A method of using industrial waste to reduce the alkalinity of red mud

A technology of industrial waste and red mud, which is applied in the field of environmental protection, can solve the problems of high cost of alkaline regulation of red mud and unsatisfactory effect, so as to increase permeability and water storage capacity, improve the prevention of red mud crusting, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

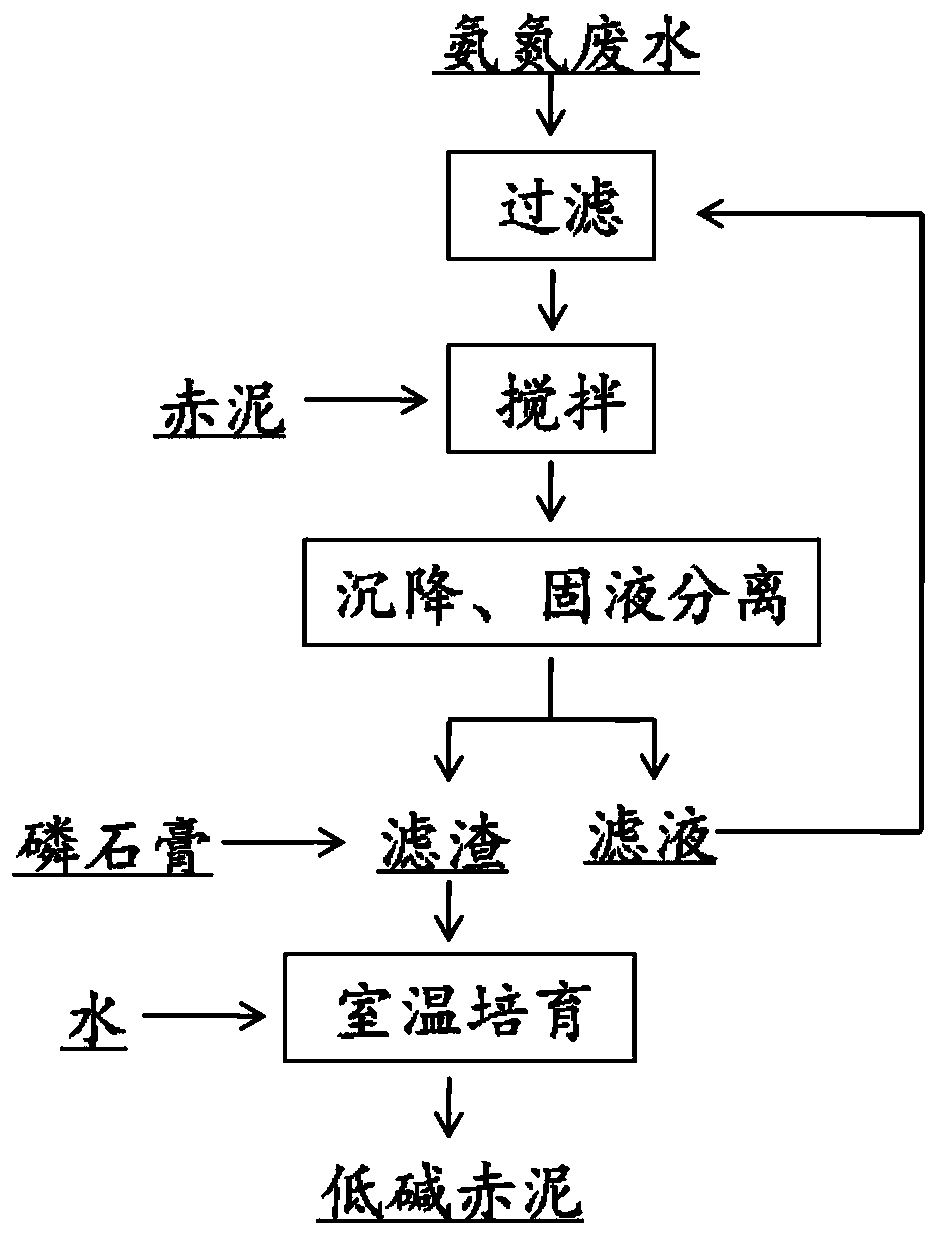

[0033] The method for reducing the alkalinity of red mud by using industrial waste described in this embodiment comprises the following steps:

[0034] (1) Air-dry the red mud from the Bayer process at room temperature, and pass it through a 10-mesh sieve after grinding; use a filter membrane to filter the ammonia-nitrogen waste liquid in the fertilizer industry to obtain ammonia-nitrogen waste water; then NH 4 + Ammonia nitrogen wastewater with a concentration of 80mmol / L was added to the red mud, and the liquid-solid ratio was kept at 3:1, mixed evenly, and stirred for 1 hour with a magnetic stirrer at a speed of 60r / min.

[0035] (2) The red mud slurry in step 1) is naturally settled in a settling tank for solid-liquid separation, and the filtrate is returned to step 1) to obtain red mud filter residue.

[0036] (3) Add the red mud filter residue separated in step 2 to broken phosphogypsum, the mass ratio of phosphogypsum to red mud filter residue is 1:100, keep the field ...

Embodiment 2

[0042] The method for reducing the alkalinity of red mud by using industrial waste described in this embodiment comprises the following steps:

[0043] (1) Air-dry the red mud from the Bayer process at room temperature, and pass through a 10-mesh sieve after grinding; use a filter membrane to filter the ammonia nitrogen waste liquid in the petroleum industry to obtain ammonia nitrogen wastewater, and then NH 4 + Ammonia nitrogen wastewater with a concentration of 90.0mmol / L was added to the red mud, and the liquid-solid ratio was kept at 2:1, mixed evenly, and stirred for 3 hours with a magnetic stirrer at a speed of 80r / min.

[0044] (2) Settling the red mud slurry in step 1) naturally in a settling tank for solid-liquid separation, and returning the filtrate to step 1) to obtain a filter residue.

[0045] (3) The red mud filter residue separated in step 2) is added to the broken phosphogypsum, the mass ratio of phosphogypsum to the red mud filter residue is 1:50, and the fiel...

Embodiment 3

[0048] The method for reducing the alkalinity of red mud by using industrial waste described in this embodiment comprises the following steps:

[0049] (1) Air-dry the red mud from the Bayer process at room temperature, pass through a 10-mesh sieve after grinding; use a filter membrane to filter the ammonia nitrogen waste liquid in the chemical industry to obtain ammonia nitrogen wastewater, and then NH 4 + Ammonia nitrogen wastewater with a concentration of 95mmol / L was added to the red mud, and the liquid-solid ratio was kept at 3:1, mixed evenly, and stirred for 2 hours with a magnetic stirrer at a speed of 80r / min.

[0050] (2) Settling the red mud slurry in step 1) naturally in a settling tank for solid-liquid separation, and returning the filtrate to step 1) to obtain a filter residue.

[0051] (3) The red mud filter residue separated in step 2) is added to the crushed phosphogypsum, the mass ratio of phosphogypsum to the red mud filter residue is 1:50, and the field wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com