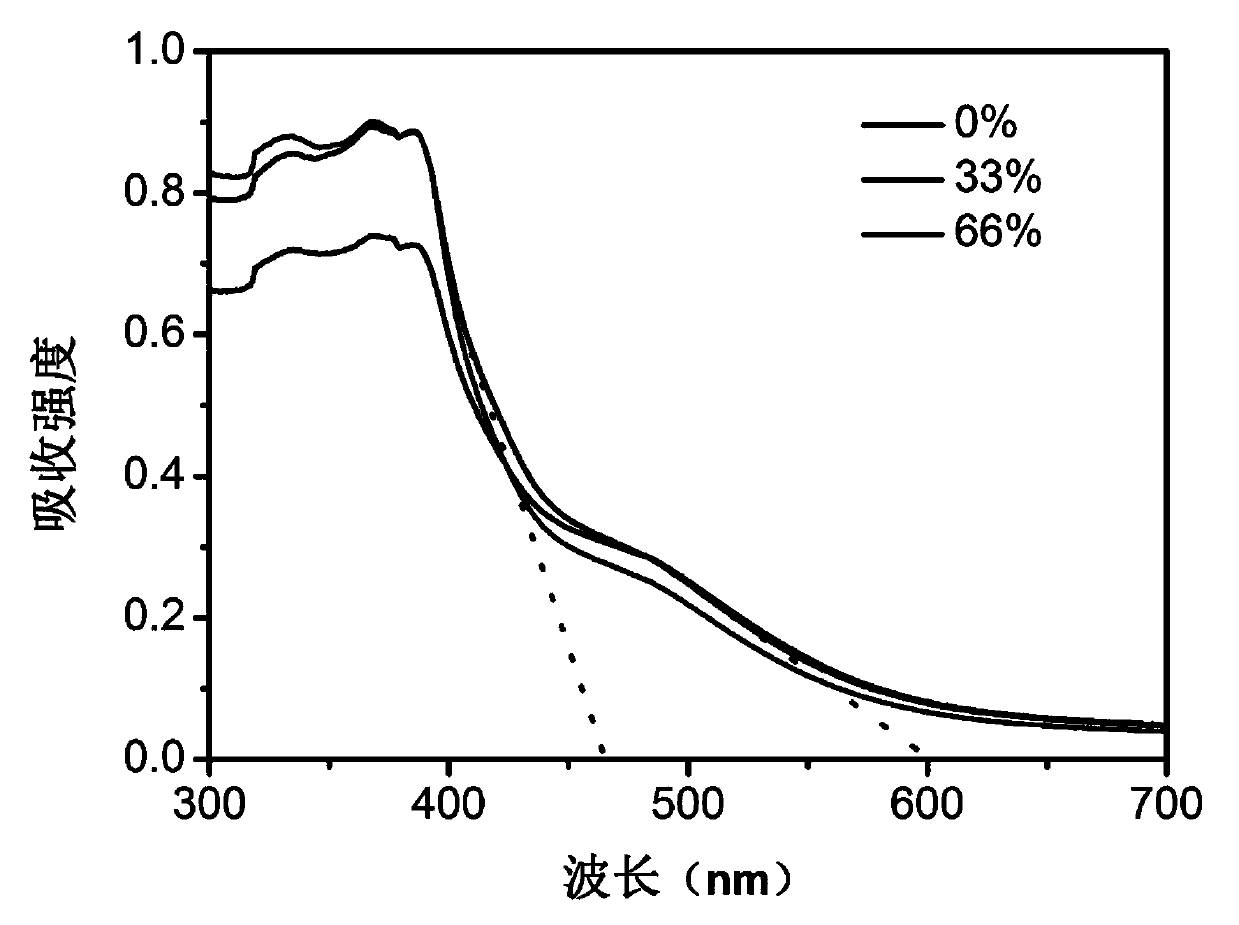

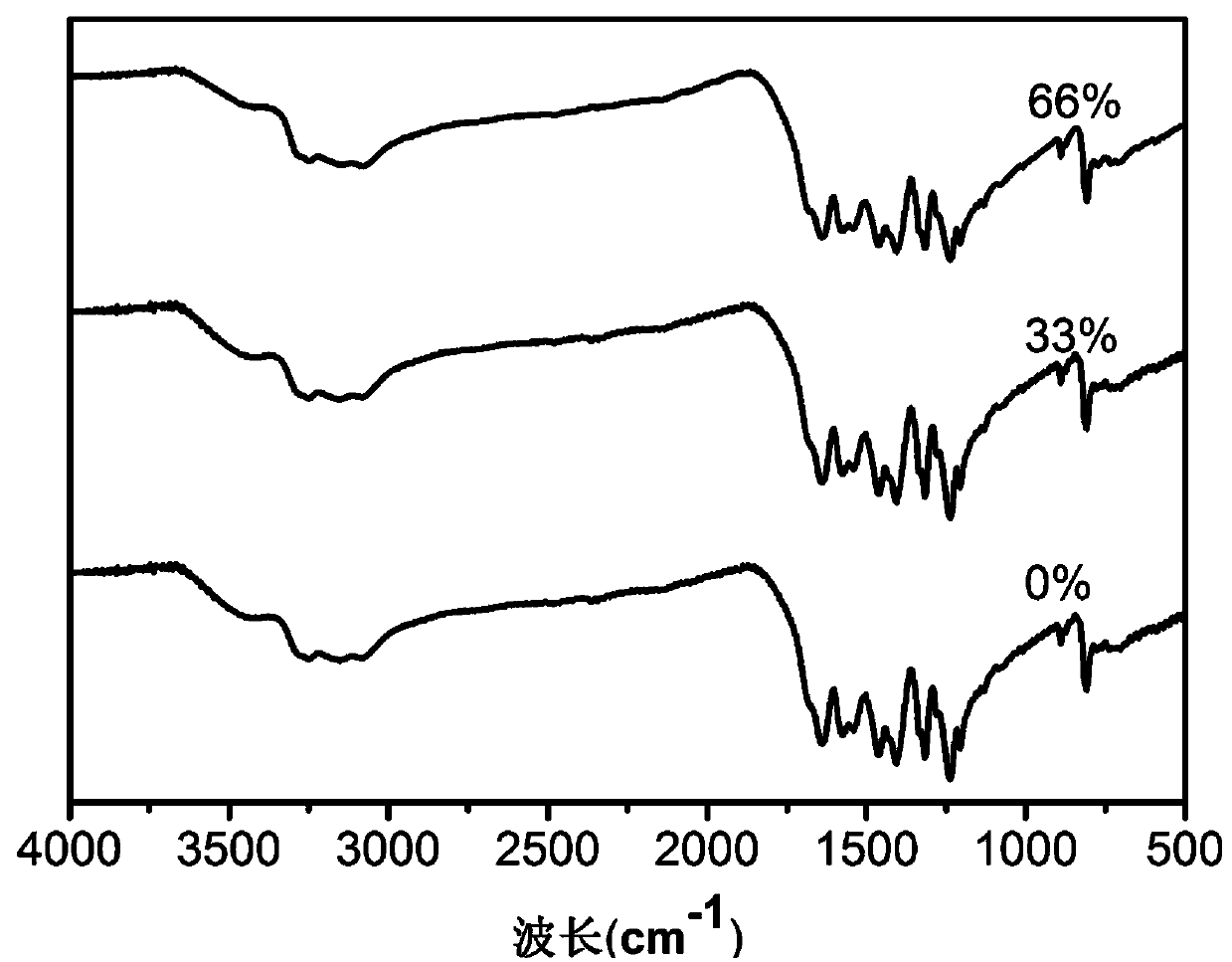

[0026] (3) For the pr...

Embodiment 2

[0028] (1) Weigh 1g of dicyandiamide solid and 2g of urea, and mix them evenly. Grind well to a powder with a mortar and place in a small alumina crucible and seal it with a lid. Put the sealed crucible into a large alumina crucible, cover it evenly with 310g of copper oxide powder, put it in a microwave oven, set the firepower to high fire, heat it in microwave for 35min, then cool it down to room temperature naturally to obtain a brownish-yellow solid.

[0029] (2) Grind the microwaved solid into powder with a mortar, then put it into a beaker, add 100 ml of deionized water, and process it ultrasonically for 1 hour. The sonicated samples were centrifuged at high speed to remove unreacted precursors and retain g-C 3 N 4 solid. Repeat water washing and centrifugation three times, then put the solid into a watch glass, and heat in a vacuum oven to remove the moisture in the solid. After drying, the samples were ground into powder for future use.

[0030] (3) For the prepar...

Embodiment 3

[0035](1) Weigh 1g of dicyandiamide solid and 2g of urea, and mix them evenly. Grind well to a powder with a mortar and place in a small alumina crucible and seal it with a lid. Put the sealed crucible into a large alumina crucible, evenly cover it with 330g of copper oxide powder, put it in a microwave oven, set the firepower to high fire, heat it in microwave for 20min, and cool it down to room temperature naturally to obtain a brownish-yellow solid.

[0036] (2) Grind the microwaved solid into powder with a mortar, then put it into a beaker, add 100 ml of deionized water, and process it ultrasonically for 1 hour. The sonicated samples were centrifuged at high speed to remove unreacted precursors and retain g-C 3 N 4 solid. Repeat water washing and centrifugation three times, then put the solid into a watch glass, and heat in a vacuum oven to remove the moisture in the solid. After drying, the samples were ground into powder for future use.

[0037] (3) For the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com